Sound Attenuator

Sound attenuators are designed to reduce noise generated by fans and other equipment in industrial settings. The installation of a sound attenuator on the inlet or outlet of a ventilation system has been proven to reduce noise levels by as much as 10 to 40 dB(A) - and 50 to 93% drop in noise levels. Our sound attenuators are made of either carbon steel or stainless steel depending on customer requirements, and feature a small size, silent performance, light weight, and easy installation. They are widely used in power generation, chemical, metallurgical, and textile industries.

Quanda provides customized sound attenuators to meet unique customer requirements.

This regular sound attenuator is designed to reduce noise in medium and low-pressure fans in air conditioning systems and heat ventilation systems with a silencing effect per unit length as follows: 10~15dB for low frequency, 10~25db for medium frequency, and 25~30db for high frequency. Its average drag coefficient is 0.4, making it ideal for the place where wind speed is 6-12m/s (mm).

Specifications| No | Size(mm) | Length(mm) | Effective Cross-sectional Area (m2) | Expansion Ratio (M) | Effective Cross-Sectional Frequency (Hz) | Applicable Air Volume (mm³/h) | ||||

| A×B | a×b | Velocity 6m/s | Velocity 8m/s | Velocity 10m/s | Velocity 12m/s | |||||

| 1 | 800×500 | 520×230 | 1600 | 0.093 | 4.26 | 596 | 2000 | 2660 | 3330 | 4000 |

| 2 | 800×600 | 510×370 | 1600 | 0.139 | 3.91 | 507 | 3000 | 4000 | 5000 | 6000 |

| 3 | 1000×600 | 700×370 | 1600 | 0.186 | 3.17 | 480 | 4000 | 5330 | 6670 | 8000 |

| 4 | 1000×800 | 770×400 | 1600 | 0.231 | 3.46 | 420 | 5000 | 6660 | 8320 | 10000 |

| 5 | 1200×800 | 700×550 | 900 | 0.278 | 3.43 | 380 | 6000 | 8000 | 10000 | 12000 |

| 6 | 1200×1000 | 780×630 | 900 | 0.372 | 3.20 | 339 | 8000 | 10660 | 13340 | 16000 |

| 7 | 1500×1000 | 950×630 | 900 | 0.463 | 3.29 | 430 | 10000 | 13320 | 16640 | 20000 |

| 8 | 1500×1400 | 1000×970 | 900 | 0.695 | 3.70 | 513 | 15000 | 2000 | 25000 | 30000 |

| 9 | 1800×1400 | 1300×970 | 900 | 0.928 | 2.73 | 470 | 20000 | 26700 | 33400 | 40000 |

| 10 | 2000×1800 | 1500×1310 | 900 | 1.390 | 2.59 | 393 | 30000 | 40000 | 50000 | 60000 |

Rectangular duct silencers use porous sound absorption materials in airflow ducts to attenuate sound waves for a noise reduction. The friction between acoustic energy and porous sound absorbing materials converts the acoustic energy into heat.

| Serial | The noise reduction at the octave center frequency (dB) | Size(mm) | Weight(KG) | |||||||||

| 100 | 200 | 400 | 800 | 1600 | 3150 | 6300 | a | b | A | B | ||

| Extra-fine glass wool sound attenuator QD-ZG | ||||||||||||

| 1 | 7.7 | 15 | 20.8 | 23.4 | 26.2 | 27.2 | 18.0 | 300 | 300 | 200 | 200 | 32.9 |

| 2 | 6.4 | 12.5 | 17.3 | 19.4 | 21.8 | 14.6 | 7.2 | 300 | 400 | 200 | 300 | 38.9 |

| 3 | 5.8 | 11.3 | 15.6 | 17.5 | 19.7 | 13.2 | 6.6 | 300 | 500 | 200 | 400 | 44.8 |

| 4 | 6.2 | 12 | 16.6 | 18.8 | 21 | 14.0 | 7.0 | 350 | 350 | 250 | 250 | 38.1 |

| 5 | 5.1 | 10 | 13.9 | 15.6 | 17.5 | 12.0 | 6.0 | 350 | 475 | 250 | 375 | 46.5 |

| 6 | 4.6 | 9 | 12.5 | 14 | 15.8 | 10.5 | 5.3 | 350 | 600 | 250 | 500 | 53.9 |

| 7 | 5.1 | 10 | 13.9 | 15.6 | 17.5 | 11.7 | 5.8 | 400 | 400 | 300 | 300 | 44.8 |

| 8 | 4.2 | 8.3 | 11.6 | 12.9 | 14.6 | 9.7 | 4.9 | 400 | 550 | 300 | 450 | 53.9 |

| 9 | 3.8 | 7.5 | 10.4 | 11.7 | 13.2 | 8.8 | 4.4 | 400 | 700 | 300 | 600 | 62.8 |

The duct silencer is equipped with sound-absorption sheets and installed inside large-scale air ducts. These sound-absorbing sheets form several flat muffler channels, which is why the duct silencer is also called a tubular type silencer. Quanda provides sound-absorbing sheets in a variety of thicknesses, including 50, 100, and 200mm. These sound absorbing sheets are suitable for ductwork with air volume ranges of 750m³/H to 80000m³/H.

QD-SWX Sound AttenuatorThis sound attenuator features a double-wall structure and outstanding silencing effect. The broadband sound absorption is more than 1/3 octave bands, making this sound attenuator ideal for ductwork that needs to be moisture and high temperature resistant. For customers with added requirements for degree of cleanliness, we will also customize the sound attenuator, ensuring it is manufactured in accordance with customer provided design drawings.

YXSQ Sound AttenuatorThis sound attenuator is equipped with a cross sound-absorption sheet within the cross-sectional area to increase the noise reduction performance and rigidity.

| Model | Size d×L(mm) | Flange Length D(mm) | Airflow m3/h | Insertion loss Pa | Noise Reduction dB(A) | Model | Size d×L(mm) | Flange Length D(mm) | Airflow m3/h | Insertion loss Pa | Noise Reduction dB(A) |

| 1 | 320×1100 | 200 | 670~890 | 5.9 | 15~20 | 5 | 440×1100 | 320 | 1720~2290 | 5.9 | 15~20 |

| 2 | 340×1100 | 220 | 810~1080 | 5.9 | 15~20 | 6 | 480×1100 | 360 | 2180~2910 | 5.9 | 15~20 |

| 3 | 370×1100 | 250 | 1050~1400 | 5.9 | 15~20 | 7 | 520×1100 | 400 | 2690~3590 | 5.9 | 15~20 |

| 4 | 400×1100 | 280 | 1320~1750 | 5.9 | 15~20 | 8 | 570×1100 | 450 | 3410~4550 | 5.9 | 15~20 |

| Length (mm) | Air Velocity (m/s) | Static Pressure Loss (mmH2O) | Noise Reduction (dB) in the Frequency (Hz) | |||||

| 125 | 250 | 500 | 1000 | 2000 | 4000 | |||

| 900 (one section) | 8 | 3.8 | 7.0 | 14.0 | 18.0 | 19.5 | 24.0 | 25.5 |

| 6 | 1.0 | 7.0 | 14.3 | 20.0 | 20.7 | 25.5 | 25.3 | |

| 4 | 0.4 | 7.5 | 14.5 | 22.0 | 21.7 | 27.0 | 28.0 | |

| 1800 (two sections) | 8 | 5.2 | 11.0 | 22.3 | 31.0 | 32.2 | 39.7 | 40.9 |

| 6 | 2.8 | 12.6 | 25.5 | 35.4 | 36.8 | 45.3 | 41 | |

| 4 | 1.4 | 13.4 | 27.0 | 37.6 | 39.1 | 48.2 | 49.7 | |

| 2700 (three sections) | 8 | 7.0 | 13.2 | 26.8 | 37.2 | 38.6 | 47.6 | 49.1 |

| 6 | 3.2 | 15.9 | 32.2 | 44.7 | 46.5 | 57.2 | 59.0 | |

| 4 | 1.9 | 17.2 | 34.9 | 48.4 | 50.4 | 62.1 | 54.0 | |

This sound attenuator features perforated sound absorbing acoustic panels filled with an extra-fine glass wool inside the inner wall for a noise reduction performance.

| Model ZXW-I | Size | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| A×B(mm) | 320×200 | 320×250 | 320×320 | 400×200 | 400×250 | 400×320 | 400×400 | |

| Size | 8 | 9 | 10 | 11 | - | - | - | |

| A×B(mm) | 500×200 | 500×250 | 500×320 | 500×400 | - | - | - | |

| Model ZXW-II | Size | 12 | 13 | 14 | 15 | 16 | 17 | 18 |

| A×B(mm) | 630×200 | 630×400 | 630×500 | 630×630 | 800×320 | 800×400 | 800×500 | |

| Size | 19 | 20 | 21 | 22 | 23 | 24 | 25 | |

| A×B(mm) | 800×630 | 800×800 | 1000×400 | 1000×500 | 1000×630 | 1000×800 | 1000×1000 | |

| Model ZXW-III | Size | 26 | 27 | 28 | 29 | 30 | 31 | 32 |

| A×B(mm) | 1250×400 | 1250×500 | 1250×630 | 1250×800 | 1250×1000 | 1600×500 | 1600×630 | |

| Size | 33 | 34 | 35 | 36 | 37 | 38 | 39 | |

| A×B(mm) | 1600×800 | 1600×1000 | 1600×1250 | 2000×630 | 2000×800 | 2000×1000 | 2000×1250 |

Sound absorption material inside this sound attenuator is glass wool wrapped in a glass cloth and a galvanized orifice plate lining. This high-performance sound attenuator is often used in air inlets and outlets of ventilation and air conditioning systems to effectively reduce dynamic pressure, increase static pressure, and stabilize the airflow.

XBYC Sound AttenuatorThis sound attenuator is designed for noise reduction in service rooms without affecting ventilation. It will also reduce outdoor interference for server rooms. It is made of a high-quality galvanized steel, aluminum alloy, or stainless steel according to customer requirements, and uses a small, elliptical shaped wing sound absorption sheet for noise reduction. The sound attenuator is widely used in ventilation systems for service rooms, hotels, hospitals, and other areas.

Specifications| Thickness of Sound Attenuator (mm) | Size (W×H) | Noise Reduction (dB) in the Frequency (Hz) | |||||

| 125 | 250 | 500 | 1000 | 2000 | 4000 | ||

| 300 | 300×600 | 10.0 | 11.0 | 12.0 | 15.0 | 19.0 | 20.0 |

| 600×800 | 10.1 | 11.2 | 12.1 | 15.2 | 19.2 | 20.1 | |

| 900×1000 | 10.2 | 11.3 | 12.2 | 15.3 | 19.4 | 20.3 | |

| 900×1200 | 10.3 | 11.5 | 12.3 | 15.5 | 19.5 | 20.4 | |

| 1200×1200 | 10.5 | 11.7 | 12.5 | 15.6 | 19.7 | 20.5 | |

| 1200×2000 | 10.8 | 11.9 | 12.8 | 15.8 | 19.8 | 20.7 | |

Links:https://www.globefindpro.com/products/16885.html

-

T35-11 Series Direct Drive Axial Flow Fan

T35-11 Series Direct Drive Axial Flow Fan

-

QD-LFK9 Aluminum Egg Crate Grille

QD-LFK9 Aluminum Egg Crate Grille

-

QD-LFK7 Aluminum Square Diffuser

QD-LFK7 Aluminum Square Diffuser

-

FPB Series Vaneaxial Adjustable Pitch Fan

FPB Series Vaneaxial Adjustable Pitch Fan

-

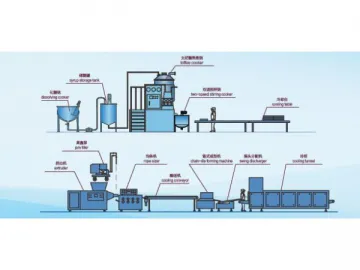

Sheet Type Gum Production Line

Sheet Type Gum Production Line

-

DWT Series Roof Exhauster

DWT Series Roof Exhauster

-

QDKH Backward Curved Square Duct Blower

QDKH Backward Curved Square Duct Blower

-

QD-DFL Series Positive Pressure Damper

QD-DFL Series Positive Pressure Damper

-

QDPF Square Inline Duct Fan

QDPF Square Inline Duct Fan

-

QD-DFL Series Rectangular Constant Air Volume Damper

QD-DFL Series Rectangular Constant Air Volume Damper

-

Die-Formed Toffee Candy Production Line

Die-Formed Toffee Candy Production Line

-

Gum Ball Production Line

Gum Ball Production Line