S600/S600A Automatic Rigid Box Making Machine

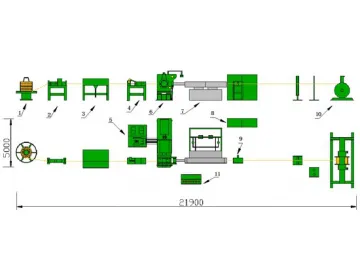

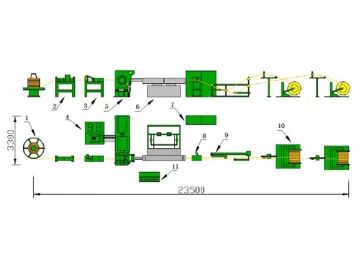

Rigid box manufacturing line, rigid box plant

S600 rigid box line S600A rigid box line Features

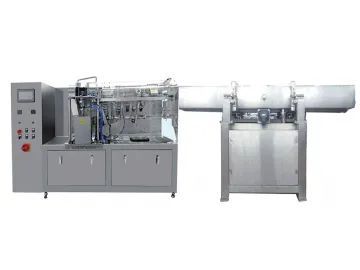

Forming and folding mechanism adopts mechanical and electrical pneumatic to solve the whole folding ear, middle folding ear.

Forming and folding mechanism adopt mechanical and pneumatic together to achieve full fold into the high-end 60mm

Feeder part: Feeder to achieve automatic delivery for wrap paper and cardboard, suck one sheet per time precisely, keep them no deviation during delivery.

Gluer part: Hot-melting glue system to automatic heating, circulation, mix the glue and precision to control the viscosity of glue, can also automatic wash up gluing tank after finish glue work.

Corner tapping part: Automatic folding cardboard and sticking its four corners by hot melt glue tape, then delivery it to named place of converying belt.

Spotter part: The hydraulic pneumatic spotter device combine with precision photoelectric detecting switch can to correcting and keep right positioning the sticked cardboard box on glued wrap paper.

Press part: The square press tooling can compact each conveying box that under its range, make the touch surface between wrap paper and cardboard more neat and smooth, expel air bubbles.

Box forming parts: Can continuous feeding, folding box, turn in box, box wrapped with one time finish.

Control panel: The convenient control panel equipped with sensitive touch screen-HMI system can freely transform between English and Chinese, make each operate turn to easy.

PLC Part: This machine adopts the advanced PLC, it can precision control and realize the details operation of automatic rigid box production process.

Parameters

Process

Samples

S600 rigid box line S600A rigid box line Features

Forming and folding mechanism adopts mechanical and electrical pneumatic to solve the whole folding ear, middle folding ear.

Forming and folding mechanism adopt mechanical and pneumatic together to achieve full fold into the high-end 60mm

Feeder part: Feeder to achieve automatic delivery for wrap paper and cardboard, suck one sheet per time precisely, keep them no deviation during delivery.

Gluer part: Hot-melting glue system to automatic heating, circulation, mix the glue and precision to control the viscosity of glue, can also automatic wash up gluing tank after finish glue work.

Corner tapping part: Automatic folding cardboard and sticking its four corners by hot melt glue tape, then delivery it to named place of converying belt.

Spotter part: The hydraulic pneumatic spotter device combine with precision photoelectric detecting switch can to correcting and keep right positioning the sticked cardboard box on glued wrap paper.

Press part: The square press tooling can compact each conveying box that under its range, make the touch surface between wrap paper and cardboard more neat and smooth, expel air bubbles.

Box forming parts: Can continuous feeding, folding box, turn in box, box wrapped with one time finish.

Control panel: The convenient control panel equipped with sensitive touch screen-HMI system can freely transform between English and Chinese, make each operate turn to easy.

PLC Part: This machine adopts the advanced PLC, it can precision control and realize the details operation of automatic rigid box production process.

Parameters

| Parameters | S 600 | S 600A | |

| Sheet size (A×B) | A min. Amax. B min. B max. | 95mm 610mm 180mm 850mm | 95mm 610mm 180mm 850mm |

| Cardboard size (C×D ) | C D | 600mm 800mm | 600mm 800mm |

| Sheet thickness | 100-200g/m2 | 100-200g/m2 | |

| Cardboard thickness | T | 0.8-3mm | 0.8-3mm |

| Finished box size (W ×L×H ) | Wmin. Wmax. L min. L max. H min. H max. | 50mm 400mm 100mm 600mm 15mm 150mm | 50mm 400mm 100mm 600mm 15mm 150mm |

| Edge folding depth | R min. R max. | 7mm 35mm | 7mm 60mm |

| Fold ear depth | R min. R max. | 10mm 125mm | 10mm 125mm |

| Positioning accuracy | ± 0.5mm | ± 0.5mm | |

| Production speed | ≦35 sheets/min | ≦35 sheets/min | |

| Sheet stacking height | 300mm | 300mm | |

| Cardboard stacking height | 1000 mm | 1000 mm | |

| Electrical power | 16kw/380V/3 phases | 16kw/380V/3 phases | |

| Glue barrel capacity | 60L | 60L | |

| Air supply | 12L/min. 0.6Mpa | 12L/min. 0.6Mpa | |

| Machine weight | 6800kg | 6800kg | |

| Machine dimension | L6600×W 4100×H 3250mm | L6600×W 4100×H 3250mm |

Remark

1.The max and min size of the boxes are affect by those size of material and quality of material.2.The detail production speed of this machine depend on several factors: raw materials, glue and the operator's skill.

Process

Samples

Scan QR to Read

Links:https://www.globefindpro.com/products/15147.html

Links:https://www.globefindpro.com/products/15147.html

Recommended Products

-

SW900 Automatic Grooving Machine

SW900 Automatic Grooving Machine

-

QTJ600/QTJ420 Automatic Box Tapping Machine

QTJ600/QTJ420 Automatic Box Tapping Machine

-

TJ400A Copper Bus Bar & Profile Line

TJ400A Copper Bus Bar & Profile Line

-

SW1000 Manual grooving machine

SW1000 Manual grooving machine

-

TJJ 700B Adjustable Speed Gluing Machine

TJJ 700B Adjustable Speed Gluing Machine

-

B460 Box Wrapper

B460 Box Wrapper

-

JDG-180/240, Pre-made bag Rotary System Pouch Packaging Machines

JDG-180/240, Pre-made bag Rotary System Pouch Packaging Machines

-

TJ300 Copper Flat Wire Line

TJ300 Copper Flat Wire Line

-

Semi Automatic Paper Gluing Machine

Semi Automatic Paper Gluing Machine

-

JDS-180D/240D Rotary System Pouch Packaging Machines

JDS-180D/240D Rotary System Pouch Packaging Machines

-

TJ550A Copper Bus Bar & Profile Line

TJ550A Copper Bus Bar & Profile Line

-

JDZ-180D/240D, Pre-made bag Rotary System Pouch Packaging Machines

JDZ-180D/240D, Pre-made bag Rotary System Pouch Packaging Machines

Hot Products