G Series High Power Fiber Laser Cutting Machine

G series high power fiber laser cutting machine can provide fiber laser with high power which can be up to 30000W to realize highly efficient thick metal sheet cutting. The strong machine body structure makes the machine running more stable and the lightweight cross beam makes the work more effectively. The machine is controlled by high quality electrical software so that the cutting precision can be guaranteed in high level. The cross-section of material processed by this machine features good quality cutting kerf, thus, there is no need of secondary processing. The overall time of workpiece processing is reduced by 30%.

The processing format of G series laser cutting machine can be up to 20500mm×3200mm which can satisfy the requirements of ultra-long workpiece processing. During the process of workpiece cutting, the database of BODOR control system can provide cutting parameters for performance and energy saving. This can reasonably save cost during cutting.

Equipment Features Features Integrated welding machine bodyThe integrally welded machine bed is made of flake graphite cast iron with a minimum tensile strength of 200MPa. It features high strength, strong wear resistance and stable processing precision, ensuring stability and service life of laser cutting machine under high power running. The aluminum cross beam has characteristics of high strength and light weight, so that it can be applied under high speed movement.

Ultra-fast perforatingG series high power fiber laser cutting machine can realize ultra-fast stepless perforating. It can greatly reduce the perforating time by 60%. The starting and follow up production steps remain in a stable and high precision work status. This cutter is time and energy saving with less slag. The utilization ratio of the material is improved and the wear rate of the cutting machine can be efficiently reduced. By selecting this mode, the time of debugging can be saved. Meanwhile, there is no requirement on specific skills for operators.

Operating system from Beckhoff, GermanThe operating system can be custom-engineered. Beckhoff can provide custom Bodor operation interface and special functions. It supports multi-touch screen, and achieves remote monitoring of running state of the laser cutting machine. With EtherCat bus control, high speed cutting can be easily implemented due to rapid signal transmission and high synchronization accuracy.

Auto Focus laser headThe Auto Focus laser head is suitable for cutting of sheet material of different thickness. Both collimating lens and focal lens apply compound lens to get the optimal optical quality and cutting effect. The lightweight structure is designed to provide laser head with good accelerating capability and high cutting speed.

RADAN Nest SoftwareThe RADAN Nest Software can realize batch processing of DXF, DWG or IGES files with drag and drop operation. The data exchanging with Windows interface simplifies the common functions. The flexible lead-in, lead-out, micro-joining and overcut setting enhance the operating experience of our customers. The cutting sequence optimization avoids collision, it improves the safety of application of G series laser cutting machine. The automatic quick estimation of part-cost helps customer reduce the labor intensity.

Touch screen21.5 inch touch screen with UI design can work in concert with the processing platform so that the application of G series laser cutting machine can be more visualized. The elegant curves precisely fit machine body.

Configuration Germany Rexroth servo motor and driverTaiwan guide rail and rack

Germany Stober gear motor

Japan SMC high pressure gas pipe

France Schneider breaker and relay

Switzerland CARLO GAVAZZI power switch

Germany Phoenix terminal

America Parker N2 cutting gas control valve

Japan SMC O2 cutting gas control valve GERMAN REXROTH SERVO

GERMAN REXROTH DRIVER

FRANCE SCHNEIDER

GERMANY STOBER

Functions Auxiliary gas low pressure alarming function

G series high power fiber laser cutting machine provides real-time pressure inspection. When the pressure is lower than that can provide best cutting effect and precision, the machine will send the information of abnormal status so that the gas supply can be replaced timely thus ensuring good cutting effect and precision.

WIFI remote and intelligent assistanceThe WIFI remote and intelligent assistance can realize global real-time feedback, providing real time failure analysis and trouble shooting.

Automatic lubricating systemThe automatic lubricating system provides quantitative lubricating oil for laser cutting machine regularly to ensure its smooth and high speed running. This system is also equipped with abnormity warning and liquid level alarm functions. It greatly increased the cutting precision and prolonged the service life of transmission mechanism.

Intelligent alarm systemThis intelligent alarm system provides comprehensive abnormity alarm function. It will also show the information on the interface so that operator can notice the abnormity of the machine previously, reducing potential danger.

Parameters| Model | G20 | G16 | G12 |

| Working Area | 20500*3200mm | 16500*3200mm | 12500*3200mm |

| Laser Output Power | 30000w/20000w/15000w/12000w/10000w/8000w/6000w/4000w/3000w | ||

| X/Y-axis positioning accuracy | 0.05mm | ||

| X/Y-axis repositioning accuracy | 0.025mm | ||

| X/Y-axis Max. linkage speed | 80m/min | ||

Cutting Capacity Outline Dimensions

Links:https://www.globefindpro.com/products/15605.html

-

Crankshaft, Forged Pump Parts

Crankshaft, Forged Pump Parts

-

Pneumatic Clutch

Pneumatic Clutch

-

Hydraulic Tools

Hydraulic Tools

-

Cut to Length Line (Paper Roll to Sheet Cutter)

Cut to Length Line (Paper Roll to Sheet Cutter)

-

Rubber Belt, V Belt

Rubber Belt, V Belt

-

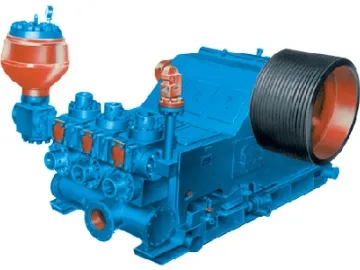

Mud Pump 3NB Series, Drilling Mud Pump

Mud Pump 3NB Series, Drilling Mud Pump

-

Drilling Hose

Drilling Hose

-

PE Blown Film Extrusion Plant

PE Blown Film Extrusion Plant

-

Side Sealing Pouch Making Machine

Side Sealing Pouch Making Machine

-

Automatic Industrial Cutter

Automatic Industrial Cutter

-

Hammer Union, Oilfield Components

Hammer Union, Oilfield Components

-

Flanges and Cylinder Parts

Flanges and Cylinder Parts