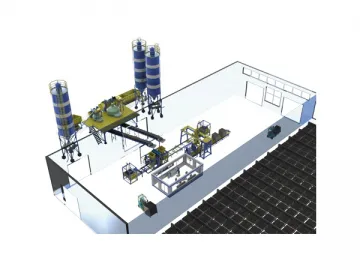

Fully Automatic Concrete Block Production Line

Fully Automatic Concrete Block Production Line

This page shows our fully automatic concrete block production line, which is one of our most popular products. This line is designed and manufactured using our years of experience and advanced technology from Germany. Hence, REIT concrete block production line has the advantages of low failure rate, high productivity, high automation and great reliability.

REIT fully automatic concrete block production line consists of five parts

1. Batching and mixing plant

2. Concrete block making machine

3. Handling system

4. Cubing system

5. Controlling system

Applications

This concrete block production line is suitable for making pavers, kerbstones, hollow and solid blocks, etc., which are widely used as construction building material, road construction material and landscaping material, etc.

More Information

International markets: the Middle East, Libya, Algeria, Indonesia, India, Russia, Pakistan, South Korea, North Korea, USA, etc.

Certificates: CE and ISO9001

Time of finishing an order: 2-3 months

Payment term: T/T and L/C

Spare parts: free spare parts within the warranty period

Voltage requirement: according to customer's specific requirements

REIT RTQT15, RTQT12, RTQT9 block machine is used for fully automatic production line to have different capacity of production lines. This production line is designed for large scale investment. The whole production line requires only 5 to 6 workers.

The REIT fully automatic concrete block production line consists of five parts

(1) Batching and mixing plant

(2) Concrete block making machine

(3) Handling system

(4) Cubing system

(5) Controlling system

(1) Batching and mixing plant

There are two sets of batching and mixing equipment for base concrete and face concrete separately. All materials used including aggregate, cement and pigment are automatically and accurately weighed through computer control. The system is equipped with microwave moisture measurement and accurate water metering devices controlled by computer. The use of advanced planetary mixers ensures fast and uniform mixing.

It is essential for high quality final products.

Special Features

In technique

Accurate weighing

Accurate moisture

Even and quick mixing

In equipment

All materials are weighed and controlled by computer

Moister and water controlled by computer

Planetary mixers

(2) Concrete block making machine

Compacting and vibrating system-Block making machineAs the block making machine adopts advanced vibration technology and REIT patent multi-shaft vibrator, the vibration on the table is even. The frequency and amplitude can be adjusted according to different materials and products. The hydraulic driven fast feeding device and REIT low speed cruising control technology are used to shorten the cycle time. The use of foam plate insert device enables the block machine to produce heat insulation blocks.

It is the key for high quality products.

Special Features

In technique

Advanced vibration technology

Variable frequency and amplitude

Vibration isolation

Low speed cruising control

In equipment

Multi-shaft vibrator with high frequency

Inverter control

Floating vibration table

Hydraulic driving two-arm feeding system

Advanced PLC control system

(3) Handling system

The finger car and green block conveyor are equipped with inverters for smooth operation. There are mechanical position device and interlock and self-lock function in the control system for finger car so it is operating safely and reliably. The elevator and lowerator are equipped with REIT patent synchronized device. The finger car that can turn around 180° is optional.

It is the transportation protection for high quality final products.

Special Features

Finger car and green block conveyors are controlled by inverter. There are patent synchronized device.

(4) Automatic Cuber System

REIT cuber is fully automatic. The cubing layers, height and style are adjustable. The cuber can move, lift and rotate automatically at the same time. The horizontal movement is inverter controlled gear and pinion rack driven. The vertical lifting is digital code controlled hydraulic driven. The rotation is gear and tooth ring driven.

It is the package protection for high quality final products.

Special Features

Inverter controlled gear and pinion rack driving movement

Code controlled hydraulic up and down

Advanced hydraulic clamp

Gear and tooth ring driving rotation

Reliable hydraulic station with elements from renowned suppliers

(5) Electric Control Group

The electric control group adopts world famous brand PLC. The power unit is housed in a control desk which includes joy-sticks for manual machine operation and an integrated display for data input, output as well as error diagnosis system. The color monitor is equipped with user-friendly interface and diagram display, enabling the operator to operate and control the block production line conveniently and effectively. The whole line can be controlled fully automatically, semi-automatically and manually through this control group.

It is the I/O operator and machine.

Links:https://www.globefindpro.com/products/110968.html