Side Sealing Pouch Making Machine

The GX400-600 bag making machine seals plastic bags using a temperature of up to 300℃ (the temperature is adjustable). It is mainly used for making three sided sealed bags such as bags for snacks, flour and tea. The top speed of this cutter is 60 bags/min.

| Model | 400 | 500 | 600 |

| Max material width | 850mm | 1050mm | 1250mm |

| Max Roll Diameter | 600mm | 600mm | 600mm |

| Bag Making Speed | 160 piece/min | 160 piece/min | 160 piece/min |

| Max Linear Speed | 40m/min | 40m/min | 40m/min |

| Total Power | 35KW | 40KW | 45KW |

| Weight | 4000KG | 4500KG | 5000KG |

| Dimension | 9000×1800×1870mm | 9000×1900×1870mm | 9000×2000×1870mm |

Scan QR to Read

Links:https://www.globefindpro.com/products/15602.html

Links:https://www.globefindpro.com/products/15602.html

Recommended Products

-

PE Blown Film Extrusion Plant

PE Blown Film Extrusion Plant

-

Drilling Hose

Drilling Hose

-

G Series High Power Fiber Laser Cutting Machine

G Series High Power Fiber Laser Cutting Machine

-

Crankshaft, Forged Pump Parts

Crankshaft, Forged Pump Parts

-

Pneumatic Clutch

Pneumatic Clutch

-

Hydraulic Tools

Hydraulic Tools

-

Automatic Industrial Cutter

Automatic Industrial Cutter

-

Hammer Union, Oilfield Components

Hammer Union, Oilfield Components

-

Flanges and Cylinder Parts

Flanges and Cylinder Parts

-

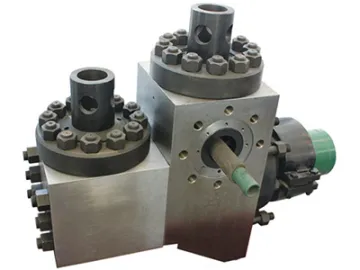

Fluid End Module, Mud Pump Components

Fluid End Module, Mud Pump Components

-

AAC Concrete Panels

AAC Concrete Panels

-

Oilfield Valves

Oilfield Valves