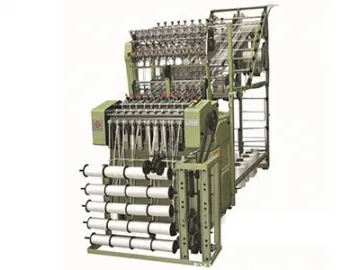

Double Decker Needle Loom

TXF 10/25

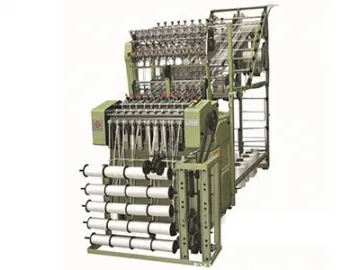

TXF6/80

Parameters

Optional devices

Three roller automatic rubber feeding device

Double roller automatic rubber feeding device

Double take off wheel device

Double take off roller device

Automatic weft feeding device

Belt weft feeding device

Double weft double latch needle device

Double hook and double latch needle device

Frequency converter

Counter

Front / rear automatic take-up machine

Rear creel number

Features

The compact and advanced machine structure ensures the needle loom features a small footprint.

Main parts are produced using CNC equipment with a process precision of 0.005mm, ensuring machine durability and reducing the depreciation rate, offering more benefits to the user. Lubrication is carried out using an automatic-circulation lubrication system. A broken yarn automatic stop function provides effective control over fabrics used while saving both time and labor. The yarn feeding device utilizes a belt transmission with a gear for flexible speed shifting. This ensures weft yarn feeding stability and ensures the machine is suitable for the production of a variety of webbing types.

TXF6/80

With the webbing width range of 1mm to 25mm, the double decker loom is known for its exceptionally high productivity. It carries out the production of two layer webbing, with a maximum of 20 weaving heads.

Parameters

| Model | Heads / lines | Max. width(mm) | Heald frame | Pick pepeat | Weft density(cm) | Machine rotation speed(r/min) |

| D10/25 | 10-20 | 25 | 12(16) | 8-48 | 3.5-36.7 | 1000-1200 |

Optional devices

Three roller automatic rubber feeding device

Double roller automatic rubber feeding device

Double take off wheel device

Double take off roller device

Automatic weft feeding device

Belt weft feeding device

Double weft double latch needle device

Double hook and double latch needle device

Frequency converter

Counter

Front / rear automatic take-up machine

Rear creel number

Features

The compact and advanced machine structure ensures the needle loom features a small footprint.

Main parts are produced using CNC equipment with a process precision of 0.005mm, ensuring machine durability and reducing the depreciation rate, offering more benefits to the user. Lubrication is carried out using an automatic-circulation lubrication system. A broken yarn automatic stop function provides effective control over fabrics used while saving both time and labor. The yarn feeding device utilizes a belt transmission with a gear for flexible speed shifting. This ensures weft yarn feeding stability and ensures the machine is suitable for the production of a variety of webbing types.

Scan QR to Read

Links:https://www.globefindpro.com/products/11126.html

Links:https://www.globefindpro.com/products/11126.html

Recommended Products

-

Zipper Tape Needle Loom

Zipper Tape Needle Loom

-

Bobbin Winder

Bobbin Winder

-

Crossflow Blower & Fan

Crossflow Blower & Fan

-

YJF 62 C-Frame Shaded Pole Motor

YJF 62 C-Frame Shaded Pole Motor

-

Tape Packing Machine (Box Packing)

Tape Packing Machine (Box Packing)

-

Ventilation System, Motor

Ventilation System, Motor

-

Tape Rolling Machine

Tape Rolling Machine

-

YJF 82 Q-Frame Shaded Pole Motor

YJF 82 Q-Frame Shaded Pole Motor

-

Yarn Warping Machine

Yarn Warping Machine

-

Home Appliances, Motor

Home Appliances, Motor

-

Crochet Knitting Machine

Crochet Knitting Machine

-

Measuring, Roll and Spool Winding Machine

Measuring, Roll and Spool Winding Machine

Hot Products