TJ250/45 Copper Flat Wire Line

Continuous Extrusion Machine for Copper Wire, Strip and Flat Wire

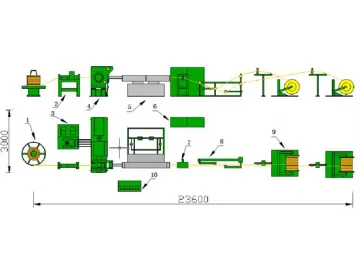

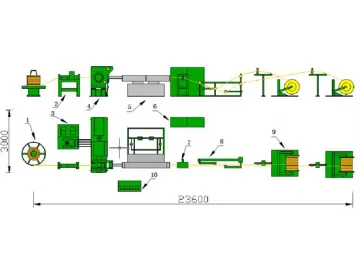

1. Payoff machine 2. Straightener 3. Continuous extrusion machine 4. Cooling and drying system 5. Meter Counter

6. Guide pulley 7. Takeup machine 8. Hydraulic and lubrication system 9. Electric control cabinet 10. Operation console

Technical Specifications

Main Components of the Production Line

Features The TJ250/45 flat copper wire continuous rotary extrusion line uses the Φ8mm oxygen-free copper rod made by the upward casting technique as the raw material. This material can be easily prepared. With special extrusion die design, this continuous extrusion equipment supports extrusion of two wires at the same time. This improves the production efficiency and dramatically cuts down the production cost. The extruded wires eliminate the need for further processing such as drawing, rolling, or annealing. While ensuring quality, the production cost and investment cost are both degreased. Related:

This product has been discontinued and removed from our shelves.

1. Payoff machine 2. Straightener 3. Continuous extrusion machine 4. Cooling and drying system 5. Meter Counter

6. Guide pulley 7. Takeup machine 8. Hydraulic and lubrication system 9. Electric control cabinet 10. Operation console

This continuous rotary extrusion line is suitable for producing flat copper wires with ultra small sections. The sectional area is about 2.5m2. The extruded products can be used to form enameled transposed conductors which are often used in EHV transformers.

Additionally, this range of continuous rotary extrusion machine is also commonly utilized to produce copper flat wires for use in motors, high power transformers, as well as industries such as military and aerospace, etc.

Technical Specifications

| Main Functional Unit: Continuous Extrusion Machine | |

| Model | TJ250 |

| Nominal Diameter of Extrusion Wheel | 250 mm |

| Rated Rotation Speed | 11RPM |

| Power of Main Motor | 45kW |

| Feed Stock (Copper Rod) | |

| Diameter | Φ 8.0 mm |

| Diameter Tolerance | ±0.2mm |

| Yield Strength | 160MPa (Oxygen-free Copper Rod Produced by Upward Casting Process) |

| End Product : Flat Copper Wires | |

| Sectional Area Range | 2.5-60mm² |

| Max. Width | 15mm |

| Standard | Conforms to GB5585.1-85 standard |

| Entire Production Line: Copper Wire Production Line | |

| Average Output | 100-150kg/h |

| Installed Capacity | 380V, 3 phase, 75KVA |

| Flash Amount | 1-2% |

| Workshop | |

| Minimum Dimension | Length: 22m, Width: 7 m, Height: 4 m |

| Cooling Water | 30 m3/h (Cooling Tower) |

| Compressed Air | 0.7 MPa, 1 m3/min |

| Operator | 2 |

| Copper Rod Payoff Machine | one set |

| Copper Rod Straightening Machine | one set |

| Copper Continuous Extrusion Machine | one set |

| Cooling and Oxidation-Prevention System (with Blow-drying Function) | one set |

| Meter Counter | two sets |

| Takeup Machine (630mm-800mm) | two sets |

| Electrical Control System (with Touch Screen) | one set |

| Hydraulic and Lubrication System | one set |

Continuous Extrusion Machine, Copper Extrusion Line, Continuous Rotary Extrusion Equipment Manufacturer

Scan QR to Read

Links:https://www.globefindpro.com/products/15138.html

Links:https://www.globefindpro.com/products/15138.html

Recommended Products

-

Hardcover Pressing Machine

Hardcover Pressing Machine

-

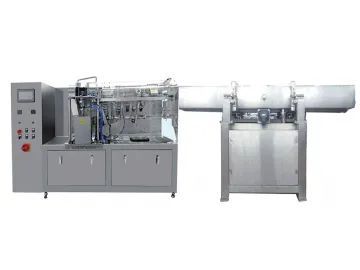

JDG-180D/240D, Pre-made bag Rotary System Pouch Packaging Machines

JDG-180D/240D, Pre-made bag Rotary System Pouch Packaging Machines

-

JDZ-180D/240D, Pre-made bag Rotary System Pouch Packaging Machines

JDZ-180D/240D, Pre-made bag Rotary System Pouch Packaging Machines

-

TJ550A Copper Bus Bar & Profile Line

TJ550A Copper Bus Bar & Profile Line

-

JDS-180D/240D Rotary System Pouch Packaging Machines

JDS-180D/240D Rotary System Pouch Packaging Machines

-

Semi Automatic Paper Gluing Machine

Semi Automatic Paper Gluing Machine

-

JDZ-180D/300D Rotary System Pouch Packaging Machines

JDZ-180D/300D Rotary System Pouch Packaging Machines

-

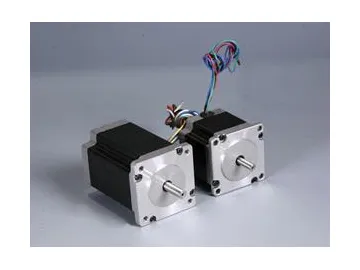

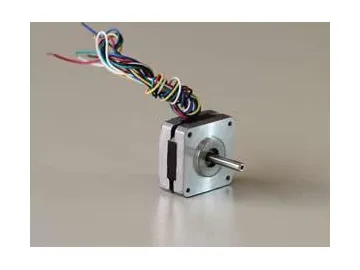

1.8 Degree Size 42mm 2-Phase High Torque Hybrid Stepper Motor

1.8 Degree Size 42mm 2-Phase High Torque Hybrid Stepper Motor

-

1.8 Degree Size 60mm 2-Phase High Torque Hybrid Stepper Motor

1.8 Degree Size 60mm 2-Phase High Torque Hybrid Stepper Motor

-

1.8 Degree Size 39mm 2-Phase Hybrid Stepper Motor

1.8 Degree Size 39mm 2-Phase Hybrid Stepper Motor

-

1.8 Degree Size 28mm Slim Pancake Hybrid Stepper Motor

1.8 Degree Size 28mm Slim Pancake Hybrid Stepper Motor

-

Pouch Packaging Machines

Pouch Packaging Machines

Hot Products