Facilities

Asia America operates with several 4 axis CNC turning and 5 axis CNC machining centers. The highly effiicent and highly precise multi-axis machining turning and milling machine can minimize machine adjusting processes and shorten production process. It allows improvements on productivity and reduce production costs. While, the multi-axis machining turning and milling machines features better flexibile machining capabilities suitable for work pieces that requires complex machining processes and higher precision requirements. The production equipment of Asia America can satisfy the order requirements of many customers.

| ITEM | Description | Qty | Model | Vendor | Size | Accuracy |

| 1 | CNC MILLING CENTER | 5 | FV56T-APC | YCM | 3 axis (500*400*450) | 0.01mm |

| 2 | CNC MILLING CENTER | 22 | SR3 | AKIRA-SEIKI | 4 axis (762*400*450) | 0.01mm |

| 3 | CNC MILLING CENTER | 2 | V5A | AKIRA-SEIKI | 4 axis (1300*550*550) | 0.01mm |

| 4 | CNC MILLING CENTER | 4 | V4A | AKIRA-SEIKI | 3 axis (1000*500*500) | 0.01mm |

| 5 | CNC MILLING CENTER | 2 | V3A | AKIRA-SEIKI | 3 axis (800*500*500) | 0.01mm |

| 6 | CNC MILLING CENTER | 5 | Mini-MZL | HAAS(AMERICA) | 3 axis (400*300*250) | 0.01mm |

| 7 | CNC MILLING CENTER | 8 | V640 | SUNS | 5 axis (600*400*300) | 0.01mm |

| 8 | CNC LATHE | 10 | STS-46 | SHENTESI | Slant (Φ250*350L) | 0.01mm |

| 9 | CNC LATHE | 10 | ST-52M | XINSHUO | 8 position turret+Y axis living tool (Φ190*370L) | 0.01mm |

| 10 | CNC LATHE | 4 | DL-20M | DALIAN LATHE | 12 position turret (Φ400*1000L) | 0.01mm |

| 11 | CNC LATHE | 1 | SLC-20 | AKIRA-SEIKI | 12 position C axis turret living tool (Φ250*350L) | 0.01mm |

| 12 | CNC SWISS-STYLE LATHE | 8 | ST-32MB | XINSHUO | (back spindle) 5 axis swiss-style lathe (Φ300*300L) | 0.01mm |

| 13 | Surface Grinder | 3 | Surface Grinder | ZHONGQUAN/JIANDE | 1000*500*350 | 0.005mm |

| 14 | Surface Grinder | 1 | Surface Grinder | WILTON | 600*200*170 | 0.005mm |

Measuring facility list

Asia America has a Coordinate Measuring Machine (CMM), automatic optical imager, rockwell hardness tester and some other complete and advanced testing machines and equipments. These enable us to complete inspections, ensuring the highest quality standards .

| NO. | Name | Qty | Vendor | Specification | Measuring accuracy |

| 1 | Coordinate measuring machine (CMM) | 1 | Mitutoyo (Japan) | X:705mm Y:705mm Z:605mm | 3+2L/1000μm |

| 2 | Automatic imager | 1 | 3D Family | X:250mm Y:150mm Z:200mm | 0.001 |

| 3 | Imager | 1 | 3D Family | X400 Y300 Z300mm | 0.003mm |

| 4 | Automatic electronic altitude meter | 1 | TESA (Swiss) | 0~600 mm | 0.0018mm |

| 5 | Rockwell hardness tester | 1 | DeChuang | HRC: 0~100 HRB: 30~130 | 1.2HR |

| 6 | Leeb hardness tester | 1 | Meitai | HLD 170~960 | ± 6 HLD |

| 7 | Surface Rockwell hardness tester | 1 | Wolpert (America) | HRC: 0~100 HRB: 30~130 | 1.2HR |

| 8 | Surface roughometer | 1 | Mitutoyo (Japan) | Ra Rz Rq | 0.02μm |

| 9 | Film thickness tester | 1 | Time High | - | 0.004MM |

Links:https://www.globefindpro.com/products/12605.html

-

LOGO Meanings

LOGO Meanings

-

Aluminum Billet Sawing (Automatic Aluminum Saw)

Aluminum Billet Sawing (Automatic Aluminum Saw)

-

Aluminum Billet Stacker

Aluminum Billet Stacker

-

Medical Air Compressor

Medical Air Compressor

-

Geological Seismometer, Type DZQ6-2A

Geological Seismometer, Type DZQ6-2A

-

Intelligent Well Logging System

Intelligent Well Logging System

-

Precision Machined Components for OHLINS

Precision Machined Components for OHLINS

-

Melting and Casting Line

Melting and Casting Line

-

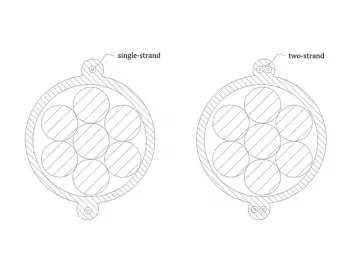

Prestressed Ground Anchor

Prestressed Ground Anchor

-

Aluminum Billet Pre-heat Furnace for Extrusion - Multi Billet

Aluminum Billet Pre-heat Furnace for Extrusion - Multi Billet

-

How can ground anchor be available in 100% recovery?

How can ground anchor be available in 100% recovery?

-

Wanhao bought stone cutting machine

Wanhao bought stone cutting machine