MS1325AC Series CNC Router/CNC Mill

CNC router is designed for high speed processing of flat workpiece. It uses 9KW spindle with automatically tool changer whose speed can be up to 24000r/min. It can finish various processes including carving, cutting, milling, and drilling.

Materials Cut

Soft metal and non-metallic materials including wood, PVC, particle board, fiberboard, insulation board, plywood, polystyrene, acrylic glass, polymethyl methacrylate, etc.

Applications

Furniture industry: for manufacturing panel furniture, office furniture, door, soft case, etc.

Woodwoking industry: loudspeaker box, cabinet, sewing machine table, musical instrument, etc.

Decoration industry: acrylic, plastic, MDF, polymethyl methacrylate, etc.

Features

The CNC router is equipped with row-type tool changer which can hold 6 to 12 tools (customizable). The tool changing only needs 4 seconds which can effectively improve the work efficiency.

Heavy-duty machine body

Automatic tool change spindle

Servo motor and reducer

The transmission is equipped with a linear guide rail, precision bevel wheel, and screw rod.

NK105G3 operating handle

Shaking lubrication system

Table

Parameters

| Model | F5-MS1325AC | F5-MS1631AC | F5-MS2131AC | F5-MS2142AC |

| Stroke | 1300×2500×300mm | 1600×3100×300mm | 2100×3100×300mm | 2100*4200*300mm |

| Shank diameter | Φ3.175-Φ18 | |||

| Weights | 1800KG | |||

| Package dimensions | 3700x2100x2100mm | |||

| Working voltage | AC380V-/220V | |||

9KW HSD tool change spindle, YASKAWA servo motor, and Syntec control system are all optional.

Users can request an added rotary axis.

Software such as Type3/Artcam/Mastercam/UG is optional.

Gallery

Scan QR to Read

Links:https://www.globefindpro.com/products/12296.html

Links:https://www.globefindpro.com/products/12296.html

Recommended Products

-

GM3015AH Series Extra-large CNC Cutting Machine

GM3015AH Series Extra-large CNC Cutting Machine

-

SGS1525/2040T-3S 3-axis Gantry CNC Machine

SGS1525/2040T-3S 3-axis Gantry CNC Machine

-

5-axis CNC Router, SG3565T-5S Series

5-axis CNC Router, SG3565T-5S Series

-

MS1325AD Series CNC Router/CNC Mill

MS1325AD Series CNC Router/CNC Mill

-

Nonwoven Fabric

Nonwoven Fabric

-

USB Port on Running Machine

USB Port on Running Machine

-

M1325AH2 Series CNC Router/CNC Mill

M1325AH2 Series CNC Router/CNC Mill

-

Activated Carbon

Activated Carbon

-

Melt Blown Polypropylene

Melt Blown Polypropylene

-

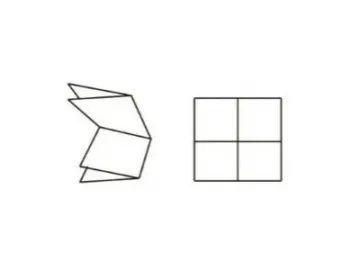

Paper and brochure folding types

Paper and brochure folding types

-

5-axis CNC Machining Center, SF-2040T-5S Series

5-axis CNC Machining Center, SF-2040T-5S Series

-

BS1325B Series 3 Axis Gantry CNC Router

BS1325B Series 3 Axis Gantry CNC Router