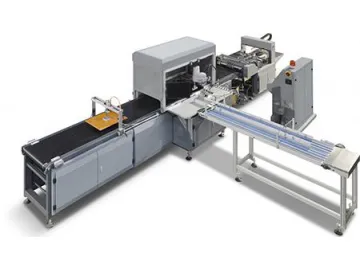

S18Y Fully Automatic Multifunction Gift Box Making Machine

Automatic all-in-one box making machine, rigid box line

It adopts high speed automatic paper feeding system, which is controlled pneumatically, and its structures simple and reasonable.

New designed copper scraper cooperates with the rubber more compactly, effectively avoiding paper winding. And the copper scraper is more durable

Paper feeding and positioning system adopt imported high precise photoelectric control device to make the paper and cardboard location more accurate.

It adopts PLC control, featuring in simple operation. The troubles are displayed directly on the HMI, which helps the operator easily remove them

Parameters

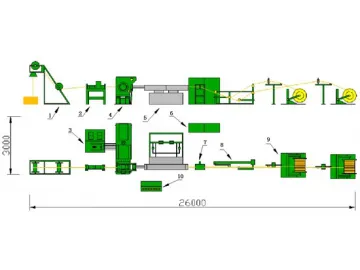

Workflow

Drawing

Samples

It adopts high speed automatic paper feeding system, which is controlled pneumatically, and its structures simple and reasonable.

New designed copper scraper cooperates with the rubber more compactly, effectively avoiding paper winding. And the copper scraper is more durable

Paper feeding and positioning system adopt imported high precise photoelectric control device to make the paper and cardboard location more accurate.

It adopts PLC control, featuring in simple operation. The troubles are displayed directly on the HMI, which helps the operator easily remove them

Parameters

Case maker unit

| Sheet length | 190-1030mm |

| Sheet width | 130-600mm |

| Sheet thickness | 80~200g/m2 |

| Cardboard thickness | 1-3mm |

| Min. width of spine | 8mm |

| Speed | 0-30pcs/min |

| Power | 13kw |

| Machine weight | 4000kg |

| Machine dimension | L11000×W5000×H2800mm |

Box wrapper unit

| Box size | Max. | Min. |

| 420mm | 100mm | |

| 320mm | 50mm | |

| 150mm | 15mm | |

| Sheet thickness | 80-200g | |

| Cardboard thickness | 1.5-3mm | |

| Fold ear depth | 125mm | |

| Edge folding depth | 100mm | 20mm |

| Positioning accuracy | ± 0.3mm | ± 0.1mm |

| Production speed | ≦20 sheets/min |

Workflow

Drawing

Samples

Scan QR to Read

Links:https://www.globefindpro.com/products/15160.html

Links:https://www.globefindpro.com/products/15160.html

Recommended Products

-

B460A Box Wrapper

B460A Box Wrapper

-

QJH 460Y Automatic Wine Box Making Machine

QJH 460Y Automatic Wine Box Making Machine

-

SJ420Y/SJ420YS Automatic Visual Position Rigid Box Making Machine

SJ420Y/SJ420YS Automatic Visual Position Rigid Box Making Machine

-

LJ300 Al Flat Wire & Sector Line

LJ300 Al Flat Wire & Sector Line

-

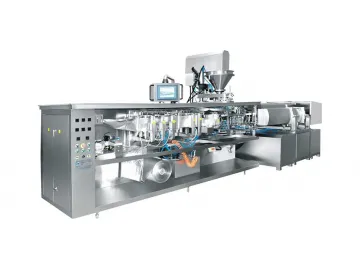

JDZ-120/160/240 Rotary System Pouch Packaging Machines

JDZ-120/160/240 Rotary System Pouch Packaging Machines

-

SJ460Y/600Y Automatic Box Visual Positioning Machine

SJ460Y/600Y Automatic Box Visual Positioning Machine

-

S460Y/240YS/S600Y Automatic Rigid Box Making Machine

S460Y/240YS/S600Y Automatic Rigid Box Making Machine

-

JDS-180/240 Rotary System Pouch Packaging Machines

JDS-180/240 Rotary System Pouch Packaging Machines

-

ZH500 Semi Auto Spray Adhesive Machine

ZH500 Semi Auto Spray Adhesive Machine

-

JD-180/240 Rotary System Pouch Packaging Machines

JD-180/240 Rotary System Pouch Packaging Machines

-

SW1350 Cardboard Slitting Machine

SW1350 Cardboard Slitting Machine

-

JDZ-180/240, Pre-made bag Rotary System Pouch Packaging Machines

JDZ-180/240, Pre-made bag Rotary System Pouch Packaging Machines

Hot Products