LW2000 ERW Tube Mill, 500x500mm

Directly Forming to Square, Rectangular Tube

Advantages

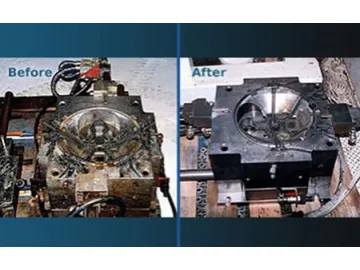

This tube mill directly forms square and rectangular tubes with a smaller inner arc radius, flatter brim, and overall better appearance compared to traditional methods for square forming from round tubes. The whole line features a low load, particularly in the sizing unit. 2.4-3% material is saved by directly forming when compared to traditional methods of square or rectangular forming from round tubes. It uses a multi-point bending method to reduce the forming steps, axial force, and side abrasion is bending step by step. It also saves power consumption and roller abrasion in order to ensure a higher product quality. It uses a combination roller which can produce square & rectangular tubes in a variety of different specifications. This significantly reduces the roller backup requirements and costs by almost 80%. The equipment is easy to adjust and requires no roller replacement for different specifications. The production line is automatically controlled, which significantly reduces the roller changing time, reduces labor, and improves production efficiency.

Production Procedures

Basic Technical Parameters

Basic Technical Parameters

Model List

The square or rectangular shaping is formed before the welding process, with significant advantages in terms of saving both energy and material costs.

Advantages

This tube mill directly forms square and rectangular tubes with a smaller inner arc radius, flatter brim, and overall better appearance compared to traditional methods for square forming from round tubes. The whole line features a low load, particularly in the sizing unit. 2.4-3% material is saved by directly forming when compared to traditional methods of square or rectangular forming from round tubes. It uses a multi-point bending method to reduce the forming steps, axial force, and side abrasion is bending step by step. It also saves power consumption and roller abrasion in order to ensure a higher product quality. It uses a combination roller which can produce square & rectangular tubes in a variety of different specifications. This significantly reduces the roller backup requirements and costs by almost 80%. The equipment is easy to adjust and requires no roller replacement for different specifications. The production line is automatically controlled, which significantly reduces the roller changing time, reduces labor, and improves production efficiency.

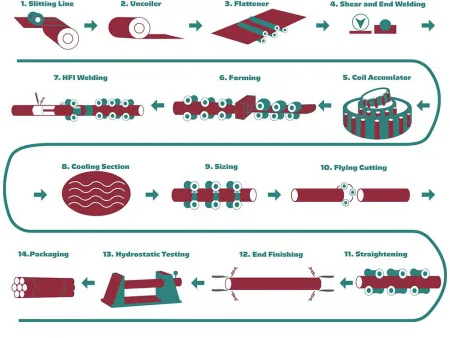

Production Procedures

Steel Coil → Uncoiling → Flattening/Leveling → Shear & End Cutting → Coil Accumulator → Forming → Welding → Deburring → Water Coiling → Sizing → Straightening → Cutting → Packaging

| ITEM | SPECIFICATIONS |

| Square Tube | 250 x 250 – 500 x 500 mm |

| Rectangular Tube | 300 x 200 – 600 x 400 mm |

| Wall Thickness | 8.0 mm – 20.0 mm |

| Tube Length | 6.0 m - 12.0 m |

| Line Speed | Max. 25 m/min |

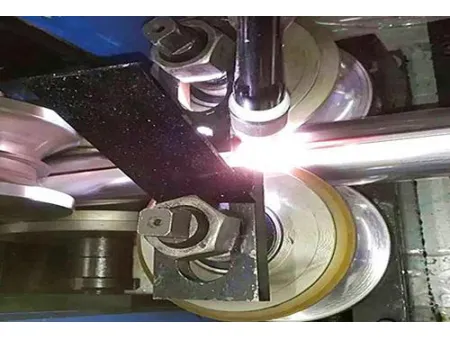

| Welding Method | Solid State High Frequency Welding |

| Forming Method | Directly Forming to Square and Rectangular Tubes |

Model List

| Model | Square Pipe (mm) | Rectangular Pipe (mm) | Thickness (mm) | Speed (m/min) |

| LW400 | 40×40~120×120 | 60×40~160×80 | 1.5~5.0 | 20~60 |

| LW600 | 50×50~150×150 | 70×50~200×100 | 2.0~6.0 | 20~50 |

| LW800 | 80×80~200×200 | 100×60~250×150 | 2.0~8.0 | 10~40 |

| LW1000 | 100×100~250×250 | 120×80~300×200 | 3.0~10.0 | 10~35 |

| LW1200 | 100×100~300×300 | 120×100~400×200 | 4.0~12.0 | 10~35 |

| LW1600 | 200×200~400×400 | 200×150~500×300 | 5.0~16.0 | 10~25 |

| LW2000 | 250×250~500×500 | 300×200~600×400 | 8.0~20.0 | 10~25 |

Scan QR to Read

Links:https://www.globefindpro.com/products/12246.html

Links:https://www.globefindpro.com/products/12246.html

Recommended Products