Alloy Steel Castings Cutting Tools

Add appropriate alloying elements into cast iron and cast steel, and you make alloy cast iron or alloy cast steel. Alloy elements cause changes in the matrix structure of cast iron or steel, and gives the new material an excellent heat resistance, abrasion resistance, low temperature resistance, no magnetism, and other advantageous characteristics. This makes alloy materials ideal for use in the production of rolls, slurry pumps, mining machines and other industries. When cutting these two materials, a PCBN cutting insert must have a high PCBN content. Cutting inserts we have produced for cutting alloy materials feature a PCBN content of 89-91%, thus meeting the cutting requirements for alloy cast iron and alloy cast steel.

DNMN/DNGN PCBN Inserts

(55° Diamond PCBN Inserts BNS-25 Series Cutting Tool) Parameters of DNMN/DNGN PCBN inserts

| TYPE | CORNER RADIUS | PCBN Content | PCBN Grain Size | Cutting Edge Length | Recommended Application | |||||||

| 02 | 04 | 06 | 08 | 10 | 12 | 16 | 20 | |||||

| DNM(G)N0903 | √ | √ | √ | √ | 89%-91% | 30μm-40μm | custom made | cast alloy steel | ||||

| DNM(G)N0904 | √ | √ | √ | √ | ||||||||

| DNM(G)N1104 | √ | √ | √ | √ | √ | √ | ||||||

| DNM(G)N1504 | √ | √ | √ | √ | √ | |||||||

| DNM(G)N1506 | √ | √ | √ | √ | √ | √ | √ | |||||

VNMN/VNGN PCBN Inserts

(35° Diamond PCBN Inserts BNS-25 Series Cutting Tool) Parameters of VNMN/VNGN PCBN inserts

| TYPE | CORNER RADIUS | PCBN Content | PCBN Grain Size | Cutting Edge Length | Recommended Application | |||||||

| 02 | 04 | 06 | 08 | 10 | 12 | 16 | 20 | |||||

| VNM(G)N0903 | √ | √ | √ | √ | 89%-91% | 30μm-40μm | custom made | cast alloy steel | ||||

| VNM(G)N0904 | √ | √ | √ | √ | ||||||||

| VNM(G)N1204 | √ | √ | √ | √ | √ | √ | ||||||

| VNM(G)N1207 | √ | √ | √ | √ | √ | |||||||

| VNM(G)N1504 | √ | √ | √ | √ | √ | √ | √ | |||||

WNMN/WNGN PCBN Inserts

(80° Triangular PCBN Inserts BNS-25 Series Cutting Tool) Parameters of WNMN/WNGN PCBN inserts

| TYPE | CORNER RADIUS | PCBN Content | PCBN Grain Size | Cutting Edge Length | Recommended Application | |||||||

| 02 | 04 | 06 | 08 | 10 | 12 | 16 | 20 | |||||

| WNM(G)N0603 | √ | √ | √ | √ | 89%-91% | 30μm-40μm | custom made | cast alloy steel | ||||

| WNM(G)N0604 | √ | √ | √ | √ | ||||||||

| WNM(G)N0803 | √ | √ | √ | √ | √ | |||||||

| WNM(G)N0804 | √ | √ | √ | √ | √ | |||||||

DNMA/DNGA PCBN Tipped Inserts

(55° Diamond Inserts BNW-25 Series CNC Cutting Tool) Parameters of DNMA/DNGA PCBN Tipped Inserts

| TYPE | Corner radius | PCBN Content | PCBN Grain Size | Cutting Edge Length | Recommended Application | |||||||

| 02 | 04 | 06 | 08 | 10 | 12 | 16 | 20 | |||||

| DNM(G)A1104 | √ | √ | √ | √ | √ | √ | 89%-91% | 30µm-40µm | custom made | cast alloy steel | ||

| DNM(G)A1504 | √ | √ | √ | √ | √ | √ | √ | √ | ||||

VNMA/VNGA PCBN Tipped Inserts

( 35° Diamond Inserts BNW-25 Series CNC Cutting Tool) Parameters of VNMA/VNGA PCBN Tipped Inserts

| TYPE | Corner radius | PCBN Content | PCBN Grain Size | Cutting Edge Length | Recommended Application | |||||||

| 02 | 04 | 06 | 08 | 10 | 12 | 16 | 20 | |||||

| VNM(G)A1604 | √ | √ | √ | √ | √ | √ | 89%-91% | 30µm-40µm | custom made | cast alloy steel | ||

SNMA/SNGA PCBN Tipped Inserts

( Square Inserts BNW-25 Series CNC Lathe Cutting Tool) Parameters of SNMA/SNGA PCBN Tipped Inserts

| TYPE | Corner radius | PCBN Content | PCBN Grain Size | Cutting Edge Length | Recommended Application | |||||||

| 02 | 04 | 06 | 08 | 10 | 12 | 16 | 20 | |||||

| SNM(G)A1204 | √ | √ | √ | √ | √ | √ | 89%-91% | 30µm-40µm | custom made | cast alloy steel | ||

Please contact us with any special requirements you have for alloy cast iron and alloy cast steel cutting. Backed by years of experience, we will offer the right PCBN insert for your needs.

Links:https://www.globefindpro.com/products/11943.html

-

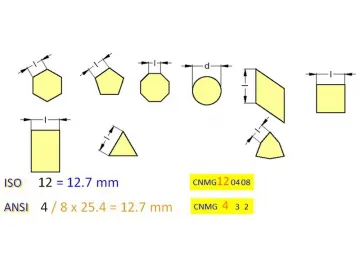

Turning insert Size

Turning insert Size

-

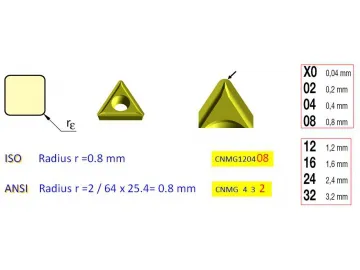

Turning insert Corner Radius

Turning insert Corner Radius

-

Hard Steel Cutting Tools

Hard Steel Cutting Tools

-

Window Advertising Display

Window Advertising Display

-

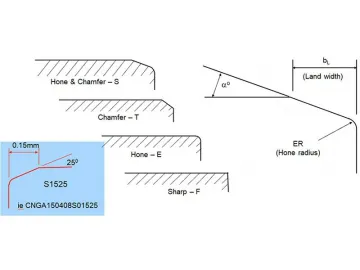

Turning insert Cutting Edge

Turning insert Cutting Edge

-

35 Degree Turning insert

35 Degree Turning insert

-

Round Turning insert

Round Turning insert

-

Wall Advertising Display

Wall Advertising Display

-

Flip Cover Slim PU Leather Card Slot Phone Case For iPhone X

Flip Cover Slim PU Leather Card Slot Phone Case For iPhone X

-

Triangle Turing insert

Triangle Turing insert

-

80 Degree Turning insert

80 Degree Turning insert

-

Glitter Fabric Shockproof Wallet Phone Case for LG K8 2017

Glitter Fabric Shockproof Wallet Phone Case for LG K8 2017