Indirect Extrusion

Indirect extrusion (backward extrusion) is one of the keystone technologies used by GoldEx. We have invested heavily into these systems and now have four indirect extrusion production lines in our workshop. They are equipped with a gas injection fast preheating furnace, hot skinning machine, continuous infrared temperature measurement system, water and gas combined quench, etc. Using this equipment, and we are able to extrude 17 tons materials per day.

Scan QR to Read

Links:https://www.globefindpro.com/products/11363.html

Links:https://www.globefindpro.com/products/11363.html

Recommended Products

-

Bonded Nylon Sewing Thread Supply for Clothing Company in Los Angeles

Bonded Nylon Sewing Thread Supply for Clothing Company in Los Angeles

-

Our Work

Our Work

-

Custom Printed Gusset Bags

Custom Printed Gusset Bags

-

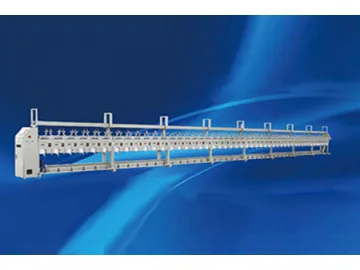

Vertical Soft Winder, Dye Package Winder

Vertical Soft Winder, Dye Package Winder

-

CO-50J Precision Rewinding Machine (Dye Packaging Winding, Hank to Cone)

CO-50J Precision Rewinding Machine (Dye Packaging Winding, Hank to Cone)

-

Optics

Optics

-

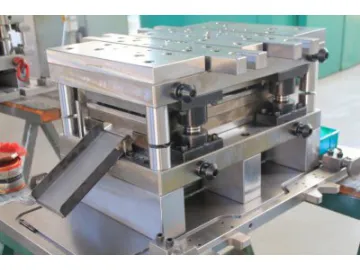

Tool Making

Tool Making

-

Extruded Aluminum Tubing, Drawn Seamless Aluminum Tubing

Extruded Aluminum Tubing, Drawn Seamless Aluminum Tubing

-

COTW Semi-automatic Shoelace Tipping Machine

COTW Semi-automatic Shoelace Tipping Machine

-

COS Heavy Narrow Fabric Needle Loom, Industrial Webbing Equipment

COS Heavy Narrow Fabric Needle Loom, Industrial Webbing Equipment

-

Metal Aglet

Metal Aglet

-

Semi-Automatic Shoelace Tipping Machine for Metal

Semi-Automatic Shoelace Tipping Machine for Metal

Hot Products