NEW DODO-400D Automatic Canbody Welder

This automatic canbody welder is designed for manufacturing milk powder cans and other large can types. It can achieve high quality rounding and welding processes.

Features

The electronic control system of the automatic canbody welder consists of an easy to use interface, PLC system, and servo system.

Its static variable frequency power source provides stability and minimizes energy consumption. It has its own independent air conditioning system.

The automatic fault detection system will automatically sound an alarm in the event of a malfunction and then provide you with troubleshooting solutions.

Using a special rounding device, the equipment can process various types of tinplate for different can bodies. It is also equipped with an automatic double sheet monitoring and ejection system.

A ceramic roller is equipped to profile copper wire that greatly improves insulation and reduces wear and tear. It is outfitted with a roller cooling device to prevent parts from overheating during copper wire profiling.

The copper wire profiling system is equipped with a rodless cylinder and cooling system with tension compensation and a tension monitoring function. It can ensure the tension, ductility, and line speed of copper wire so as to improve the overall welding quality.

The conveying system features ceramic parts to prevent damage to the can body.

The Z-rail is made of super wear-resistant ceramic material.

Servo based can feeding system offers high speed can feeding and stable running minimized noise.

This machine has a protective shield and support front and rear seam attenuation control. It is suitable for DR tinplate and normal tinplate.

It has Internal and external nitrogen protection devices.

It uses high quality pneumatic components manufactured by MAC, Festo, and SMC.

Technical Specifications

| Welding speed | 55m/min(max) |

| Production output | Can size #401: 300cans/min(Max) Can size #502:250cans/min(Max) Can size #603:200cans/min(Max) |

| Welding points distance | 0.5~0.9mm |

| Overlap width | 0.25~0.6mm |

| Sheet thickness | 0.16~0.30mm |

| Can inner diameter range | ¢52~¢153mm |

| Can height range | 65~305mm |

| Hardness | T2.5~DR8 |

| Wire diameter | ¢1.24~1.38mm |

| Power supply | Three phase Voltage:380V Frequency: 50Hz Power consumption:35Kw |

| Welding frequency | 200~450Hz |

| Cooling water | >0.5MPa,12~18℃,50L/min |

| Air pressure and consumption | >800L/min, >0.5MPa |

Scan QR to Read

Links:https://www.globefindpro.com/products/15978.html

Links:https://www.globefindpro.com/products/15978.html

Recommended Products

-

Automated powder-coating machine for weld seam protection

Automated powder-coating machine for weld seam protection

-

NEW DODO-500 Automatic Canbody Welder

NEW DODO-500 Automatic Canbody Welder

-

MAZDA Engine Carburetor

MAZDA Engine Carburetor

-

DAIHATSU & DAEWOO & KIA & FORD & CHEVROLET & GM Engine Carburetor

DAIHATSU & DAEWOO & KIA & FORD & CHEVROLET & GM Engine Carburetor

-

Exercise Book Stitching and Folding Machine

Exercise Book Stitching and Folding Machine

-

NEW DODO-300D Automatic Canbody Welder

NEW DODO-300D Automatic Canbody Welder

-

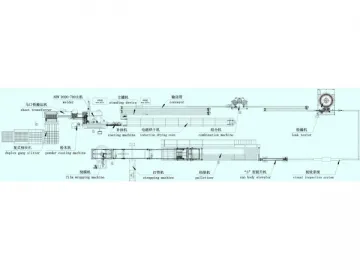

Three-piece Can Production Line

Three-piece Can Production Line

-

NEW DODO-700 Automatic Canbody Welder

NEW DODO-700 Automatic Canbody Welder

-

Transfer System

Transfer System

-

NEW DODO-60D Automatic Canbody Welder

NEW DODO-60D Automatic Canbody Welder

-

Square Book Back Making Machine

Square Book Back Making Machine

-

Gray Board V Grooving Machine

Gray Board V Grooving Machine

Hot Products