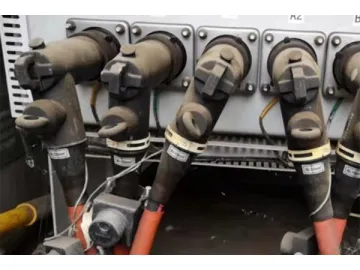

200A Loadbreak Elbow Connector

American 200A elbow connector is suitable for 200A electrical systems in the United States. It is widely used in American pad-mounted transformers, ring main units, cable branch boxes, underground transformers, and high-voltage electrical connections with other electrical equipment. Compatible jointing devices include single feed-thru bushing, dual feed-thru bushing, 200A interface for bus bar, 200A interface for etc. Product interfaces are in compliance with the design standard of 200A bushing in IEEE 386.

It offers fully insulating, sealing, and shielding solutions.

The well-compressed appliance guarantees the reliability of the application and more compact size compared to other configurations.

The testing point can be installed with a electriferous display or fault indicator to show the charged and fault status.

The conductive rod connector is equipped with arc extinguishing function as a load switch to conduct or cut 200A current, except for cutting current during a malfunction.

Design of the inner and external screens of the shielding-type plug optimizes the electric field structure and uniforms the exterior shielding layer, with grounding resistance of less than 5000Ω, so as to effectively keep the electric potential of the outer surface of the cable connector at zero to ensure the safety of the maintenance operator.

The cold shrink tubing compression sealing between the plug end and the cable prevents cable moisture intrusion. It meets the requirement of industrial IEEE 386-2006 standard.

| Voltage Class | 15kV | 24kV |

| Continuous Current | 200A | 200A |

| AC Withstand Voltage | 42kV/5min | 54kV/5min |

| Partial Discharge | 15kV, ≤ 10pC | 26.8kV, ≤ 10pC |

| Impulse Withstand Voltage (10 times for each polarity) | 95kV | 125kV |

| Switching Current | 14.4kV, 200A,10 times | 26.3kV, 200A, 10 times |

| Screen Resistance | 5000Ω | 5000Ω |

| Cable Cross Section | 25-120mm² | 25-120mm² |

15kV 200A Loadbreak Elbow Connector 25kV 200A Loadbreak Elbow Connector

Applications

The 25kV 200A loadbreak elbow connector is suitable for power systems at 25kV and below under American standards. It is used to connect cables and electrical equipment, such as ring main units, cable branch boxes, transformers, switchgear, etc., to achieve a fully insulated electrical connection between cables and equipment and build a ring network system.

Standard and Dimensions

It meets the requirements of IEEE386 in the Americas.

| Rated Voltage (U0/U) | 15.2/26.3kV |

| Continuous Current | 200A |

| AC Withstand Voltage | 40kV for 1min |

| Partial Discharge | 19kV,≤3pC |

| Impulse Withstand Voltage (10 times for each polarity) | 125kV |

| Switching Current | 26.3kV, 200A, 10 times |

| Screen Resistance | ≤5000Ω |

Made of high quality EPDM rubber material, the product can provide fully shielded separable connection when mated with proper epoxy bushing products. Besides, it enjoys excellent mechanical properties. OEM customized service is available such as laser printing of the client company name on the product surface. Fully tested and approved by the factory, the product is directly supplied by the factory to offer you the best performance at the lowest price. The shorter delivery period saves you time and energy.

Links:https://www.globefindpro.com/products/1365.html

-

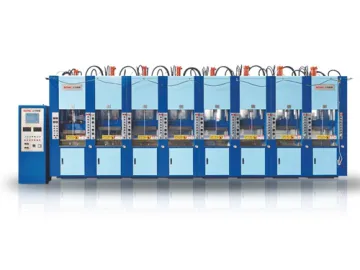

Linear EVA Injection Moulding Machine, ZF206E/ZH208E

Linear EVA Injection Moulding Machine, ZF206E/ZH208E

-

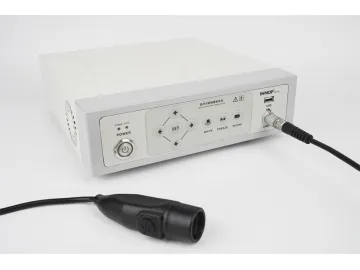

Full HD Endoscope Camera System, INP-200

Full HD Endoscope Camera System, INP-200

-

Two Colour Slipper Upper Strap Injection Moulding Machine, EB208D/EB210D

Two Colour Slipper Upper Strap Injection Moulding Machine, EB208D/EB210D

-

Inner Cone & Outer Cone Cable Connectors

Inner Cone & Outer Cone Cable Connectors

-

Insulating Cap

Insulating Cap

-

Self-Adaptive Permanent Self-Fusing Tape

Self-Adaptive Permanent Self-Fusing Tape

-

Two Colour Sandal Injection Moulding Machine, HB220Q/HB224Q

Two Colour Sandal Injection Moulding Machine, HB220Q/HB224Q

-

Veterinary Endoscope Camera System, INP-800

Veterinary Endoscope Camera System, INP-800

-

Two Colour Sandal Injection Moulding Machine, EA210QV/EA212QV

Two Colour Sandal Injection Moulding Machine, EA210QV/EA212QV

-

Automatic Rotary Injection Machine (One Mold for One Pair), EA110Q T/EA112Q T

Automatic Rotary Injection Machine (One Mold for One Pair), EA110Q T/EA112Q T

-

600A Separable Tee Connector

600A Separable Tee Connector

-

Single Colour Sandal Injection Moulding Machine, LA120Q/LA124Q

Single Colour Sandal Injection Moulding Machine, LA120Q/LA124Q