Curtain Coating

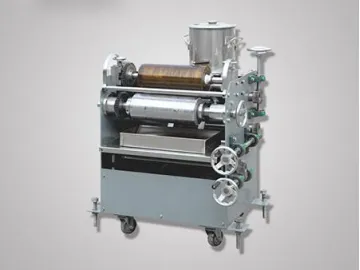

Function Curtain coating is a coating process in which the substrate passes through the coating fluid curtain to form an even finishing film on the surface. The curtain coating is mainly designed for flat or nearly-flat substrates. The curtain-coated film features high smoothness, high decorativeness and mirror-surface effects, which other coating processes can’t achieve. Functions of XMF curtain coating machine Coating weight is manually adjustable by controlling the spacing between roll blade and the substrate. The curtain coating film is thicker to protect the workpiece. XMF curtain coaters are available in coating weight from 80~200g/㎡ and thickness≤4mm. We can provide you with a custom curtain coating solution based on the pattern, shape and dimension of your individual products. Welcome to contact us for more suggestions. Applications  Two factors may influence the coating performance Air quality. Curtain coating needs a dust-free environment. Dust will result in a granular coating surface to affect the decorativeness. Bubbles in the coating fluid. The re-used paint is easy to contain bubbles caused by impurities, which will affect the coating quality. In order to solve this problem, XMF curtain coater is equipped with an independent large-capacity reservoir with an inside 6-layer filter device, which is capable of filtering impurities and eliminating the bubbles. Features The flatness of the curtain finishing film is affected by the quality and stability of the doctor blade. Hence XMF adopts an all-aluminum doctor blade which will be rough processed, fine polished, chrome-plated and adjusted to ensure higher stability. Split-type conveyor. Compared to the one-piece conveyor, the two-stage conveyors can avoid the uneven finish film caused by the machine vibration. Siemens motor and all-aluminum pump head are adopted for fuel feed pump, which increases the pump stability and eliminating the bubbles caused by oil pumping vibration to provide a better coating quality. One-button start of doctor blade. Higher safety offered than the manual start. Parameter

Two factors may influence the coating performance Air quality. Curtain coating needs a dust-free environment. Dust will result in a granular coating surface to affect the decorativeness. Bubbles in the coating fluid. The re-used paint is easy to contain bubbles caused by impurities, which will affect the coating quality. In order to solve this problem, XMF curtain coater is equipped with an independent large-capacity reservoir with an inside 6-layer filter device, which is capable of filtering impurities and eliminating the bubbles. Features The flatness of the curtain finishing film is affected by the quality and stability of the doctor blade. Hence XMF adopts an all-aluminum doctor blade which will be rough processed, fine polished, chrome-plated and adjusted to ensure higher stability. Split-type conveyor. Compared to the one-piece conveyor, the two-stage conveyors can avoid the uneven finish film caused by the machine vibration. Siemens motor and all-aluminum pump head are adopted for fuel feed pump, which increases the pump stability and eliminating the bubbles caused by oil pumping vibration to provide a better coating quality. One-button start of doctor blade. Higher safety offered than the manual start. Parameter

Gallery

The curtain coater is perfect for flat coating or profiled multi-surface coating of wood, synthetic board, plastic, glass, metal and other materials.

| Voltage | AC three phase four wire 380V |

| Frequency | 50HZ |

| Total power | 3.7KW |

| Working width | 0-1320mm |

| Min. working length | 300mm |

| Feeding speed | 0-60m/min |

| Feeding power | 0.75KW×2 |

| Conveyor pulley dimension | ¢130×1350 mm |

| Pump power | 2.2KW |

| Dimension | 5000mm×2500mm×1400mm |

Gallery

Scan QR to Read

Links:https://www.globefindpro.com/products/11190.html

Links:https://www.globefindpro.com/products/11190.html

Recommended Products

-

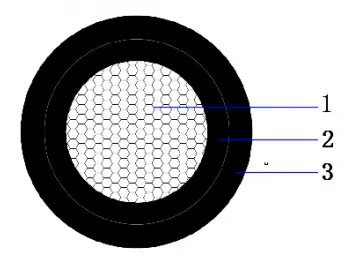

PV1-F solar cable

PV1-F solar cable

-

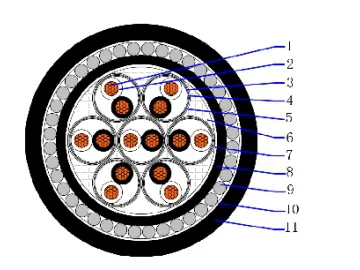

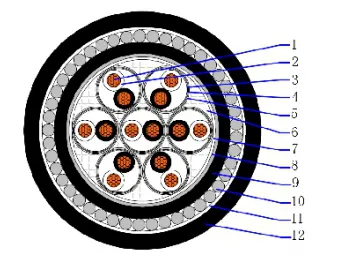

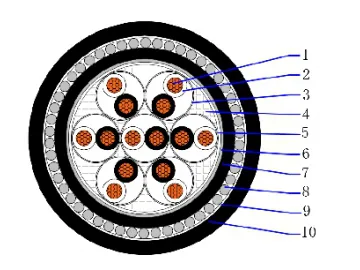

CU/PE/IS/PVC/SWA/PVC 500V PE insulated individual screen amoured instrumentation cable

CU/PE/IS/PVC/SWA/PVC 500V PE insulated individual screen amoured instrumentation cable

-

Embossing

Embossing

-

Reciprocator Spray Coater

Reciprocator Spray Coater

-

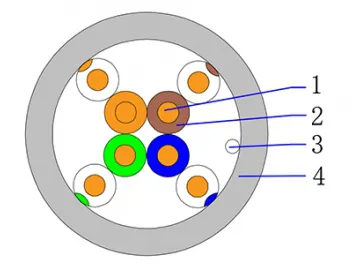

UTP CAT5E

UTP CAT5E

-

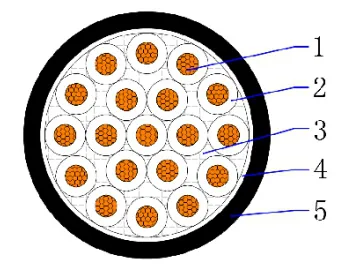

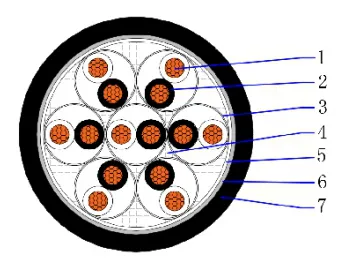

CU/PVC/PVC 0.6/1kV unarmoured control cable

CU/PVC/PVC 0.6/1kV unarmoured control cable

-

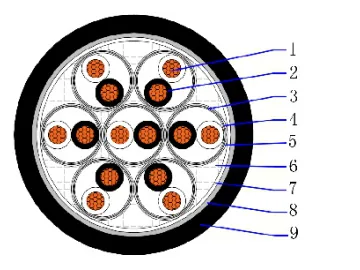

CU/PVC/ISOS/PVC/SWA/PVC 500V PVC insulated individual & overall screen amoured instrumentation cable

CU/PVC/ISOS/PVC/SWA/PVC 500V PVC insulated individual & overall screen amoured instrumentation cable

-

CU/PE/OS/PVC 500V PE insulated overall screen instrumentation cable

CU/PE/OS/PVC 500V PE insulated overall screen instrumentation cable

-

Wood Grain Printing

Wood Grain Printing

-

Vacuum Spray Coating Machine

Vacuum Spray Coating Machine

-

CU/PVC/ISOS/PVC 500V PVC insulated individual & overall screen instrumentation cable

CU/PVC/ISOS/PVC 500V PVC insulated individual & overall screen instrumentation cable

-

CU/PE/OS/PVC/SWA/PVC 500V PE insulated overall screen amoured instrumentation cable

CU/PE/OS/PVC/SWA/PVC 500V PE insulated overall screen amoured instrumentation cable

Hot Products