QT4-20 Automatic Block Making Machine

Description

Seen from the model number of the QT4-20 automatic block making machine, the product is capable of making 4 blocks in size of 400×200×200mm by each mould and the operation cycle lasts 20 seconds. Additionally, our product has the production capacity of 5000 blocks or 80 cubic meters of bricks within 8 working hours. Due to the changeable moulds, this automatic block making machine is available in forming diversified blocks, bricks and other products.

| Main Technical Specifications | |

| Production per mould | 4pcs/mould (Standard block: 400×200×200mm) |

| 24pcs/mould (Solid block: 240×115×53mm) | |

| 12pcs/mould (Hollow block: 240×115×90mm) | |

| 14 pcs/mould (Holland brick: 200×100×60-80mm) | |

| Cycle time | 20-30 seconds |

| Production per shift (8 working hours) | Hollow block (400×200×200mm): 5,000pcs |

| Solid block (240×115×53mm): 24,000pcs | |

| Hollow block (240×115×90mm): 12,000pcs | |

| Holland brick (200×100×60-80mm): 14,000pcs | |

| Vibration frequency | 2900rolls/minute |

| Vibrating force | 50kN |

| Motors power | 18.5kw |

| Machine dimensions | 4500×3000×2500mm |

| Pallet size | 880×540mm |

| Gross weight | about 4.5T |

| Raw materials | Crushed stone, sand, cement, dust and coal fly ash, cinder, slag, gangue, gravel, perlite and other industrial waste. |

| Applicable products | Concrete blocks, solid, hollow and cellular masonry products, paving stones with or without face mix, garden and landscaping products, slabs, curbstones, grass blocks, slope blocks, interlocking blocks, etc. |

| Applied fields | Suitable for buildings, road paving, squares, gardens, landscaping, city constructions, etc. |

| Note: All the production parameters are subject to change without prior notice. | |

Simple Production Line for Block Making

Process: Batching, automatic mixing, automatic molding or block producing, stacking in pile, moving by forklift. (12 workers needed)

1. Aggregate weighing system

2.Mixer

3.Belt conveyor

4. Automatic block making machine

5.Control system

6.Piler

Block and Brick Models

Links:https://www.globefindpro.com/products/15783.html

-

Curving Machine

Curving Machine

-

QGM International

QGM International

-

QGM Zenith Mold in Austria

QGM Zenith Mold in Austria

-

Lifting Machine

Lifting Machine

-

ZN1200S Automatic Block Making Machine

ZN1200S Automatic Block Making Machine

-

Scissors Aerial Work Platform

Scissors Aerial Work Platform

-

Curbstone Making Machine SZ-250T 300T

Curbstone Making Machine SZ-250T 300T

-

Colored Steel Coils

Colored Steel Coils

-

Suspending Mechanism (Parapet Clamp)

Suspending Mechanism (Parapet Clamp)

-

Unlimited Length Ridge Tile Forming Machine

Unlimited Length Ridge Tile Forming Machine

-

Special Suspended Platform, Gondola

Special Suspended Platform, Gondola

-

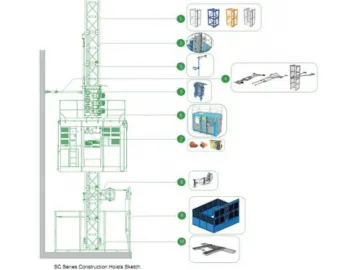

SC Series Construction Hoist

SC Series Construction Hoist