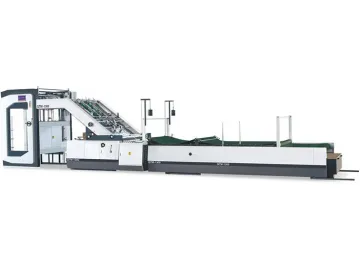

High Speed Folder Gluer (4/6 Corner)

Features

The 4/6 corner high speed folder gluer has the advantages of unilateral transmission structure, operation stability and simple safeguarding.

Thanks to the use of motor inverter, this paperboard gluing machine can achieve automatic speed control and is energy-saving.

Double-sided tooth-conditioning makes machine operation easy.

The high speed folder gluer can output paper continuously, accurately and automatically through a number of thickened belts with vibration motors.

The main transmission belt works vertically to minimize wear.

Glue tubes can be automatically adjusted, making the high speed folder gluer easy to operate. (Various glue-jet spray systems are optional.)

Our paper box gluer features more comprehensive functions by employing PLC and human-computer operating system, remote diagnosis system, remote control maintenance system as well as photoelectric counting system. The quantitative counting system can be equipped with automatic paper kicking device or spray device.

The conveying platen of our high speed folder gluer is made of special material and is equipped with a sponge belt to protect the finished products against damage.

High-power servo control system is used in our corrugated board gluing equipment to ensure product quality.

This equipment is suitable for producing two-fold, four-fold, four-corner and six-corner cardboards as well as gluing packaging boxes.

Technical Parameters of High Speed Folder Gluer

Applicable Box Types and Sizes

The 4/6 corner high speed folder gluer has the advantages of unilateral transmission structure, operation stability and simple safeguarding.

Thanks to the use of motor inverter, this paperboard gluing machine can achieve automatic speed control and is energy-saving.

Double-sided tooth-conditioning makes machine operation easy.

The high speed folder gluer can output paper continuously, accurately and automatically through a number of thickened belts with vibration motors.

The main transmission belt works vertically to minimize wear.

Glue tubes can be automatically adjusted, making the high speed folder gluer easy to operate. (Various glue-jet spray systems are optional.)

Our paper box gluer features more comprehensive functions by employing PLC and human-computer operating system, remote diagnosis system, remote control maintenance system as well as photoelectric counting system. The quantitative counting system can be equipped with automatic paper kicking device or spray device.

The conveying platen of our high speed folder gluer is made of special material and is equipped with a sponge belt to protect the finished products against damage.

High-power servo control system is used in our corrugated board gluing equipment to ensure product quality.

This equipment is suitable for producing two-fold, four-fold, four-corner and six-corner cardboards as well as gluing packaging boxes.

Technical Parameters of High Speed Folder Gluer

| Paper suitable | 250-800gsm, flute E & F |

| Feeding type | Continuously |

| Maximum speed | 300m/min |

| Box width | 120mm-1050mm |

| Machine dimension | 16.2×1.9×1.5m |

| Weight | 9500kg |

| Total power | 29kW |

Applicable Box Types and Sizes

| Type of box | Straight line box | Crash bottom box | Both-side box | Four corner box | Six corner box |

| Maximum size | 1050×900 | 1050×900 | 1000×900 | 1000×900 | 1000×900 |

| Minimum size | 120×80 | 240×80 | 120×80 | 160×120 | 280×120 |

Scan QR to Read

Links:https://www.globefindpro.com/products/15357.html

Links:https://www.globefindpro.com/products/15357.html

Recommended Products

-

Single Facer Overhead Conveying System

Single Facer Overhead Conveying System

-

Chain Feed Carton Flexo Printing Machine

Chain Feed Carton Flexo Printing Machine

-

Automatic Die Cutting and Creasing Machine (Manual-Automatic Feeder with Stripping Unit)

Automatic Die Cutting and Creasing Machine (Manual-Automatic Feeder with Stripping Unit)

-

Mechanical Shaftless Mill Roll Stand

Mechanical Shaftless Mill Roll Stand

-

Automatic Sheet Delivery Stacker

Automatic Sheet Delivery Stacker

-

Printer Slotter (with Die Cutting and Stacking Function)

Printer Slotter (with Die Cutting and Stacking Function)

-

High Speed Automatic Flute Laminating Machine

High Speed Automatic Flute Laminating Machine

-

Hand Platen Foil Stamping Creasing Machine

Hand Platen Foil Stamping Creasing Machine

-

Automatic Corrugated Board Die Cutting and Creasing Machine

Automatic Corrugated Board Die Cutting and Creasing Machine

-

MY-1050 Automatic Die Cutting and Creasing Machine

MY-1050 Automatic Die Cutting and Creasing Machine

-

Single Face Corrugated Sheet Production Line

Single Face Corrugated Sheet Production Line

-

Corrugated Sheet Cutting Machine

Corrugated Sheet Cutting Machine