Globe Valves Video

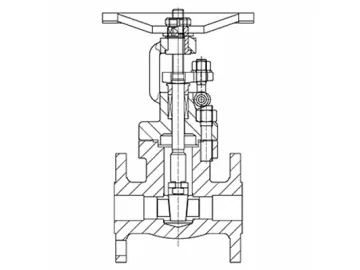

Pressure Seal Globe Valve

Globe Valve is a force seal valve, being widely used in nuclear power plants and petrochemical power plants, so pressure must be applied to the disc to prevent the sealing surface leakage when closing the valve.

For high temperature, high pressure and other harsh working conditions, our company has developed a new type of pressure seal globe valve: the higher the medium pressure, the better the sealing performance. In this new valve, the specific pressure between the packing box and the pressure seal gasket, as well as between the valve body and the pressure seal gasket, increases gradually with the increase of pressure by adjusting the structure design of the holdback bolt and floating packing box, so the sealing performance of the valve is better.

Design Features

Conical disc and flat disc

Full bore or reduced bore

Integral seat

Bolted bonnet or Pressure seal bonnet

Specification

Design standard: API, ASME, EN, ISO, JIS, DIN, BS, GB

Pressure rating: CLASS 150LB~2500LB, 1.0MPa~42.0MPa, JIS 10K~40K

Size range: NPS1/2” ~60”, DN15~DN1500

Standard connections: flange, threaded, butt weld, socket weld

Drive: handle, gear, pneumatic actuator, electric actuator

Samples

Pressure: 900LB

Size: 6”

Material: A494 CW12MW

Standard connections: flange RTJ

Applications: cyclohexanone transportation

Pressure: PN10

Size: DN400

Material: Titanium Gr.2

Standard connections: flange RTJ

Applications: metallurgy

Pressure: 600LB

Size: 2”

Material: Zirconium 702

Standard connections: flange RTJ

Applications: acetic acid transportation

Pressure: PN16

Size: DN65

Material: Nickel N6

Standard connections: flange RTJ

Applications: caustic soda transportation

Pressure: PN100

Size: DN40

Material: Monel M35-1

Standard connections: flange RTJ

Applications: hydrofluoric acid transportation

Pressure: 150LB

Size: 8”

Material: Super duplex 2507

Standard connections: flange RTJ

Applications: sea water desalination

Links:https://www.globefindpro.com/products/16524.html

-

ERW406 ERW Carbon Steel Tube Mill

ERW406 ERW Carbon Steel Tube Mill

-

ERW165 ERW Carbon Steel Tube Mill

ERW165 ERW Carbon Steel Tube Mill

-

ERW508 ERW Carbon Steel Tube Mill

ERW508 ERW Carbon Steel Tube Mill

-

ERW76 ERW Carbon Steel Tube Mill

ERW76 ERW Carbon Steel Tube Mill

-

Pipe Mill with ZTF Forming Process

Pipe Mill with ZTF Forming Process

-

LANDI Series High-speed Diesel Engines (450~1338kW)

LANDI Series High-speed Diesel Engines (450~1338kW)

-

WD Y Series High-speed Diesel Engine

WD Y Series High-speed Diesel Engine

-

Slurry Letdown And Vent Angle Control Valves Video

Slurry Letdown And Vent Angle Control Valves Video

-

Gate Valves

Gate Valves

-

ERW50 ERW Carbon Steel Tube Mill

ERW50 ERW Carbon Steel Tube Mill

-

WJ Series High-speed Diesel Engine

WJ Series High-speed Diesel Engine

-

ERW720 ERW Carbon Steel Tube Mill

ERW720 ERW Carbon Steel Tube Mill