Capability

Capability

As a crucial element of the whole process, the die casting tooling plays a significant role in the deformation. Our die cast molds can achieve high accuracy and productivity, used over and over again. We use popular hardened tool steels in the market, such as SKD61 or H13, to ensure strong durability.Experienced designers take advantage of Modeflow and FEMA(Failure Mode and Effect Analysis) for the preliminary design and validation of die cast molds. Take potential factors affecting the product quality into consideration and eliminate possible problems in advance.

The metal part made by die casting usually have a rough surface which cannot be used directly for customers. We are capable of various processing methods to solve these problems properly, such as drilling, tapping or numerical control machining. Machining can remove round edges and loose flash of die castings. Different die cast parts need different machining services. Equipped with advanced CNC machines, we can produce the complex parts with better dimensional accuracy and consistency.

In addition to die casting tooling and machining, surface finishing is an essential procedure for optimizing appearance and performance, such as added corrosion resistance and wear. For metal casting, there are some common processing methods like grinding, sandblasting, powder coating, plating and buffing. Here are some recommended surface finishing services in our company:

We have committed to offering one-stop die casting service for many years. There are an extensive variety of our advanced equipment in our company. For example, die casting machines, CNC lathes and aluminum melting furnaces are beneficial to production, when spectrometers, hardness testers and cyclic corrosion testers are used for quality control. Considerable experience and professional knowledge of die casting help us to operate these machines smoothly with high efficiency.

As a crucial element of the whole process, the die casting tooling plays a significant role in the deformation. Our die cast molds can achieve high accuracy and productivity, used over and over again. We use popular hardened tool steels in the market, such as SKD61 or H13, to ensure strong durability.Experienced designers take advantage of Modeflow and FEMA(Failure Mode and Effect Analysis) for the preliminary design and validation of die cast molds. Take potential factors affecting the product quality into consideration and eliminate possible problems in advance.

The metal part made by die casting usually have a rough surface which cannot be used directly for customers. We are capable of various processing methods to solve these problems properly, such as drilling, tapping or numerical control machining. Machining can remove round edges and loose flash of die castings. Different die cast parts need different machining services. Equipped with advanced CNC machines, we can produce the complex parts with better dimensional accuracy and consistency.

In addition to die casting tooling and machining, surface finishing is an essential procedure for optimizing appearance and performance, such as added corrosion resistance and wear. For metal casting, there are some common processing methods like grinding, sandblasting, powder coating, plating and buffing. Here are some recommended surface finishing services in our company:

We have committed to offering one-stop die casting service for many years. There are an extensive variety of our advanced equipment in our company. For example, die casting machines, CNC lathes and aluminum melting furnaces are beneficial to production, when spectrometers, hardness testers and cyclic corrosion testers are used for quality control. Considerable experience and professional knowledge of die casting help us to operate these machines smoothly with high efficiency.

Scan QR to Read

Links:https://www.globefindpro.com/products/11487.html

Links:https://www.globefindpro.com/products/11487.html

Recommended Products

-

Medical Device Parts

Medical Device Parts

-

Containerized Seawater Desalination System

Containerized Seawater Desalination System

-

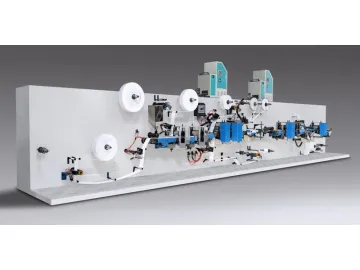

RL-RD-200, Production Line for Nursing Pad

RL-RD-200, Production Line for Nursing Pad

-

Seawater Desalination Plant in Iran Offshore Oil Platform

Seawater Desalination Plant in Iran Offshore Oil Platform

-

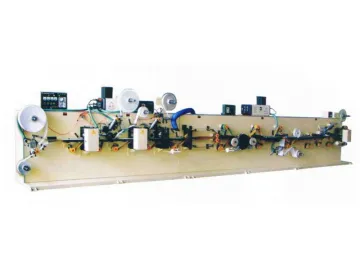

RL-HLD-150, Production Line for Disposable Underpads

RL-HLD-150, Production Line for Disposable Underpads

-

RL-HD-300, Production Line for Panty Liner

RL-HD-300, Production Line for Panty Liner

-

Electrical Device Parts

Electrical Device Parts

-

Home Appliances

Home Appliances

-

Thermal Conductive Absorber Pad

Thermal Conductive Absorber Pad

-

Capability

Capability

-

Datacom Infrastructure

Datacom Infrastructure

-

Two-part Thermal Gap Fillers, Thermal Gap Filling Gel

Two-part Thermal Gap Fillers, Thermal Gap Filling Gel