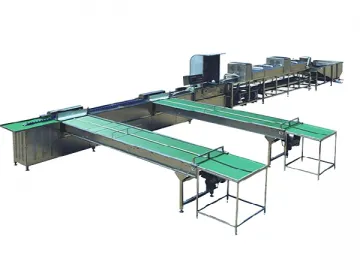

202B Egg Washer (10000 EGGS/HOUR)

The ZENYER 202B egg washer includes the processes of water bath loading, candling, brushing and drying. It is suitable for pre-separating or cleaning and drying for duck eggs or preserved eggs. This model can also be attached with a ZENYER egg grader or egg separator to make an assembly line. This egg washer is flexible on production speed and the maximum capacity reaches 10000 eggs/hour.

Specifications

| Product name | Egg cleaning machine |

| Product code | 202B |

| Model | ZYX-YS1-3 |

| Capacity | 10000 eggs/hour |

| Material | Stainless steel |

| Power | 6.3 KW |

| Voltage | 380V,50HZ, three phase |

| Dimension(L×W×H) | 7.3*1.7*1.1M |

| Function | Water bath loading, brushing, air drying, candling, manual collection (or attach egg grader or separator) |

Operation Flow

Water bath loading Washing Drying Candling Manual packing (with UV sterilizing) Water bath loading

Pour the whole tray or box of eggs into a water bath, and eggs will be transported into washers in a single line that follows the conveyor. This loading method not only saves time but also minimizes egg cracks by using buoyancy. Plus, eggs are easier to wash after running through a water bath.

Washing Before washing After washing

Eggs are fully cleaned by brushes with warm water spraying. Brush modules are flexible, and adjustments can be made on brush distance, position and speed.

Drying

Eggs are perfectly dried by drying brush and strong air generated by drying fans.

CandlingWashed eggs will run through LED lights for candling purpose and workers can easily pick out any unqualified eggs such as leaking or cracking ones.

Manual packing (with UV sterilizing)Washed eggs will roll onto collection table and placed into trays or packed up manually, or can be attached with ZENYER /egg grader and ZENYER / / egg separator for assembly line.

Links:https://www.globefindpro.com/products/16345.html

-

301A Egg Processing Line with Cleaning & Grading (5000 EGGS/HOUR)

301A Egg Processing Line with Cleaning & Grading (5000 EGGS/HOUR)

-

303B Egg Processing Line with Cleaning & Grading (20000 EGGS/HOUR)

303B Egg Processing Line with Cleaning & Grading (20000 EGGS/HOUR)

-

300A Egg Processing Line with Cleaning & Grading (3000 EGGS/HOUR)

300A Egg Processing Line with Cleaning & Grading (3000 EGGS/HOUR)

-

402H Egg Printer, Egg Coder

402H Egg Printer, Egg Coder

-

604A Egg Accumulator

604A Egg Accumulator

-

Solar Water Pump System

Solar Water Pump System

-

201A Egg Washer (5000 EGGS/HOUR)

201A Egg Washer (5000 EGGS/HOUR)

-

302B Egg Processing Line with Cleaning & Grading (10000 EGGS/HOUR)

302B Egg Processing Line with Cleaning & Grading (10000 EGGS/HOUR)

-

403H Egg Printer, Egg Coder

403H Egg Printer, Egg Coder

-

401H Egg Printer, Egg Coder

401H Egg Printer, Egg Coder

-

501A Egg Breaking and Separating Machine (3000EGGS/HOUR)

501A Egg Breaking and Separating Machine (3000EGGS/HOUR)

-

302AS Egg Processing Line with Cleaning & Grading (10000 EGGS/HOUR)

302AS Egg Processing Line with Cleaning & Grading (10000 EGGS/HOUR)