APA 15-260 Ton Precision Metal Stamping Press

Characteristic The APA 15-260 ton precision metal stamping press was developed and manufactured with a strong steel structure and welded using high quality steel plate. The metalworking machine tool features stable precision and reliability after eliminating the internal stress of the material. The transmission center and metalworking machine tool center are located in the same spot, so that the stamping press can optimize precision and stability. Two symmetrical balancers are used to ensure the stability of operation. The precision of die adjustment is as high as 0.1 mm, so the stamping machine can be operated safely and reliably. Parts like the bent axle, gear set, connecting rod, etc., are designed for high integrality and abrasive resistance following a hard-anodized and grinding process. Sensitive and reliable clutch/brake, excellent double solenoid valve and overload protector are used to ensure the precision and safety of the start and stopping of the slide.

Technical Specifications

Outline Dimension

Configuration

Capacity Curve Capacity Curve

Slide table

Bolster table

Factory

Technical Specifications

| Name | Model | APA-15 | |

| Type | Ton | Type V | |

| Capacity | 15 | ||

| Rated tonnage point | mm | 1 | |

| Stroke number per minute | Speed range | s.p.m | 120-180 |

| Stable speed | s.p.m | 130 | |

| Stroke | mm | 60 | |

| Die height | mm | 200 | |

| Slide adjustment | mm | 50 | |

| Slide area | mm | 300×220×50 | |

| Bolster area | mm | 680×300×70 | |

| Shank hole | mm | 38.1 | |

| Main motor | kw | 2.2 | |

| Slide adjust device | HP | Manual operation | |

| Air pressure | kg/cm2 | 6 | |

| Presses precision | GB(JIS) 1 class | ||

| Presses dimension | mm | 1236×830×1920 | |

| Presses weight | Ton | 1.8 | |

| Name | Model | APA-25A | |

| Type | Ton | Type V | |

| Capacity | 25 | ||

| Rated tonnage point | mm | 3.2 | |

| Stroke number per minute | Speed range | s.p.m | 60-140 |

| Stable speed | s.p.m | 110 | |

| Stroke | mm | 80 | |

| Die height | mm | 195 | |

| Slide adjustment | mm | 50 | |

| Slide area | mm | 300×220×50 | |

| Bolster area | mm | 680×300×70 | |

| Shank hole | mm | 38.1 | |

| Main motor | kw | 3.7 | |

| Slide adjust device | HP | Manual operation | |

| Air pressure | kg/cm2 | 6 | |

| Presses precision | GB(JIS) 1 class | ||

| Presses dimension | mm | 1280×850×2200 | |

| Presses weight | Ton | 2.1 | |

| Die cushion capacity | Ton | - | |

| Stroke of die cusion | mm | - | |

| Die cushion effective area | mm2 | - | |

| Name | Model | APA-25 | ||

| Type | Ton | Type V | Type H | |

| Capacity | 25 | |||

| Rated tonnage point | mm | 3.2 | 1.6 | |

| Stroke number per minute | Speed range | s.p.m | 60-140 | 130-200 |

| Stable speed | s.p.m | 110 | ||

| Stroke | mm | 70 | 30 | |

| Die height | mm | 195 | 215 | |

| Slide adjustment | mm | 50 | ||

| Slide area | mm | 300×220×50 | ||

| Bolster area | mm | 680×300×70 | ||

| Shank hole | mm | 38.1 | ||

| Main motor | kw | 3.7 | ||

| Slide adjust device | HP | Manual operation | ||

| Air pressure | kg/cm2 | 6 | ||

| Presses precision | GB(JIS) 1 class | |||

| Presses dimension | mm | 1280×850×2200 | ||

| Presses weight | Ton | 2.1 | ||

| Name | Model | APA-35 | ||

| Type | Ton | Type V | Type H | |

| Capacity | 35 | |||

| Rated tonnage point | mm | 3.2 | 1.6 | |

| Stroke number per minute | Speed range | s.p.m | 40-120 | 110-180 |

| Stable speed | s.p.m | 85 | ||

| Stroke | mm | 70 | 40 | |

| Die height | mm | 220 | 235 | |

| Slide adjustment | mm | 55 | ||

| Slide area | mm | 360×250×50 | ||

| Bolster area | mm | 800×400×70 | ||

| Shank hole | mm | 38.1 | ||

| Main motor | kw | 3.7 | ||

| Slide adjust device | HP | Manual operation | ||

| Air pressure | kg/cm2 | 6 | ||

| Presses precision | GB(JIS) 1 class | |||

| Presses dimension | mm | 1380×900×2400 | ||

| Presses weight | Ton | 3 | ||

| Die cushion capacity | Ton | 2.3 | ||

| Stroke of die cusion | mm | 50 | ||

| Die cushion effective area | mm2 | 300×230 | ||

| Name | Model | APA-45 | ||

| Type | Ton | Type V | Type H | |

| Capacity | 45 | |||

| Rated tonnage point | mm | 3.2 | 1.6 | |

| Stroke number per minute | Speed range | s.p.m | 40-100 | 100-150 |

| Stable speed | s.p.m | 75 | ||

| Stroke | mm | 80 | 50 | |

| Die height | mm | 250 | 265 | |

| Slide adjustment | mm | 60 | ||

| Slide area | mm | 400×300×60 | ||

| Bolster area | mm | 850×440×80 | ||

| Shank hole | mm | 38.1 | ||

| Main motor | kw | 5.5 | ||

| Slide adjust device | HP | Manual operation | ||

| Air pressure | kg/cm2 | 6 | ||

| Presses precision | GB(JIS) 1 class | |||

| Presses dimension | mm | 1600×950×2500 | ||

| Presses weight | Ton | 3.8 | ||

| Die cushion capacity | Ton | 2.3 | ||

| Stroke of die cusion | mm | 50 | ||

| Die cushion effective area | mm2 | 300×230 | ||

| Name | Type | APA-60 | APA-80 | APA-110 | APA-160 | APA-200 | APA-260 | |||||||

| Model | Ton | Type V | Type H | Type V | Type H | Type V | Type H | Type V | Type H | Type V | Type H | Type V | Type H | |

| Capacity | 60 | 80 | 110 | 160 | 200 | 260 | ||||||||

| Rated tonnage point | mm | 4 | 2 | 4 | 2 | 6 | 3 | 6 | 3 | 6 | 3 | 7 | 3.5 | |

| Stroke number per minute | Speed range | s.p.m | 35 - 90 | 80 - 120 | 35 - 80 | 80 - 120 | 30 - 60 | 60 - 90 | 20 - 50 | 40 - 70 | 20 - 50 | 50 - 70 | 20 - 40 | 40 - 50 |

| Stable speed | s.p.m | 65 | 65 | 50 | 35 | 35 | 30 | |||||||

| Stroke | mm | 120 | 60 | 150 | 70 | 180 | 80 | 200 | 90 | 200 | 100 | 250 | 150 | |

| Die height | mm | 310 | 340 | 340 | 380 | 360 | 410 | 460 | 510 | 460 | 510 | 500 | 550 | |

| Slide adjustment | mm | 75 | 80 | 80 | 100 | 110 | 120 | |||||||

| Slide area | mm | 500×360×70 | 560×420×70 | 650×470×80 | 700×550×90 | 850×630×90 | 950×700×100 | |||||||

| Bolster area | mm | 900×500×80 | 1000×550×90 | 1150×600×110 | 1250×800×140 | 1400×820×160 | 1500×840×180 | |||||||

| Shank hole | mm | 50 | 50 | 50 | 65 | 65 | 65 | |||||||

| Main motor | kw | 5.5 | 7.5 | 11 | 15 | 18 | 22 | |||||||

| Slide adjust device | HP | Manual operation | ||||||||||||

| Air pressure | kg/cm2 | 6 | 6 | 6 | 6 | 6 | 6 | |||||||

| Presses precision | GB(JIS) 1 class | GB(JIS) 1 class | GB(JIS) 1 class | GB(JIS) 1 class | GB(JIS) 1 class | GB(JIS) 1 class | ||||||||

| Presses dimension | mm | 1600×1000×2800 | 1800×1180×2800 | 1900×1300×3200 | 2300×1400×3800 | 2615×1690×4075 | 2780×1850×4470 | |||||||

| Presses weight | Ton | 5.6 | 6.5 | 9.6 | 16 | 23 | 32 | |||||||

| Die cushion capacity | Ton | 3.6 | 3.6 | 6.3 | 10 | 14 | 14 | |||||||

| Stroke | mm | 70 | 70 | 80 | 80 | 100 | 100 | |||||||

| Die cushion effective area | mm2 | 350×300 | 450×310 | 500×350 | 650×420 | 710×480 | 810×480 | |||||||

Outline Dimension

| Specification | APA-25 | APA-35 | APA-45 | APA-60 | APA-80 | APA-110A | APA-160 | APA-200 | APA-260 |

| A | 1100 | 1200 | 1400 | 1420 | 1595 | 1720 | 2140 | 1440 | 2605 |

| B | 840 | 900 | 950 | 1000 | 1170 | 1290 | 1390 | 1690 | 1850 |

| C | 2135 | 2345 | 2245 | 2780 | 2980 | 3195 | 3670 | 4075 | 4470 |

| D | 680 | 800 | 850 | 900 | 1000 | 1150 | 1250 | 1400 | 1500 |

| E | 300 | 400 | 440 | 500 | 550 | 600 | 800 | 820 | 840 |

| F | 470 | 520 | 560 | 700 | 770 | 910 | 990 | 1130 | 1130 |

| G | 250 | 285 | 340 | 400 | 420 | 470 | 550 | 630 | 700 |

| H | 800 | 790 | 800 | 795 | 840 | 840 | 910 | 1030 | 1030 |

| I | 260 | 290 | 320 | 420 | 480 | 530 | 650 | 650 | 750 |

| J | 444 | 488 | 502 | 526 | 534 | 616 | 660 | 790 | 900 |

| K | 160 | 205 | 225 | 255 | 280 | 305 | 405 | 415 | 430 |

| L | 980 | 1040 | 1170 | 1180 | 1310 | 1420 | 1760 | 2040 | 2005 |

| M | 700 | 800 | 810 | 890 | 980 | 1100 | 1200 | 1400 | 1560 |

| N | 540 | 620 | 670 | 720 | 780 | 920 | 1000 | 1160 | 1300 |

| O | 1275 | 1375 | 1575 | 1595 | 1770 | 1895 | 1895 | 2615 | 2780 |

| P | 278 | 278 | 313 | 333 | 448 | 488 | 545 | 593 | 688 |

| Q | 447 | 560 | 585 | 610 | 620 | 685 | 725 | 805 | 875 |

| R | 935 | 1073 | 1130 | 1378 | 1506 | 1650 | 1960 | 2188 | 2460 |

Configuration

| Standard | Optional |

| Hydraulic over-load protector | Inverter |

| Manual operation slide adjust device (TP below 60 ) | High performance wet clutch & brake |

| Slide adjust device (TP above 60 ) | Electrical automatic lubrication system |

| Mechanical die height indicator (TP below 60 ) | Pneumatic die cushion device |

| Electric die height indicator (TP above 60 ) | Foot switch |

| Balance device | Quick die change device (Die lifter, clamp and die arm) |

| Rotary cam switch | Slide knock-out device |

| Crank angle indicator | Misfeed detection consent |

| Electrical stroke counter | Power supply |

| Air source receptacle | Auto-vibration press mount |

| Against over-run safety device | Photo-electronic safety device |

| Blowing equipment | Die room light |

| Maintenance tool box | Touch pad counter system |

| Automatic feeding device (Feeder, Rack, Correction machine) | |

| Mechanism hand |

Capacity Curve Capacity Curve

Slide table

Bolster table

| Model | A | B | C | D | E | F | G | H | L | T type ditch |

| APA-15 | 240 | 120 | 90 | 300 | - | 150 | Φ38.1 | 80 | 220 | Ⅰ |

| APA-25A | 240 | 120 | 90 | 300 | - | 150 | Φ38.1 | 80 | 220 | Ⅰ |

| APA-25A | 240 | 120 | 90 | 300 | - | 150 | Φ38.1 | 80 | 220 | Ⅰ |

| APA-35 | 280 | 140 | 120 | 360 | - | 160 | Φ38.1 | 100 | 250 | Ⅰ |

| APA-45 | 300 | 150 | 120 | 400 | - | 210 | Φ38.1 | 120 | 300 | Ⅰ |

| APA-60 | 320 | 160 | 150 | 500 | 220 | 220 | Φ50 | 160 | 360 | Ⅱ |

| APA-80 | 360 | 180 | 150 | 560 | 300 | 220 | Φ50 | 180 | 420 | Ⅱ |

| APA-110 | 400 | 200 | 150 | 650 | 300 | 220 | Φ50 | 220 | 470 | Ⅱ |

| APA-160 | 440 | 220 | 160220 | 700 | 300 | 175 | Φ65 | 220 | 550 | Ⅱ |

| APA-200 | 480 | 240 | 280 | 850 | 420 | 200 | Φ65 | 300 | 630 | Ⅱ |

| APA-260 | 520 | 260 | 290 | 950 | 420 | 200 | Φ65 | 300 | 700 | Ⅱ |

Factory

Index

progressive die stamping, metal punching machine, power press

Scan QR to Read

Links:https://www.globefindpro.com/products/13428.html

Links:https://www.globefindpro.com/products/13428.html

Recommended Products

-

CNC Turret Punch Machine (Mechanical)

CNC Turret Punch Machine (Mechanical)

-

APD 80-260 Ton Precision Metal Stamping Press

APD 80-260 Ton Precision Metal Stamping Press

-

VSHS Series Hydraulic Guillotine Shear

VSHS Series Hydraulic Guillotine Shear

-

Royal Blue Masterbatch

Royal Blue Masterbatch

-

Iced Beverage Display Freezer

Iced Beverage Display Freezer

-

LYB series Gap Metal Lathe (Spindle Hole φ65mm)

LYB series Gap Metal Lathe (Spindle Hole φ65mm)

-

CC series Gap Metal Lathe (Spindle Hole φ52mm)

CC series Gap Metal Lathe (Spindle Hole φ52mm)

-

Brown Masterbatch

Brown Masterbatch

-

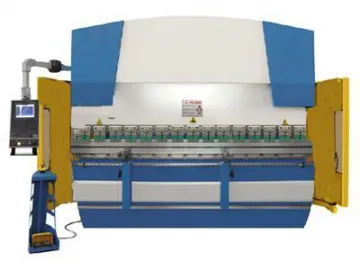

Sheet Metal Press Brake

Sheet Metal Press Brake

-

API 25-60 Ton High Speed Precision Metal Stamping Press

API 25-60 Ton High Speed Precision Metal Stamping Press

-

Raw Materials

Raw Materials

-

Sun Yellow Masterbatch

Sun Yellow Masterbatch

Hot Products