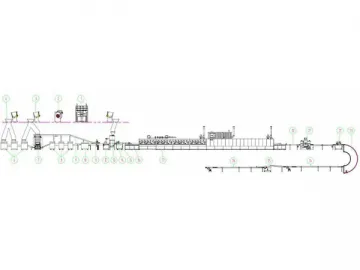

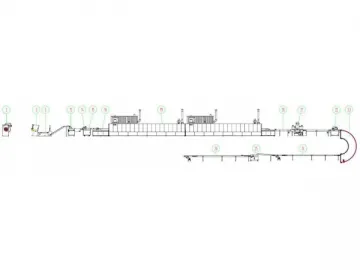

Die-Formed Hard Candy Production Line

With a maximum output capacity of 400kg/h of hard candy, this die-formed hard candy production line is designed to produce various shapes of candies utilizing different molds. The electric heating cooker precisely controls the heating time and temperature which results in candy that is more transparent and flavorful. The production line is equipped with an advanced hard candy former that effectively ensures size consistency and minimizes material waste.

The entire production line is produced in a manner that meets GMP and food hygiene requirements. This will make it easier for your company to pass various certifications including GMP, QS, HACCP, etc.

Sugar dissolving cooker Liquid glucose storage Continuous vacuum cooker Cold table Batch roller Rope sizer Die forming machine Shaking distribution conveyor Refrigerated cooler Features The electric heating vacuum cooker can be used to produce high-quality syrup. The candy sticks are rapidly punch extruded Its capacity reaches up to 300-400kg per hour. This production line can produce various shapes of hard candies by simply changing the molds. The cooling conveyor system provides the good cooling effects. If combined with an automatic sucker stick insert machine, the production line can be applied to produce suckers. StandardContinuous vacuum cooker

It features automatic temperature control, high output, time-saving, short cooking time, and can manufacture the syrup with high transparency.

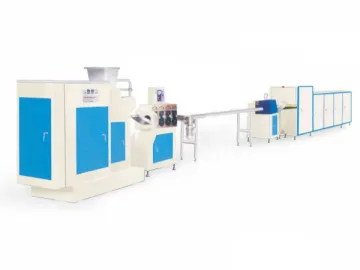

Forming machine

The forming machine is designed to manufacture hard candies with a variety of specifications and shapes.

Optional

Extruder

The extruder enables the production line to manufacture filled hard candies.

Kneading and cooling machine

This machine fully mixes the syrups with various flavours to ensure the candy is delicious.

Production Line Recommendations

YT200L die-formed hard candy production line

The production line provides cost-effective performance for small-scale candy plants as its capacity is 100-200kg/h.

YT400L automatic die-formed hard candy production line

This automatic production line is equipped with a vacuum cooker which can effectively reduce the temperature of the syrup and make it more transparent so as to improve its quality and taste.

Links:https://www.globefindpro.com/products/16909.html

-

Flow Amplifier ZLF25E

Flow Amplifier ZLF25E

-

Limit Valve XF-B6

Limit Valve XF-B6

-

Unloading Valve PDV25

Unloading Valve PDV25

-

Multifunction Biscuit Production Line

Multifunction Biscuit Production Line

-

SF8 Pressure Selector Valve

SF8 Pressure Selector Valve

-

Gummy Production Line by US Customer

Gummy Production Line by US Customer

-

Central-Filled Soft Chewy Candy Production Line

Central-Filled Soft Chewy Candy Production Line

-

Flow Diverter Valve LZF20

Flow Diverter Valve LZF20

-

Toffee Candy Production Line by Egypt Customer

Toffee Candy Production Line by Egypt Customer

-

Gummy Candy Depositing Production Line, GD150Q

Gummy Candy Depositing Production Line, GD150Q

-

Handmade Marshmallow Depositing Machine

Handmade Marshmallow Depositing Machine

-

Soft Biscuit Production Line

Soft Biscuit Production Line