Economic Automatic Concrete Block Production Line

Economic Automatic Concrete Block Production Line

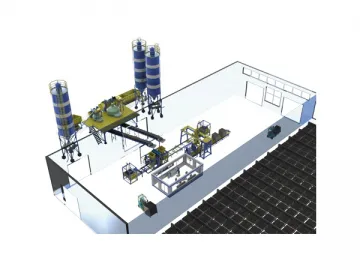

REIT economic automatic concrete block production line is used for the manufacturing of various pavers, kerbstones, hollow and solid blocks, etc. It consists of three main parts, including batching and mixing plant, concrete block making machine and controlling system.

Features

1. We manufacture this concrete block production line using advanced German technology, with our own proprietary intellectual property right.

2. This equipment is known for high automation, high productivity, great reliability and low failure rate

3. Our product is accompanied by superior customer service, so you can feel secure in your purchase.

More Information

International markets: the Middle East, Libya, Algeria, Indonesia, India, Russia, Pakistan, South Korea, North Korea, USA, etc.

Certificates: CE and ISO9001

Time of finishing an order: 2-3 months

Payment term: T/T and L/C

Spare parts: free spare parts within the warranty period

Voltage requirement: according to customer's specific requirements

REIT RTQT9, RTSQD12, RTSQT6, RTSQT4 block machine is used for economic automatic production line to have different capacity of production lines. It's designed for small scale investment. This production line is made up of reduced parts, which effectively lowers the cost. However, it requires more workers. The REIT economical automatic concrete block production line includes four parts

(1) Batching and mixing plant

(2) Concrete block making machine

(3) Mobile stacking device

(4) Controlling system

(1) Batching and mixing plant

There are two sets of batching and mixing equipment for base concrete and face concrete separately. All materials used, like aggregate, cement and pigment, are weighed automatically and accurately through computer control. The mixer is twin shaft horizontal type.

It is essential for high quality final products. Special Features

In technique

Accurate weighing

Even and quick mixing

In equipment

All material are weighed and controlled by computer

Twin shaft horizontal mixer

(2) Concrete block making machine

Compacting and vibrating system-Block making machine The block making machine uses advanced vibration technology and REIT patent multi-shaft vibrator, resulting in even vibration on the table. The frequency and amplitude are variable according to different materials and different products. With foam plate insert device, the block machine can produce heat insulation blocks. The cycle time is greatly shortened due to the utilization of hydraulic driven fast feeding device and REIT low speed cruising control technology.

This part is key for high quality products.

Special Features

In technique

Advanced vibration technology

Variable frequency and amplitude

Vibration isolation

Low speed cruising control

In equipment

Multi-shafts vibrator with high frequency

Inverter control

Floating vibration table

Hydraulic driving two arms feeding system

Advanced PLC control system

(3) Mobile Stacking Device

This device is designed to transport the pallets with wet products and stack them automatically, two pallets once. It is of bridge frame structure and is controlled by PLC. Two sets of holders at both side of frame hold pallets with wet products. Under the both supports there are two sets of driving and driven wheels.

(4) Electric Control Group

The electric control group adopts world famous brand PLC and the power unit is housed in a control desk. The desk includes joy-sticks for manual machine operation and an integrated display for data input, output and error diagnosis system. The color monitor is equipped with user-friendly interface and diagram display, which makes it convenient and effective for the operator to operate and control the whole production line. The concrete block production line can be controlled fully automatically, semi-automatically and manually through this control group. It is the I/O operator and machine.

Links:https://www.globefindpro.com/products/110961.html

-

PAR16 4W/6W LED Par Light

PAR16 4W/6W LED Par Light

-

LED Tube Light

LED Tube Light

-

Automatic Concrete Block Production Line

Automatic Concrete Block Production Line

-

PAR38 12W/18W LED Par Light

PAR38 12W/18W LED Par Light

-

LED Candle

LED Candle

-

PAR20 5W/7W LED Par Light

PAR20 5W/7W LED Par Light

-

A60 7W/9W/10W/12W LED Bulb

A60 7W/9W/10W/12W LED Bulb

-

Concrete Block Making Machine RTQT9

Concrete Block Making Machine RTQT9

-

MR16 GU5.3 LED Spotlight

MR16 GU5.3 LED Spotlight

-

Concrete Block Making Machine RTQT15

Concrete Block Making Machine RTQT15

-

24W LED Downlight

24W LED Downlight

-

Energy Saving Lamp, Cubelite Shape CFL

Energy Saving Lamp, Cubelite Shape CFL