Embossing

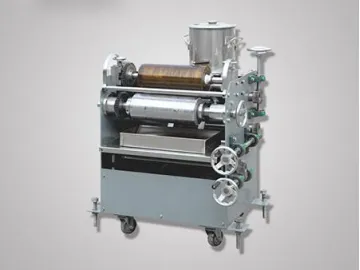

Function The embossing machine is designed to emboss a stereo and delicate wood grain pattern on the substrate. XMF can provide single side embossing machine and multi-side embossing machine. A customized embossing machine is available according to the width of your substrate. If you need to emboss different patterns, you only need to replace the pattern roller which can be also customized in XMF. Application  Available models Three color wood grain printing machine

Available models Three color wood grain printing machine

Multi-side embossing machine

The embossing machine is appropriate for the flat substrate embossing or multi-side embossing of wood, synthetic board and other materials.

Features The embossing machine is equipped with an IR digital read-out controller. In order to emboss an ideal pattern, the temperature of the pattern roller can be manually adjusted according to the substrate material and pattern characteristics. An automatic constant temperature control device is configured to keep the pattern roller maintaining a set temperature while running, which allows to obtain a consistent pattern and save the cost of power consumption. 50mm-thick heavy duty welded steel lifting frame of the embossing equipment ensures the running stability of the embossing roller and clear embossing effects. 40mm-thick seamless steel tube is adopted to make the embossing roller, which features higher stability and longer service life. Working principleThe pattern which customer needs are engraved on the pattern roller. After adjusting the distance between the pattern roller and the substrate, due to the large pressure of the pattern roller, it will emboss a stereo grain on the substrate. A built-in heating device can heat the pattern roller to 400 ℃ and the heated embossing pattern is more fixed and unchangeable.

Available in one single side embossing at a time.

Parameter| Voltage | AC 380V three-phase four-wire |

| Frequency | 50HZ |

| Total power | 18KW |

| Working width | 0-1320mm |

| Working thickness | 2-80mm |

| Minimum working length | 300mm |

| Feeding speed | 0-20m/min |

| Dimension | 1200mm×2200mm×1500mm |

Multi-side embossing machine

Available in multi-side embossing at a time. Up to four side.

Parameter| Voltage | AC three-phase four-wire380V |

| Frequency | 50HZ |

| Total power | 18KW |

| Working width | 0-120mm |

| Working thickness | 2-80mm |

| Minimum working length | 300mm |

| Feeding speed | 0-20m/min |

| Dimension | 1200mm×2200mm×1500mm |

Scan QR to Read

Links:https://www.globefindpro.com/products/11193.html

Links:https://www.globefindpro.com/products/11193.html

Recommended Products

-

Reciprocator Spray Coater

Reciprocator Spray Coater

-

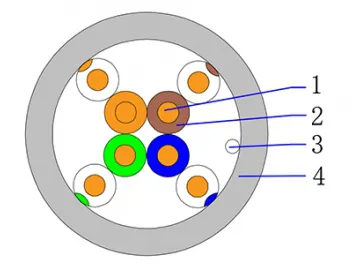

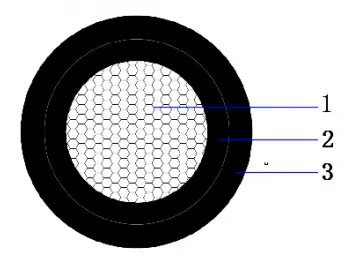

UTP CAT5E

UTP CAT5E

-

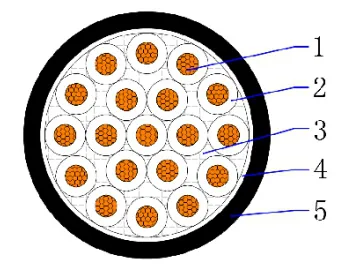

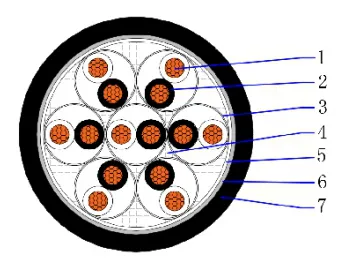

CU/PVC/PVC 0.6/1kV unarmoured control cable

CU/PVC/PVC 0.6/1kV unarmoured control cable

-

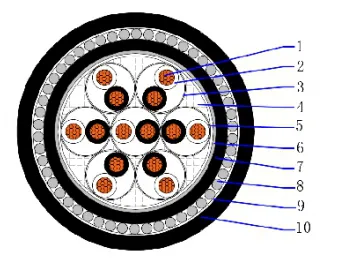

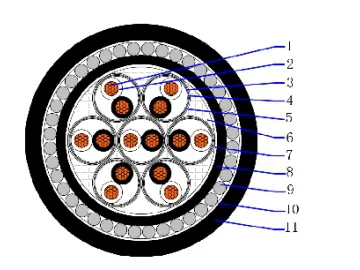

CU/PVC/OS/PVC/SWA/PVC 500V PVC insulated overall screen amoured instrumentation cable

CU/PVC/OS/PVC/SWA/PVC 500V PVC insulated overall screen amoured instrumentation cable

-

AL/XLPE/PVC/SWA/PVC 0.6/1kV Multicore armored cable

AL/XLPE/PVC/SWA/PVC 0.6/1kV Multicore armored cable

-

CU/PVC/CTS/PVC 0.6/1kV Copper tape screen control cable

CU/PVC/CTS/PVC 0.6/1kV Copper tape screen control cable

-

CU/PE/IS/PVC/SWA/PVC 500V PE insulated individual screen amoured instrumentation cable

CU/PE/IS/PVC/SWA/PVC 500V PE insulated individual screen amoured instrumentation cable

-

PV1-F solar cable

PV1-F solar cable

-

Curtain Coating

Curtain Coating

-

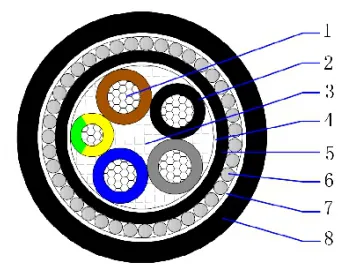

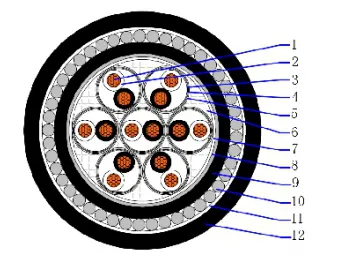

CU/PVC/ISOS/PVC/SWA/PVC 500V PVC insulated individual & overall screen amoured instrumentation cable

CU/PVC/ISOS/PVC/SWA/PVC 500V PVC insulated individual & overall screen amoured instrumentation cable

-

CU/PE/OS/PVC 500V PE insulated overall screen instrumentation cable

CU/PE/OS/PVC 500V PE insulated overall screen instrumentation cable

-

Wood Grain Printing

Wood Grain Printing

Hot Products