Automatic Linear Capping Machine, FGX-1A/2A (Automatic Press Snap Capping Machine)

FXG-1A/2A fully automatic linear capping machine is made up of unscrambler, conveyor, gripping and capping system, motion control system, etc. The automatic capping machine features compact construction, easy operation and adjustment, which is suitable for automatic capping of 1-5L bottles. This is one of the most recently developed machine model by our company. The capping process will be completed during moving the bottles. The normal machine needs to pause when performing capping operation, so that the liquid will not shake out from the bottle to pollute the bottles' body. Therefore, this newly developed automatic capping machine has higher working efficiency in comparison to the normal model.

| Type | FGX-1A | FGX-2A |

| Capping head number | 1 Capping head | 2 Capping heads |

| Capacity | ≤3000 bottles/hour | ≤5000 bottles/hour |

| Cap feeding system | Cap pick-off system with a precise chute | |

| Pass rate | ≥99% | |

| Applicable bottle type | Round bottle: ⌀ 50-140mm, height: 230-340mm Flat bottle: length 45-250mm, width45-140mm, height 90-340mm | |

| Cap specification | ⌀ 30-65mm, H15-30mm | |

| Air pressure | 0.6~0.8MPa | |

| Power supply | 380V, 50Hz / 60Hz | |

| Power | 2.5kW | 3kW |

| Machine weight | 1100kg | 1300kg |

| Machine dimensions | 2195×1300×2300mm (L×W×H) | |

Machine details

The automatic capping machine comes with a modular construction. Each module has the advantages of quick installation and removal, which greatly saves maintenance and repair time.

Links:https://www.globefindpro.com/products/1730.html

-

Paper Machine Rolls

Paper Machine Rolls

-

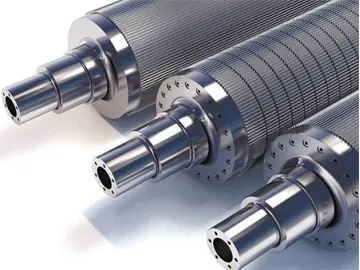

Corrugating Rolls

Corrugating Rolls

-

Press Felts for Paper Machine

Press Felts for Paper Machine

-

Corrugated Slitter Knives & Grinding Wheels

Corrugated Slitter Knives & Grinding Wheels

-

Glue Machine for corrugated cardboard production

Glue Machine for corrugated cardboard production

-

Automatic Screw Capping Machine (for Pour Spouts of Laundry Detergent Bottle), FYG-1/2

Automatic Screw Capping Machine (for Pour Spouts of Laundry Detergent Bottle), FYG-1/2

-

Mill Roll Stand

Mill Roll Stand

-

High Speed Pulp Washer

High Speed Pulp Washer

-

Headbox for Paper Machine

Headbox for Paper Machine

-

Prefabricated Commercial Building, Comfort Series

Prefabricated Commercial Building, Comfort Series

-

Paper Pulp Pumps

Paper Pulp Pumps

-

Prefabricated Sunroom, 48 Series

Prefabricated Sunroom, 48 Series