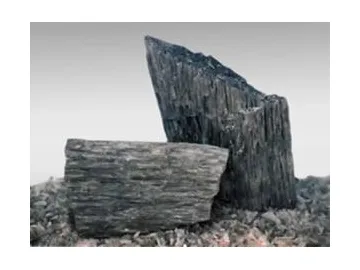

Green Silicon Carbide in Grits

Green silicon carbide grit is produced within internal resistance furnaces by mixing high purity silica sand and petroleum coke with high temperatures. The micro hardness of the material is 3200-3400 kg/mm2. The weak shape of the individual grains make it used extensively in vitrified, organic bonded abrasives for grinding of cemented carbide tools and also for the manufacture of resistance heating elements in a high temperature furnace as well as the ceramic lapping applications. This material is available in grit sizes, micron sizes, split sizes.

Availability

| GRIT SIZES | CHEMICAL SPECIFICATION | ||

| SiC | F. C. | Fe2O3 | |

| 12 - 90 # | 99.00 min. | 0.20 max. | 0.20 max. |

| 100 - 180 # | 98.00 min. | 0.25 max. | 0.50 max. |

| 220 - 240 # | 97.50 min. | 0.25 max. | 0.70 max. |

| W63 - W20 # | 97.00 min. | 0.30 max. | 0.70 max. |

| W14 - W10 # | 95.00 min. | 0.50 max. | 0.70 max. |

| W7 - W5 # | 94.00 min. | 0.50 max. | 0.70 max. |

| SPLIT SIZES | CHEMICAL SPECIFICATION | ||

| SiC | F. C. | Fe2O3 | |

| - 50 + 0 mm | 97.50 min. | 0.50 max. | 0.60 max. |

Scan QR to Read

Links:https://www.globefindpro.com/products/12986.html

Links:https://www.globefindpro.com/products/12986.html

Recommended Products

-

Depressed Center Grinding Wheels for Stainless Steels

Depressed Center Grinding Wheels for Stainless Steels

-

Laser Welded Diamond Saw Blades

Laser Welded Diamond Saw Blades

-

Silver Brazed Diamond Saw Blades

Silver Brazed Diamond Saw Blades

-

High Purity Fused Refractory Mullite

High Purity Fused Refractory Mullite

-

Flexible Depressed Center Grinding Wheels

Flexible Depressed Center Grinding Wheels

-

Purity Fused Magnesia Alumina Spinel

Purity Fused Magnesia Alumina Spinel

-

Cutting & Grinding Wheels for Non-Ferrous Metals

Cutting & Grinding Wheels for Non-Ferrous Metals

-

DIY Grade T.C.T Saw Blades

DIY Grade T.C.T Saw Blades

-

JAC-K456CT Cutting-Off Wheels for Concrete & Stones

JAC-K456CT Cutting-Off Wheels for Concrete & Stones

-

Hot Pressed Sintered Saw Blades

Hot Pressed Sintered Saw Blades

-

Cold Pressed Sintered Cup Wheels

Cold Pressed Sintered Cup Wheels

-

Refractory Fused Zirconia Mullite

Refractory Fused Zirconia Mullite

Hot Products