Air Compressor

Air Compressor

Gongtong produces rotary vane air compressors with coolant injection featuring original solutions, which is the result of our constant efforts in research and development.

The air compressor, with pressure from 2.5 to 10 bar (g) and capacity from 67 to 2.037 m/h, provides both high performance and flexibility for industrial applications. As with all Gongtong compressors, the rotary vane principle and the patented system of intensive coolant injection guarantee constant efficiency and air purity over decades of operation. Through fully automatic operation, our air compressor adapt to a variety of uses with no compromise to durability. The compact design allows easy integration and maximizes natural air cooling, which results in higher overall performance.

Complying with the majority of international regulations for environmental safety and ergonomics, this air compressor ensures considerable energy savings, low noise levels and easy, trouble-free operation for the lowest Life Cycle Cost.

Main Features

1. Single-stage rotary vane technology represents the simplest and most reliable solution for compressed air production.

2. Constant performance thanks to active sealing and few moving parts subject to wear.

3. This air compressor comes with two bearings which ensure limited friction in order to guarantee negligible power loss and low maintenance.

4. Direct coupling to 4-pole motor at 1.450rpm for 50Hz, with IP55 protection for a low rotation speed and long durability.

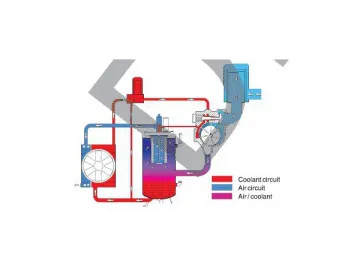

5. Intensive coolant injection for low compression work and consequently low power consumption.

6. Idle running with lubrication through suction that reduces the energy requirement to 18% of installed power.

7. High efficiency aluminum coolers are available in the air compressor, which guarantees constant performance, even in extreme climate conditions.

8. Motor fan for air-coolant and air-air coolers. The air flow, crossing the cabin, keeps the installed components at low temperature.

9. Thermoregulation of the coolant flow towards the cooler, to run in any operating condition.

Components

1. The air compressor adopts Plug and Play unit, requiring no foundations and fully equipped for operation.

The connection to the electric network and to the compressed air line are ready for immediate use.

2. Coolant separation in 3 phases

Centrifugal separation, mechanical trap and final coolant separation through a borosilicate filter element with coolant recovery. The result is a remarkable purity of the compressed air with residual coolant carry over 1 mg/m.

3. Vertical layout up to A60 for space economy.

4. Soundproof cabin [80dB (A)] for low noise.

5. The air compressor is designed with removable side panels for high accessibility to any machine component, allowing simple, quick and inexpensive maintenance.

6. Filtration cells, easily extractable and washable to keep the machine interior and the coolers clean.

7. Cyclone effect air filter, for higher efficiency.

8. Electropneumatic control panel to manage operation in best conditions.

9. Hard aluminium alloy vanes for heavy duty24/7 operation.

10. Condensate separator with drainer to eliminate compressed air waste.

11. Air-end sturdy construction for round the clock operation.

12. Instruction manual is provided along with the air compressor, complete and user-friendly.

13. Service diary to record all maintenance activity.

Specifications

Model | Pressure Range | Capacity | Nominal Power | Noise Level | Overall Dimensions | Weight | ||||||||||

50HZ | 60HZ | 50HZ | 60HZ | 50HZ | 60HZ | L×W×H | ||||||||||

Bar (g) | PSI (g) | m3/h | cfm | m3/h | cfm | kW | HP | kW | HP | dB (A) | mm | kg | lbs | |||

A10 | A10.4 | 2.5-4 | 36-58 | 70 | 41 | 83 | 49 | 5.5 | 7.5 | 6.5 | 9 | 72 | 73 | 1.275×706×1.600 | 300 | 661 |

A10.8 | 4-8 | 58-116 | 68 | 40 | 75 | 45 | 7.5 | 10 | 9 | 12 | ||||||

A10.10 | 8-10 | 116-145 | 67 | 40 | 74 | 44 | 9 | 12 | 10 | 14 | ||||||

A20 | A20.4 | 2.5-4 | 36-58 | 106 | 62 | 126 | 74 | 9 | 12 | 10 | 14 | 72 | 73 | 1.275×706×1.600 | 420 | 926 |

A20.8 | 4-8 | 58-116 | 102 | 60 | 115 | 68 | 11 | 15 | 13 | 18 | ||||||

A20.10 | 8-10 | 116-145 | 101 | 59 | 113 | 66 | 15 | 20 | 18.5 | 24 | ||||||

A30 | A30.4 | 2.5-4 | 36-58 | 175 | 103 | 207 | 122 | 15 | 20 | 18.5 | 24 | 72 | 73 | 1.275×706×1.700 | 440 | 970 |

A30.8 | 4-8 | 58-116 | 168 | 99 | 189 | 112 | 18.5 | 25 | 22 | 30 | ||||||

A30.10 | 8-10 | 116-145 | 167 | 98 | 187 | 110 | 22 | 30 | 26 | 36 | ||||||

A35 | A35.4 | 2.5-4 | 36-58 | 210 | 124 | 249 | 146 | 18.5 | 25 | 22 | 30 | 73 | 74 | 1.275×706×1.700 | 440 | 970 |

A35.8 | 4-8 | 58-116 | 204 | 120 | 230 | 135 | 22 | 30 | 26 | 36 | ||||||

A35.10 | 8-10 | 116-145 | 202 | 118 | 227 | 133 | 30 | 40 | 35 | 48 | ||||||

A60 | A60.4 | 2.5-4 | 36-58 | 362 | 213 | 429 | 252 | 30 | 40 | 35 | 48 | 72 | 73 | 1.275×1.050×1.900 | 1.015 | 2.238 |

A60.8 | 4-8 | 58-116 | 355 | 209 | 408 | 240 | 37 | 50 | 42 | 60 | ||||||

A60.10 | 8-10 | 116-145 | 353 | 208 | 405 | 238 | 45 | 60 | 50 | 72 | ||||||

A90 | A90.4 | 2.5-4 | 36-58 | 660 | 388 | 781 | 459 | 45 | 60 | 50 | 72 | 73 | 74 | 1.380×1.280×2.200 | 1.250 | 2.756 |

A90.8 | 4-8 | 58-116 | 550 | 324 | 633 | 372 | 55 | 75 | 65 | 90 | ||||||

A90.10 | 8-10 | 116-145 | 548 | 322 | 628 | 369 | 75 | 100 | 90 | 120 | ||||||

A120 | A120.4 | 2.5-4 | 36-58 | 800 | 471 | 947 | 557 | 75 | 100 | 90 | 120 | 74 | 75 | 2.060×1.070×2.000 | 1.600 | 3.527 |

A120.8 | 4-8 | 58-116 | 755 | 444 | 868 | 510 | 75 | 100 | 90 | 120 | ||||||

A120.10 | 8-10 | 116-145 | 752 | 442 | 861 | 506 | 90 | 120 | 100 | 144 | ||||||

A180 | A180.4 | 2.5-4 | 36-58 | 1.595 | 938 | 1.889 | 1.111 | 132 | 177 | 150 | 212 | 78 | 79 | 2.570×1.570×2.000 | 2.300 | 5.071 |

A180.8 | 4-8 | 58-116 | 1.110 | 653 | 1.277 | 751 | 110 | 150 | 132 | 180 | ||||||

A180.10 | 8-10 | 116-145 | 1.105 | 650 | 1.270 | 747 | 132 | 177 | 150 | 212 | ||||||

A260 | A260.4 | 2.5-4 | 36-58 | 1.720 | 1.012 | 2.037 | 1.198 | 160 | 215 | 180 | 258 | 79 | 80 | 2.870×1.570×2.000 | 2.800 | 6.173 |

A260.8 | 4-8 | 58-116 | 1.525 | 897 | 1.760 | 1.035 | 160 | 215 | 180 | 258 | ||||||

A260.10 | 8-10 | 116-145 | 1.518 | 893 | 1.740 | 1.023 | 200 | 270 | 230 | 324 | ||||||

Gongtong Mechanical Equipment Company is an ISO9001:2008 certified manufacturer of air compressor in China. Our company is mainly engaged in the production and sales of CO2 recovery plant, air separation unit, cryogenic liquid storage tank, oil storage tank and so on. Located in Zhuhai, Guangdong, we are given a convenient transportation condition which can help you reduce the international transportation costs. Thank you for your attention. If you would like to know more about our other products, please turn to the corresponding pages. We welcome you to contact us and we look forward to working with you.

Links:https://www.globefindpro.com/products/110923.html

-

Energy Saving Lamp, Candle Shape CFL

Energy Saving Lamp, Candle Shape CFL

-

Cryogenic Liquid Piston Pump

Cryogenic Liquid Piston Pump

-

Cryogenic Liquid Transportation Tanker

Cryogenic Liquid Transportation Tanker

-

Ambient Vaporizer

Ambient Vaporizer

-

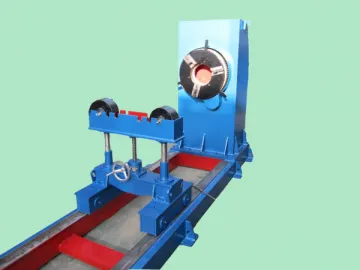

Movable Welding Manipulator (Column Boom Manipulator)

Movable Welding Manipulator (Column Boom Manipulator)

-

Cryogenic Liquid Centrifugal Pump

Cryogenic Liquid Centrifugal Pump

-

Cryogenic Liquid Storage Tank (Flat Bottom)

Cryogenic Liquid Storage Tank (Flat Bottom)

-

High Purity Nitrogen Plant

High Purity Nitrogen Plant

-

Head To Tail Welding Positioner

Head To Tail Welding Positioner

-

Steam / Electric Heating Vaporizer

Steam / Electric Heating Vaporizer

-

Rotary Welding Manipulator (Fixed Belt Column Boom Manipulator)

Rotary Welding Manipulator (Fixed Belt Column Boom Manipulator)

-

CNC Cutting Machine

CNC Cutting Machine