Film Granulator

Applications of the Film Granulator

3E film granulator’s economic applicability and professional rotor design can double the crushing efficiency and yield, which is suitable for film, jumbo bags, woven bags, plastic waste, PET packing tapes, high strength engineering plastic, rubber and other material. It can be supplied with automatic transmission device and sound insulation enclosure upon request. Because of the crushing process using water, the service life of the blade can be prolonged and the cleaning can be done simultaneously. Therefore, it has strong practicability, easy operation, long working life and other characteristics.

Structure chart

Technical Specifications of the Film Granulator

| Model Item | PC2660 | PC3260 | PC3280 | PC4280 | PC42100 | PC42120 |

| Dimension L/W/H (mm) | 1483×1328×1740 | 1486×1368×1711 | 1586×1568×1814 | 1770×1642×2425 | 1770×1842×2425 | 1760×2221×2530 |

| Cutting chamber C/D (mm) | 634×383 | 634×415 | 834×414 | 834×540 | 1034×540 | 1234×540 |

| E (mm) | 1567 | 1269 | 1369 | 1842 | 1842 | 1947 |

| Rotor Diameter (mm) | φ260 | φ320 | φ320 | φ420 | φ420 | φ420 |

| Main Shaft Speed (r/min) | 591 | 438 | 627 | 466 | 466 | 462 |

| Screen Mesh (mm) | φ8 | φ12 | φ12 | φ12 | φ12 | φ12 |

| Rotor-knives (PCS) | 3×2 | 3×2 | 3×2 | 3×2 | 3×2 | 3×2 |

| Stator-knives (PCS) | 2×2 | 2×2 | 2×2 | 2×2 | 2×2 | 2×2 |

| Main Motor Power (KW) | 15 | 15 | 22 | 37 | 45 | 55 |

| Weight (KG) | 890 | 1485 | 1646 | 2820 | 3230 | 3650 |

Rotor locking device & external bearing

Rotor locking device can fix the rotor with a bolt to avoid the harm caused by the rotation of the rotor when the cover is opened.

External bearing can effectively prevent moisture and dust from entering the bearing.

Screen

Different size and form of screen meet different needs of customers.

Spiral Discharging

The fragmentized material is discharged automatically through the screw conveyor to ensure the continuous production of the granulator.

Hopper

With the reinforced design, the hopper is strong and durable.

Links:https://www.globefindpro.com/products/14913.html

-

Aluminum Beams

Aluminum Beams

-

Aluminum Profile Section

Aluminum Profile Section

-

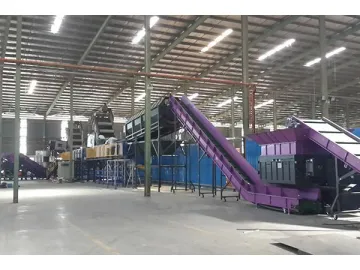

Agricultural Plastic Film Granulating, Washing, Drying Line

Agricultural Plastic Film Granulating, Washing, Drying Line

-

Square Tube with Flange

Square Tube with Flange

-

Aluminum Round Tube

Aluminum Round Tube

-

Diamonds, Tungsten Carbide

Diamonds, Tungsten Carbide

-

PDC Drilling Bits, Polycrystalline Diamond Compact Bits

PDC Drilling Bits, Polycrystalline Diamond Compact Bits

-

HDD Drill Pipe (Forged Type)

HDD Drill Pipe (Forged Type)

-

Hoisting Plug

Hoisting Plug

-

Drilling Subs

Drilling Subs

-

HDD Drill Pipe and Drilling Tools

HDD Drill Pipe and Drilling Tools

-

Overshot

Overshot