UV Curing

UV curing machine is widely used for curing UV coating on substrate of wood, synthetic board, plastic, glass, metal and etc.

Features The long-time irradiation of UV light results in a high temperature in light box, which will shorten the machine service life. Therefore, XMF UV curing equipment adopts a spilt type UV light box—each UV lamp is equipped with an independent light box and an independent cooling system. Compared to the integrated light box, the split type features faster cooling speed and achieves lower box temperature and longer working life. Each UV lamp is independently controlled. The intensity of light can be regulated according to the characteristics of UV coating and two modes are optional—lowlight or highlight. As the light energy will gradually attenuate as the long-time usage, a height adjustment design is added for each lamp of the curing machine. When an UV lamp has no enough energy, you can reduce the height of this lamp to guarantee the curing performance and extend its service life. Working principleThe pattern which customer needs are engraved on the pattern roller. After adjusting the distance between the pattern roller and the substrate, due to the large pressure of the pattern roller, it will emboss a stereo grain on the substrate. A built-in heating device can heat the pattern roller to 400 ℃ and the heated embossing pattern is more fixed and unchangeable.

Optional model Double lamp UV Curing machineDouble lamp UV Curing machine is designed to fix or dry putty, transparent or colored base coat and top coat. The double lamp design allows for simultaneous usage of different coatings and each lamp can be independently regulated to suit customer’s coating fluid. The double lamp UV curing equipment is able to immediately cure the coating film, which improves the productivity, reduces labor cost and makes this kind of curing machine ideal for flow-line production. This curing machine is perfect for curing the base coat or top coat of wood board, medium fiber board, triamine board, acrylic board, aluminum board, PVC board and etc. with 100% efficiency.

Spilt type design of the light box achieves good cooling performance and lower box temperature. Two light boxes are all equipped with a 0.75KW cooling fan with an independent lamp cooling channel. Adjustable lamp height and reasonable light box design for easy assembly and disassembly. A set of gallium lamp light source system, 11KW transformer, 13UF capacitor, L1450 long lamp tube. A set of mercury lamp light source system, 11KW transformer, 13UF capacitor, L1450 long lamp tube. Thicker stainless-steel tube chain conveyor with an interval of 3.81CM. Independent control for each group of lamps. Lowlight or highlight mode can be switched to according to the coating type and technical requirements. The cooling fan system features automatic delay cooling and automatic delay shutdown functions.

Note: The common light sources include potassium lamp and mercury lamp which can be chosen according to the actual demands.

Parameter| Voltage | AC 380V three-phase four-wire |

| Frequency | 50HZ |

| Total power | 25KW |

| Working width | 0-1320mm |

| Working thickness | 2-80mm |

| Minimum working length | 300mm |

| Feeding speed | 0-20m/min |

| Dimension | 2000mm×2000mm×1700mm |

Triple lamp UV curing machine

Triple lamp UV Curing machine is designed to fix or dry putty, transparent or colored base coat and top coat. The triple lamp design allows for simultaneous curing of different coatings and each group of lamps can be independently regulated to suit customer’s coating fluid. The UV curing equipment is able to immediately cure the coating film, which improves the productivity, reduces labor cost and makes this kind of curing machine ideal for flow-line production. This triple lamp UV curing machine is perfect for 100% drying the base coat or top coat of wood board, medium fiber board, triamine board, acrylic board, aluminum board, PVC board and etc.

FeaturesSpilt type design of the light box achieves good cooling performance and lower box temperature. Three light boxes are all equipped with a 0.75KW cooling fan with an independent lamp cooling channel. Adjustable lamp height and reasonable light box design for easy assembly and disassembly. One set of gallium lamp light source system, 11KW transformer, 13UF capacitor, L1450 long lamp tube. Two sets of mercury lamp light source system, 11KW transformer, 13UF capacitor, L1450 long lamp tube. Thicker stainless-steel tube chain conveyor with an interval of 3.81CM. Independent control for each group of lamps. Lowlight or highlight mode can be switched to according to the coating type and technical requirements. The cooling fan system features automatic delay cooling and automatic delay shutdown functions.

Note: The common light sources include potassium lamp and mercury lamp which can be chosen according to the actual demands.

Parameter| Voltage | AC three-phase four-wire380V |

| Frequency | 50HZ |

| Total power | 36KW |

| Working width | 0-1320mm |

| Working thickness | 2-80mm |

| Minimum working length | 300mm |

| Feeding speed | 0-20m/min |

| Dimension | 2500mm×2000mm×1700mm |

Six lamp UV curing machine

Six lamp UV Curing machine is designed to dry the base coat or top coat on the multi sides of the irregular-shaped substrates.

The six lamp design allows for simultaneous curing of different coatings and each group of lamps can be independently regulated to suit customer’s coating fluid. The UV curing equipment is able to cure the coating film immediately, which improves the productivity, reduces labor cost and makes this kind of curing machine ideal for flow-line production. This six lamp UV curing machine is perfect for 100% curing the coating of wood board, medium fiber board, triamine board, acrylic board, aluminum board, PVC board and etc.

FeaturesSpilt type design of the light box achieves good cooling performance and lower box temperature. Three groups of light boxes are all equipped with two 0.75KW cooling fans with an independent lamp cooling channel. Adjustable lamp height and reasonable light box design for easy assembly and disassembly. Six groups of lamps arrangement—three on front, one on each two side and one on bottom, allowing to all-around curing for irregular-shaped workpieces. One set of gallium lamp light source system, 11KW transformer, 13UF capacitor, L1450 long lamp tube. Two sets of mercury lamp light source system, 11KW transformer, 13UF capacitor, L1450 long lamp tube. Thicker stainless-steel tube chain conveyor with an interval of 3.81CM. Independent control for each group of lamps. Lowlight or highlight mode can be switched to according to the coating type and technical requirements. The cooling fan system features automatic delay cooling and automatic delay shutdown functions.

Note: The common light sources include potassium lamp and mercury lamp which can be chosen according to the actual demands.

Parameter| Voltage | AC three-phase four-wire380V |

| Frequency | 50HZ |

| Total power | 73KW |

| Working width | 0-1320mm |

| Working thickness | 2-80mm |

| Minimum working length | 300mm |

| Feeding speed | 0-20m/min |

| Dimension | 3500mm×2000mm×1700mm |

Links:https://www.globefindpro.com/products/11167.html

-

Jacquard Loom, Electronically Controlled Narrow Fabric Loom

Jacquard Loom, Electronically Controlled Narrow Fabric Loom

-

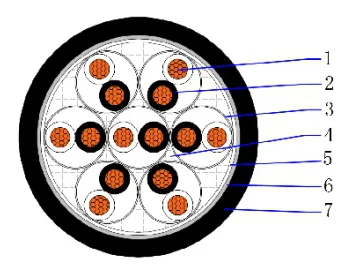

CU/PVC/OS/PVC 500V PVC insulated overall screen instrumentation cable

CU/PVC/OS/PVC 500V PVC insulated overall screen instrumentation cable

-

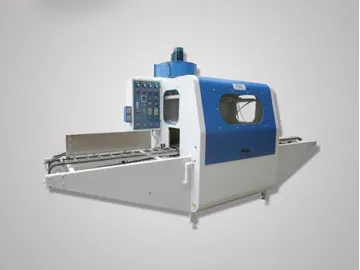

Linear Spraying Machine

Linear Spraying Machine

-

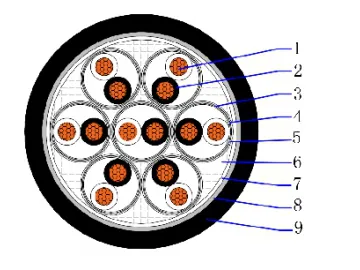

CU/PE/ISOS/PVC 500V PE insulated individual & overall screen instrumentation cable

CU/PE/ISOS/PVC 500V PE insulated individual & overall screen instrumentation cable

-

Single-Roll Coating Machine

Single-Roll Coating Machine

-

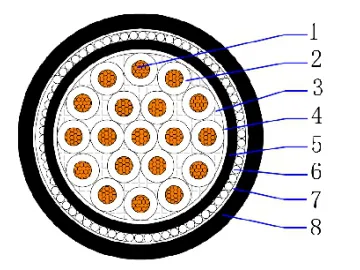

CU/PVC/PVC/SWA/PVC 0.6/1kV armoured control cable

CU/PVC/PVC/SWA/PVC 0.6/1kV armoured control cable

-

TFFN Copper Wire

TFFN Copper Wire

-

Jacquard Loom (Multicolor Weft Pattern Forming)

Jacquard Loom (Multicolor Weft Pattern Forming)

-

Low-Voltage Secondary Distribution Cable

Low-Voltage Secondary Distribution Cable

-

TC Cable, Tray cable

TC Cable, Tray cable

-

THHN Copper Wire, THHN Aluminum Wire

THHN Copper Wire, THHN Aluminum Wire

-

DLO Diesel Locomotive Cable

DLO Diesel Locomotive Cable