Automatic Dual Direction Drilling Tapping Machine

Description

The GS-20 automatic dual direction drilling tapping machine is mainly used for drilling and tapping processes in the production of wooden side plates. This machine is designed with a dual direction drilling device, and it can process 6 pieces of timber in one minute, and up to 2,000 pieces in 8 hours.

Parameters

| Tapping motor | 1hp×2 |

| Drilling motor | 1hp×2 |

| Servo motor | 400w |

| Manufacturing length | 150-450mm/15-35mm |

| Machine size(length*width*height) | 2000×1300×1400mm |

| Weight | 1200kg |

Drilling position and tapping position

Characteristics

This machine is designed with a dual direction drilling device. The hole position is precise, giving the equipment a high production efficiency. The loading process is operated automatically, saving labor costs. The user interface is clear and easy to operate. The high-quality motors and corresponding devices make the operation smooth and stable. The electric circuit is designed to showcase its quality and make operation simple and convenient.

Scan QR to Read

Links:https://www.globefindpro.com/products/14271.html

Links:https://www.globefindpro.com/products/14271.html

Recommended Products

-

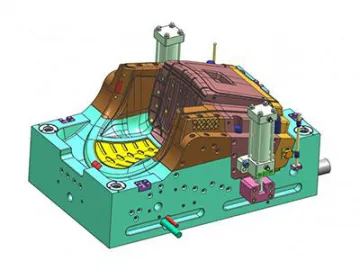

Learn About Plastic Injection Molding

Learn About Plastic Injection Molding

-

Multiple Spindle CNC Slot Mortiser (Vertical Type)

Multiple Spindle CNC Slot Mortiser (Vertical Type)

-

Concrete Floor Tile Mould

Concrete Floor Tile Mould

-

Hollow Construction Block Mould

Hollow Construction Block Mould

-

Paver Brick Mould

Paver Brick Mould

-

Curbstone Mould

Curbstone Mould

-

Plastic Injection Molds for PA Material Cable Accessories

Plastic Injection Molds for PA Material Cable Accessories

-

Automatic Seat Frame Drilling Cutting Machine

Automatic Seat Frame Drilling Cutting Machine

-

Automatic Single Side Drilling Doweling Tenoner

Automatic Single Side Drilling Doweling Tenoner

-

PS Champagne Flutes Injection Mold, Complex Mold Design

PS Champagne Flutes Injection Mold, Complex Mold Design

-

Heavy Duty Molds for Making PP Chair

Heavy Duty Molds for Making PP Chair

-

For making bedroom cabinet

For making bedroom cabinet

Hot Products