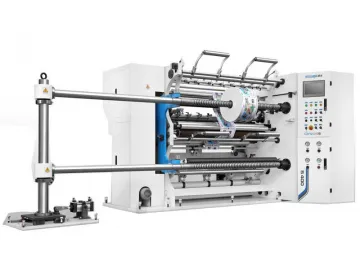

Automatic Roll to RollSlitter Rewinder Machine

The GSFQ1300B slitting machine is controlled by a servo motor and PLC controller. It is equipped with a hydraulic infeed device and laser positioning device to ensure the paper core remains in position. This roll to roll slitter rewinder has a high efficiency, and is capable of slitting 40mm of material/minute, which makes it ideal for clients with requirements for mass production.

This machine is ideal for slitting large width rolls into smaller width rolls, and is suitable for a variety of plastic film materials, including Bopp, pvc, pe, pet, cpp, nylon and paper, non-woven, and PP woven.

Technical specification:| Model | GSFQ1300B |

| Width | 1300mm |

| Unwind diameter | 800mm |

| Rewind diameter | 600mm |

| Paper core diameter | 76mm or 152mm |

| Slitting speed | 400m/min |

| Slitting width | 30-1300mm |

| Slitting precision | 0.5mm |

| Power | 11KW |

| Weight | 4000KG |

| Dimension | 4200×2800×1800mm |

Scan QR to Read

Links:https://www.globefindpro.com/products/15560.html

Links:https://www.globefindpro.com/products/15560.html

Recommended Products

-

Roll Paper Slitting Machine

Roll Paper Slitting Machine

-

Wide Format Printing Flexographic Press

Wide Format Printing Flexographic Press

-

Full Color Flexo Printing Press

Full Color Flexo Printing Press

-

3-Layer 46kV Tree Wire

3-Layer 46kV Tree Wire

-

Printing on Flexible Packaging Bag

Printing on Flexible Packaging Bag

-

0.6/1 kV NAYY Cable(AL/PVC/PVC)

0.6/1 kV NAYY Cable(AL/PVC/PVC)

-

Tape and Paper Roll Printing

Tape and Paper Roll Printing

-

High Speed Gravure Printing Press, DNAY800F/1100F Package Printing

High Speed Gravure Printing Press, DNAY800F/1100F Package Printing

-

2-Layer 15kV Tree Wire

2-Layer 15kV Tree Wire

-

Industrial Flexographic Press

Industrial Flexographic Press

-

0.6/1 kV NAYBY Cable (AL/PVC/STA/PVC)

0.6/1 kV NAYBY Cable (AL/PVC/STA/PVC)

-

Adhesive Tape Slitter Machine

Adhesive Tape Slitter Machine

Hot Products