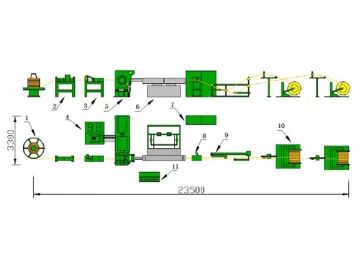

TJ550A Copper Bus Bar & Profile Line

Technical Specifications

| Model | TJ550 |

| Nominal Diameter of Extrusion Wheel(mm) | Φ550 |

| Power of Main Motor(kW) | 450 |

| Feed Stock Diameter(mm) | Φ22 |

| Copper Bar Max. Width(mm) | 300 |

| Copper Bar Max. Diameter(mm) | Φ110 |

| Sectional Area Range(mm²) | 300-5800 |

| Average Output (kg/h) | 2200 |

The continuous rotary extrusion line is especially designed for producing copper alloy trolley wires. The continuous extrusion machine, the key component of the production line, adopts the new die cavity featuring modular construction and high temperature resistance so as to extrude copper alloy products with the tensile strength up to 265N/mm2. Through deep processing one more time, the tensile strength can reach 650N/mm2.

This range of copper alloy trolley wire production line can effectively improve the constitution of extruded copper alloy wires, making the product structure densified and even. Thus, the requirements for high strength and high conductivity can be fully met. Additionally, our continuous rotary extrusion equipment makes use of the new abutment characterized by great strength and exceptional high temperature resistance. For this reason, this continuous rotary extrusion line is capable of manufacturing copper magnesium trolley wire with the magnesium content being 6‰. It is also ideal for extrusion molding of other types of copper alloy wires.

Related:

Copper Extrusion Line, Continuous Rotary Extrusion Equipment Manufacturer

Links:https://www.globefindpro.com/products/15142.html

-

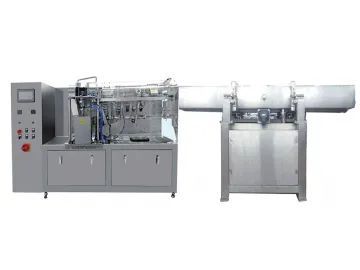

JDS-180D/240D Rotary System Pouch Packaging Machines

JDS-180D/240D Rotary System Pouch Packaging Machines

-

Semi Automatic Paper Gluing Machine

Semi Automatic Paper Gluing Machine

-

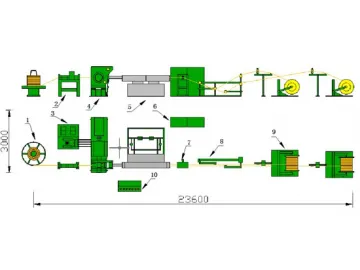

TJ300 Copper Flat Wire Line

TJ300 Copper Flat Wire Line

-

JDG-180/240, Pre-made bag Rotary System Pouch Packaging Machines

JDG-180/240, Pre-made bag Rotary System Pouch Packaging Machines

-

S600/S600A Automatic Rigid Box Making Machine

S600/S600A Automatic Rigid Box Making Machine

-

SW900 Automatic Grooving Machine

SW900 Automatic Grooving Machine

-

JDZ-180D/240D, Pre-made bag Rotary System Pouch Packaging Machines

JDZ-180D/240D, Pre-made bag Rotary System Pouch Packaging Machines

-

JDG-180D/240D, Pre-made bag Rotary System Pouch Packaging Machines

JDG-180D/240D, Pre-made bag Rotary System Pouch Packaging Machines

-

Hardcover Pressing Machine

Hardcover Pressing Machine

-

TJ250/45 Copper Flat Wire Line

TJ250/45 Copper Flat Wire Line

-

JDZ-180D/300D Rotary System Pouch Packaging Machines

JDZ-180D/300D Rotary System Pouch Packaging Machines

-

1.8 Degree Size 42mm 2-Phase High Torque Hybrid Stepper Motor

1.8 Degree Size 42mm 2-Phase High Torque Hybrid Stepper Motor