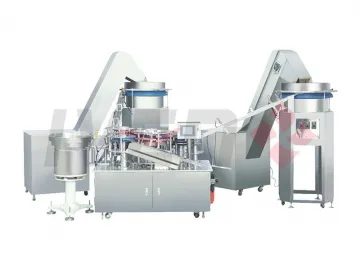

Inline Liquid Filling Machine

The inline liquid filling machine is used for capping, vacuumizing and tray loading during the production of blood collection tubes. With a high degree of integration, a small floor space, a high production efficiency, and a stable, reliable operation, this machine is popular within the pharmaceutical industry.

Equipment features

The cap and stopper feeding area is set with a buffer zone to provide high feeding efficiency. The unique cap picking and distance adjustment device allows for a smoother and more stable capping process.

High efficiency vacuum pump and high precision proportioning control achieves a full control of the vacuum degree. The vacuum degree can be set directly on the touch screen or automatically in the system after choosing the atmospheric pressure of your location.

Trays come in staggered and matrix arrangement type, offering customers with wider choices.

Technical specs

| Capacity | 15,000-18,000 pcs/h |

| Vacuum range | 0 ~ -99.9kPa |

| Compressed air consumption | <100L /min, 0.5-0.8Mpa |

| Power supply | AC 380V / 50Hz |

| Power | 0.7Kw |

| Overall size (L*W*H) | 2000*1200*2000 mm |

Scan QR to Read

Links:https://www.globefindpro.com/products/15293.html

Links:https://www.globefindpro.com/products/15293.html

Recommended Products

-

Liquid Storage Tank

Liquid Storage Tank

-

Processing Equipment for Evacuated Blood Collection Tubes (Modular Type)

Processing Equipment for Evacuated Blood Collection Tubes (Modular Type)

-

Dosing Machine

Dosing Machine

-

Automatic Syringe Assembly Line

Automatic Syringe Assembly Line

-

Printing Machine

Printing Machine

-

Manufacturing Capability

Manufacturing Capability

-

Rotary Capping Machine

Rotary Capping Machine

-

Lifting Turnover granulator

Lifting Turnover granulator

-

Plaster Rock Wool Sandwich Panel

Plaster Rock Wool Sandwich Panel

-

Magnesium Honeycomb Sandwich Panel

Magnesium Honeycomb Sandwich Panel

-

Rock Wool Panel

Rock Wool Panel

-

Cleanroom Pass-through Chamber

Cleanroom Pass-through Chamber