Cemented Carbide Grinding Application

Cemented carbides are metal matrix composites made by powder metallurgy where hard carbides such as tungsten carbide (WC), titanium carbide (TiC) or tantalum carbide (TaC) are cemented into composites using tough binder metals such as cobalt and nickel. With a high hardness and excellent wear resistance, it is often difficult to grind cemented carbide into micro-sized particles, which is why ceramics with a high hardness are used as the grinding material. A water cooling system is added to quickly cool materials, thereby improving the grinding effect.

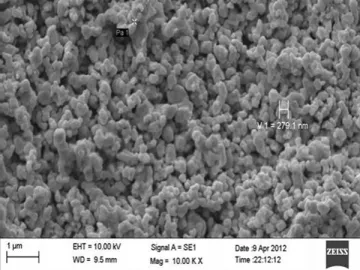

Shown below are comparison diagrams of several cemented carbides ground using our grinders. The cemented carbide particle size has been significantly reduced, and distribution is more uniform post grinding.

Grinding of tungsten carbide (WC)

Before grinding

After grinding

| Characterized size | Feed | Products |

| D50(μm) | 0.7 | 0.10 |

| D90(μm) | 1.1 | 0.25 |

Grinding of zirconium carbide (ZrC)

Before grinding

After grinding

| Grinding time | 0h | 2h | 12h |

| D50(μm) | 12.4 | 0.43 | 0.18 |

| D90(μm) | 37.3 | 0.68 | 0.35 |

Grinding of molybdenum carbide (MoC)

Before grinding

After grinding

After grinding

Before grinding

After grinding

After grinding

| Grinding time | 0h | 1h | 12h |

| D50(μm) | 2.86 | 0.42 | 0.12 |

| D90(μm) | 8.4 | 0.94 | 0.21 |

Grinding of titanium carbide (TiC)

Before grinding

After grinding

After grinding

Before grinding

After grinding

After grinding

| Grinding time | 0h | 2h | 8h |

| D50(μm) | 6.3 | 0.45 | 0.15 |

| D90(μm) | 50.2 | 0.69 | 0.22 |

Links:https://www.globefindpro.com/products/16381.html

-

On Grid Solar Power System

On Grid Solar Power System

-

LED Street Light

LED Street Light

-

TP Series Phase Failure Relay

TP Series Phase Failure Relay

-

Manual Override

Manual Override

-

APR-3 Series Phase Failure Relay

APR-3 Series Phase Failure Relay

-

TH-187/TH-188/TH-189 Mechanical Time Switches

TH-187/TH-188/TH-189 Mechanical Time Switches

-

Solar Power Systems, PV Energy Solution

Solar Power Systems, PV Energy Solution

-

Solar Lamp Posts

Solar Lamp Posts

-

Monocrystalline Solar Panel 60P, 280W-295W PV Module

Monocrystalline Solar Panel 60P, 280W-295W PV Module

-

Solar Light Traps

Solar Light Traps

-

Solar Powered Wireless Security Camera

Solar Powered Wireless Security Camera

-

Polycrystalline Solar Panel 72P, 305W-330W PV Module

Polycrystalline Solar Panel 72P, 305W-330W PV Module