Materials

We use iron powder, stainless steel powder, alloy powder and Hoganas metal powder as raw materials. Due to the high purity and good compressibility of raw materials, our powder metallurgy processing parts have higher strength and better abrasion resistance, as well as better stability of size and appearance. Moreover, we have a large stock of materials and trusted suppliers, laying a good foundation for high productivity.

Iron-based material

Material composition: Fe, C

| Metal Grades | Tensile Property | Density | ||

| Ultimate Strength | Yield Strength (0. 2%) | Elongation (25. 4mm) | ||

| MPa | MPa | % | g/cm3 | |

| F-0000-10 | 120 | 90 | 1.5 | 6.1 |

| F-0000-15 | 170 | 120 | 2.5 | 6.7 |

| F-0000-20 | 260 | 170 | 7.0 | 7.3 |

| F-0005-10 | 170 | 120 | <1 | 6.1 |

| F-0005-20 | 220 | 160 | 1.0 | 6.6 |

| F-0005-25 | 260 | 190 | 1.5 | 6.9 |

| F-0005-50HT | 410 | (D) | <0.5 | 6.6 |

| F-0005-60HT | 480 | <0.5 | 6.8 | |

| F-0005-70HT | 550 | <0.5 | 7.0 | |

| F-0008-20 | 200 | 170 | <0.5 | 5.8 |

| F-0008-25 | 240 | 210 | <0.5 | 6.2 |

| F-0008-30 | 290 | 240 | <1.0 | 6.6 |

| F-0008-35 | 390 | 260 | 1.0 | 7.0 |

| F-0008-50HT | 450 | <0.5 | 6.3 | |

| F-0008-65HT | 520 | <0.5 | 6.6 | |

| F-0008-75HT | 590 | <0.5 | 6.9 | |

| F-0008-85HT | 660 | <0.5 | 7.1 | |

Material composition: Fe, Cu, C

| Metal Grades | Tensile Property | Density | ||

| Ultimate Strength | Yield Strength (0. 2%) | Elongation (25. 4mm) | ||

| MPa | MPa | % | g/cm3 | |

| FC-0200-15 | 170 | 140 | 1.0 | 6.0 |

| FC-0200-18 | 190 | 160 | 1.5 | 6.3 |

| FC-0200-21 | 210 | 180 | 1.5 | 6.6 |

| FC-0200-24 | 230 | 200 | 2.0 | 6.9 |

| FC-0205-30 | 240 | 240 | 6.0 | |

| FC-0205-35 | 280 | 280 | 6.3 | |

| FC-0205-40 | 340 | 310 | 6.7 | |

| FC-0205-45 | 410 | 340 | 7.1 | |

| FC-0205-60HT | 480 | 6.2 | ||

| FC-0205-70HT | 550 | 6.5 | ||

| FC-0205-80HT | 620 | (D) | 6.8 | |

| FC-0205-90HT | 690 | 7.0 | ||

| FC-0208-30 | 240 | 240 | 5.8 | |

| FC-0208-40 | 340 | 310 | 6.3 | |

| FC-0208-50 | 410 | 380 | 6.7 | |

| FC-0208-60 | 520 | 450 | 7.2 | |

| FC-0208-50HT | 450 | 6.1 | ||

| FC-0208-65HT | 520 | 6.4 | ||

| FC-0208-80HT | 620 | (D) | 6.8 | |

| FC-0208-95HT | 660 | 720 | 7.1 | |

| FC-0505-30 | 300 | 250 | 5.8 | |

| FC-0505-40 | 400 | 320 | 6.3 | |

| FC-0505-50 | 490 | 390 | 6.7 | |

| FC-0508-40 | 400 | 340 | 5.9 | |

| FC-0508-50 | 470 | 410 | 6.3 | |

| FC-0508-60 | 570 | 480 | 6.8 | |

| FC-0808-45 | 380 | 340 | 6.0 | |

| FC-1000-20 | 210 | 180 | 6.0 | |

Material composition: Fe, Cu, C, Ni

| Metal Grades | Tensile Property | Density | ||

| Ultimate Strength | Yield Strength (0. 2%) | Elongation (25. 4mm) | ||

| MPa | MPa | % | g/cm3 | |

| FN-0200-15 | 170 | 120 | 3.0 | 6.6 |

| FN-0200-20 | 240 | 170 | 5.0 | 7.0 |

| FN-0200-25 | 280 | 210 | 10.0 | 7.3 |

| FN-0205-20 | 280 | 170 | 1.5 | 6.6 |

| FN-0205-25 | 340 | 210 | 2.5 | 6.9 |

| FN-0205-30 | 410 | 240 | 4.0 | 7.2 |

| FN-0205-35 | 480 | 280 | 5.5 | 7.4 |

| FN-0205-80HT | 620 | 6.6 | ||

| FN-0205-105HT | 830 | 6.9 | ||

| FN-0205-130HT | 1000 | (D) | 7.1 | |

| FN-0205-155HT | 1100 | 7.2 | ||

| FN-0205-180HT | 1280 | 7.4 | ||

| FN-0208-30 | 310 | 240 | 1.5 | 6.7 |

| FN-0208-35 | 380 | 280 | 1.5 | 6.9 |

| FN-0208-40 | 480 | 310 | 2.0 | 7.1 |

| FN-0208-45 | 550 | 340 | 2.5 | 7.3 |

| FN-0208-50 | 620 | 380 | 3.0 | 7.4 |

| FN-0208-80HT | 620 | 6.7 | ||

| FN-0208-105HT | 630 | 6.9 | ||

| FN-0208-130HT | 1000 | (D) | 7.0 | |

| FN-0208-155HT | 1170 | 7.2 | ||

| FN-0208-180HT | 1340 | 7.4 | ||

| FN-0405-25 | 280 | 210 | 6.5 | |

| FN-0405-35 | 410 | 280 | 3.0 | 7.0 |

| FN-0405-45 | 620 | 340 | 4.5 | 7.4 |

| FN-0405-80HT | 590 | 6.5 | ||

| FN-0405-105HT | 760 | 6.8 | ||

| FN-0405-130HT | 930 | (D) | 7.0 | |

| FN-0405-155HT | 1100 | 7.3 | ||

| FN-0405-180HT | 1280 | 7.4 | ||

| FN-0408-34 | 310 | 280 | 1.0 | 6.5 |

| FN-0408-45 | 450 | 340 | 1.0 | 6.9 |

| FN-0408-55 | 550 | 410 | 1.0 | 7.2 |

Stainless steel material

| Metal Grades | Tensile Property | Density | ||

| Ultimate Strength | Yield Strength (0. 2%) | Elongation (25. 4mm) | ||

| MPa | MPa | % | g/cm3 | |

| SS-303L-12 | 270 | 120 | 17.5 | 6.6 |

| SS-303L-15 | 330 | 170 | 20.0 | 6.9 |

| SS-304L-13 | 300 | 120 | 23.0 | 6.6 |

| SS-303L-18 | 390 | 180 | 26.0 | 6.9 |

| SS-316L-15 | 280 | 140 | 18.5 | 6.6 |

| SS-316L-22 | 390 | 210 | 21.0 | 6.9 |

Scan QR to Read

Links:https://www.globefindpro.com/products/12358.html

Links:https://www.globefindpro.com/products/12358.html

Recommended Products

-

Aquatic Products Freezing System

Aquatic Products Freezing System

-

Building Construction

Building Construction

-

Furniture Making (hot melt adhesive for wood binding and edge binding)

Furniture Making (hot melt adhesive for wood binding and edge binding)

-

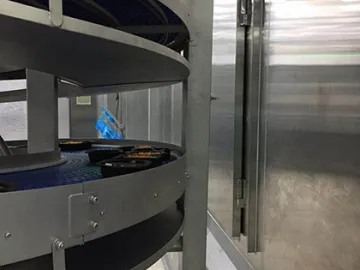

Prepared Meals Freezing System

Prepared Meals Freezing System

-

TRS Unit For Tank Container

TRS Unit For Tank Container

-

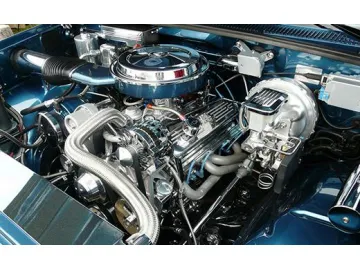

Automotive Industry (hot melt adhesive for automotive wire and filter)

Automotive Industry (hot melt adhesive for automotive wire and filter)

-

Automotive Repair and Maintenance

Automotive Repair and Maintenance

-

Convenient / Preserved Products Freezing System

Convenient / Preserved Products Freezing System

-

Zippers by Material

Zippers by Material

-

Heat Sink

Heat Sink

-

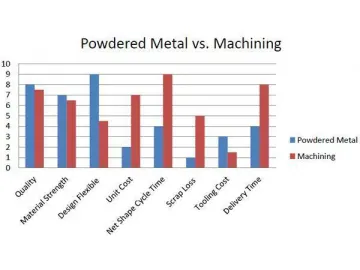

Advantage of PM process

Advantage of PM process

-

2# Zippers

2# Zippers