Capability

With over 100 production workers, large scale production is carried out with ease in our factory. The annual stainless steel product output of our facility is around 3 million units on average. This capacity allows us to supply products with on-time delivery at a competitive price.

Main processing equipment: lathe, hydraulic press, leak detector, argon arc welder, vacuuming machine, and printer, just to name a few.

Stainless tube

Welding

Vacuum

Vacuum test

Paint

Electrolysis

Polish

Seconddary detection

Laser printing

Crack paint

Packing

Quality Control

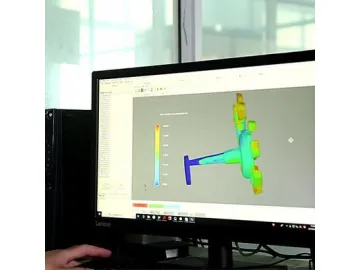

We have implemented a complete quality management system to control the quality of raw materials, production processes and finished products.

Raw MaterialThe quality assurance of raw material is extremely important to guarantee high quality finished products. Stainless steel raw materials will be strictly inspected by our experienced QC employees according to GB/T 29606-2013 standards.

Plan-Do-Check-Action, or PDCA circulation is used in our quality management process to control the quality of each phase of production and greatly improve the overall end result of our products.

Some of the testing items are listed as below:Appearance Printing and coating Heavy metals: lead, chrome, nickel, arsenic, etc. Finished Products

After production, random quality inspections will be performed on the finished products. The pass rate can reach greater than 99%.

All quality inspection reports are offered by a third party with CNAS and CMA qualification.

Links:https://www.globefindpro.com/products/11483.html

-

Thermal Conductive Absorber Pad

Thermal Conductive Absorber Pad

-

Home Appliances

Home Appliances

-

Electrical Device Parts

Electrical Device Parts

-

Capability

Capability

-

Medical Device Parts

Medical Device Parts

-

Containerized Seawater Desalination System

Containerized Seawater Desalination System

-

Datacom Infrastructure

Datacom Infrastructure

-

Two-part Thermal Gap Fillers, Thermal Gap Filling Gel

Two-part Thermal Gap Fillers, Thermal Gap Filling Gel

-

Phase Change Materials (PCMs)

Phase Change Materials (PCMs)

-

Equipment List

Equipment List

-

mobile-handheld

mobile-handheld

-

Non-Silicone Thermal Compounds

Non-Silicone Thermal Compounds