CNC Plasma Cutter-Metalworking

CNC plasma cutters are designed to cut sheet metals. They are a combination of a plasma cutter and digital control system with an excellent precision, efficiency and versatility, thereby providing an ideal alternative to traditional manual cutting.

Materials Cut

Various metal plates including steel plate, copper plate, iron plate, aluminum plate, galvanized sheet, titanium plate, and more

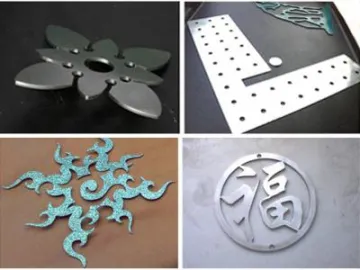

Applications

Advertising industry: manufacturing luminous characters, stainless steel business letters, signs and more

Furniture industry: manufacturing security doors, iron gates, stainless steel doors and more

Sheet metal industry: cutting iron plates, aluminum plates, galvanized sheets, white steel plates, titanium plates and more

Features

The machine body is seamlessly welded using thick walled squire steel after it has undergone a vibration aging treatment. This ensures no deformation, even after long-term use.

The jagged platform is specially designed for cutting metal materials.

This machine is equipped with an independent control cabinet with a high configuration, stable and easy operation. The arc ignition success rate is more than 99%.

The oil lubrication system lubricates parts to prevent rust. It is easy to use.

Parameters

| Model | F8-P1325 | F8-P1631 |

| Working area | 1300*2500*200mm | 1600*3100*200mm |

| Applicable Materials | iron plate, aluminum plate, galvanized sheet, white steel sheet, titanium plate, | |

| Control system | CC-S3C StatAI | |

| Processing thickness | 0.5mm-25mm | |

| Cutting Speed | 0-8000mm/min | |

| Working voltage | 3 phase 380V/220v | |

| Power frequency | 50HZ | |

| Cutting current | 60A/100A/120A | |

| File transfer method | USB ports | |

| Working mode | Non-touch pilot arc | |

A hypertherm plasma power source of 45A/65A/85A/105A is optional. Gallery

Scan QR to Read

Links:https://www.globefindpro.com/products/12309.html

Links:https://www.globefindpro.com/products/12309.html

Recommended Products

-

B1325B Series Gantry Moving CNC Router

B1325B Series Gantry Moving CNC Router

-

5-axis CNC Machine, SFD-1325A-5S Series

5-axis CNC Machine, SFD-1325A-5S Series

-

4 Axis CNC Router, MS1325AC4 Series

4 Axis CNC Router, MS1325AC4 Series

-

Large Format Paper Folding

Large Format Paper Folding

-

M1325AS3 Series CNC Router/CNC Mill

M1325AS3 Series CNC Router/CNC Mill

-

M1325AS3 Series CNC Router/CNC Mill

M1325AS3 Series CNC Router/CNC Mill

-

Fiberglass

Fiberglass

-

M1325AS4 Series CNC Router/CNC Mill

M1325AS4 Series CNC Router/CNC Mill

-

KS2030K8 Series CNC Router/CNC Mill

KS2030K8 Series CNC Router/CNC Mill

-

Gantry Moving 4 Axis CNC Router, SF2040Q-4S Series

Gantry Moving 4 Axis CNC Router, SF2040Q-4S Series

-

Filter Materials

Filter Materials

-

MS2030BH12 Series CNC Router/CNC Mill

MS2030BH12 Series CNC Router/CNC Mill

Hot Products