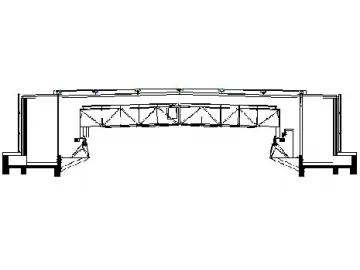

Highway Guardrail Roll Forming Machine

Profile Drawing Main Technical Specifications Rolling material: 2-3mm thickness, inclSpecification of rolling material: Width: 480mm; thickness: 3-4mm; Q235A galvanized steel sheet Working speed: 10 -12m/min Roller steps: 13 pairs main rollers & 7 pairs flattening rollers Material of roller: GCr15 bearing steel, quenched, HRC58℃-62℃ Material of main shaft: Superior 45# steel, tempered Diameter of main shaft: ¢85mm Main motor power: 35kw Transmission: Double-row chain drive Structure of forming machine: Wallboard Flattening motor power: 2.2kw Hydraulic motor power: 11kw, pressure: 20Mpa Material of punching and cutting mould: Cr12 Cutting blade heat-treated: HRC58℃-60℃ Punching and cutting way: Adopts hydraulic driving, flat panel punching, cutting after roll forming. Electric control system: Whole machine adopts PLC frequency control, cut-to-length error≤±2mm Machine dimension: 13500mm×2700mm×1600mm

Equipment Configuration

Manual Feeding device (3t capacity), transmission, flattening device, before-punching device (2 sets), main machine and roller (including guide table), cutting (after roll forming) device, hydraulic system, electric control system, run out table, etc.

Production Process

Manually uncoiling →Feeding & correcting→ Seven rollers flattening device → Flat panel punching→ Roll forming → Cutting after roll forming → Finished product

Scan QR to Read

Links:https://www.globefindpro.com/products/15802.html

Links:https://www.globefindpro.com/products/15802.html

Recommended Products

-

BH-HP -220B PU Foam Spray Equipment

BH-HP -220B PU Foam Spray Equipment

-

Aluminum Alloy Suspended Platform, Cradle, Swing Stage

Aluminum Alloy Suspended Platform, Cradle, Swing Stage

-

Highway Guardrail Roll Forming Machine

Highway Guardrail Roll Forming Machine

-

Trussing Type Window Cleaning Machine

Trussing Type Window Cleaning Machine

-

Corrugated Roof Sheet Forming Machine

Corrugated Roof Sheet Forming Machine

-

Concealed Roof Sheet Forming Machine

Concealed Roof Sheet Forming Machine

-

LTD Hoist Motor / Winch

LTD Hoist Motor / Winch

-

Building Cargo Hoist

Building Cargo Hoist

-

Single Person Suspended Platform

Single Person Suspended Platform

-

ZLT600 Double Layer Suspended platform for Elevator Installation

ZLT600 Double Layer Suspended platform for Elevator Installation

-

QT4-25 Automatic Block Making Machine

QT4-25 Automatic Block Making Machine

-

Double Layer Roll Forming Machine

Double Layer Roll Forming Machine

Hot Products