Piston Filling Line for Polyurethane Sealant Manufacturer

In 2010, a polyurethane sealant producer needed a fully automatic aluminum cartridge packaging machine to replace their costly manual step-by-step filling operation.

Problems of manual fillingTo produce such products, you need to carry out processes including filling, plunger inserting, desiccant adding, cartridge closing with aluminum cap and coding. This typically requires 6 people to cooperate. Moreover, safety accidents and quality problems are common in each process.

This client required reduced labor cost, reduced material loss and solving the quality safety problem in each process.

Based on the requirements of the customer, our technicians developed and produced an automatic horizontal piston filler (GRQY-3500-I) integrating automatic empty cartridge feeding, plunger feeding, filling, plunger inserting, desiccant adding, cartridge closing with cap and coding.

Its detailed functions and effects are as follows: Automatic filling: adopting volume metering mode, its efficiency is within ±2g/300ml. Automatic plunger inserting: using vacuumizing-first and capping-second method, no bubbles form during the operation. Automatic desiccant adding: this avoids human fatigue factor and the desiccant adding rate is 100% qualified. Automatic cartridge closing with aluminum cap: with mechanical arm assisted cartridge closing device, the sealing effect satisfied the customer’s requirements. The reject rate is no more than 3‰. Automatic coding is stable, having clear and uniform prints. Customer feedbackNow the equipment runs stably with 2 operators reduced from 6. With greatly improved safety factor, no accidents occurred. And the product quality was under control, without undesirable phenomenon like packaging disorder, etc. After running for 3 months, this customer replaced all filling machines with our automatic piston fillers.

Links:https://www.globefindpro.com/products/12547.html

-

FOB Price List

FOB Price List

-

Russian Mayor Victor came for environmental test chamber

Russian Mayor Victor came for environmental test chamber

-

400T Automotive Die Spotting Press

400T Automotive Die Spotting Press

-

Temperature and humidity testing chambers are delivered to overseas customers

Temperature and humidity testing chambers are delivered to overseas customers

-

Piston Filling System for Silicone Sealant Manufacturer

Piston Filling System for Silicone Sealant Manufacturer

-

Laboratory Testing

Laboratory Testing

-

Molds Manufacture

Molds Manufacture

-

Raw Materials

Raw Materials

-

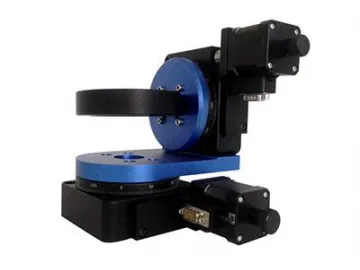

WN202RA100M Dual-Axis Motorized Rotation Stages

WN202RA100M Dual-Axis Motorized Rotation Stages

-

13mm Travel Precision Translation Stages

13mm Travel Precision Translation Stages

-

Wood Coating

Wood Coating

-

WN03RA250S Motorized Rotation Stages with Steeper Motor

WN03RA250S Motorized Rotation Stages with Steeper Motor