Split Type Vertical EPS Light Weight Wall Panel Production Line

The compound insulated concrete wall panel production line adopts sub and mother mould for automatic molding, curing and circulating production. It can produce composite lightweight insulated wall panel from EPS particles, XPS particles, ceramsite, modified perlite and some other light materials.

This production line consists of automatic batching plant, material metering and transporting equipment, continuous mixing station and material feeding system, sub and mother mould cart, ferry trolley, tumbler, mould stripping machine etc.

Supporting equipment: Cement silo Screw conveyor Mixing system Mixing system EPS silo Mould vehicle Ferry trolley Rotating machine Mould stripping system Automatic pallet tumbler Control system Vehicle Forklift Finished product stacking yardBecause of the separated sub mould and mother mould design and the mother mould is on the production line, when the sub mould is gathered in the curing chamber, the mother mould can continuously flow along the line, carrying the other sub mould. So, the production site and scale will not be limited because of on line curing. Thus it can provide larger productivity with limited production site.

Technical parameters:

| Finished wall panel dimension | 3000 / 2440 × 610 × 75/90/100/120/150 / 180mm | |

| Wall panel yield of different thickness | 75mm | 40 pieces |

| 90mm | 36 pieces | |

| 100mm | 32 pieces | |

| 120mm | 28 pieces | |

| 150mm | 24 pieces | |

| Dimension | 3350 × 1640 × 2920mm | |

| Weight | 4.2T | |

Configuration:

This compound insulated concrete wall panel production line is equipped with the following devices:

Vertical mould (vertical split casting); Sub and mother mould which is also called sub and mother mould cart. It consists of vehicle and die set; One sub and mother mould vehicle consists of 2 sub and mother mould and vehicle;

Automatic mould tumbler; Specific mould stripping machine.

Links:https://www.globefindpro.com/products/15768.html

-

Control system

Control system

-

Complete Can Beverage Filling and Packaging Line

Complete Can Beverage Filling and Packaging Line

-

Germany Technology Best Service

Germany Technology Best Service

-

Curing chamber

Curing chamber

-

Cuber system

Cuber system

-

Loading Platform

Loading Platform

-

Automatic Pallet Shrink Wrapping Machine

Automatic Pallet Shrink Wrapping Machine

-

Portable Construction Crane for Lifting, Shifting, Installing and Maintaining

Portable Construction Crane for Lifting, Shifting, Installing and Maintaining

-

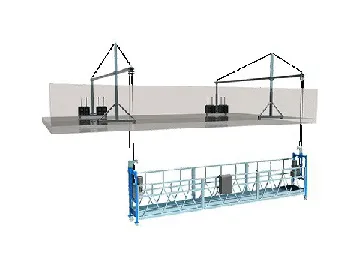

Custom Suspended Platform

Custom Suspended Platform

-

Germany Technology Best Service

Germany Technology Best Service

-

Economical Automatic Bottle Blow Molding Machine

Economical Automatic Bottle Blow Molding Machine

-

Germany Technology Best Service

Germany Technology Best Service