Double Facer for corrugated cardboard production

Double facer is a major unit in corrugated cardboard production line. It is mainly designed for bonding, heating, drying and cooling of the single faced corrugated cardboard and paper, thus to produce quality three, five or seven layered corrugated cardboard. Besides, it also feeds corrugated cardboard to slitter scorer and other machines for further processing.

| Working Width | 1000-2500 mm |

| Steam Pressure | 0.8-1.3 Mpa |

| Air Pressure | 0.6-0.9 Mpa |

| Up Drive Roller Diameter | 400/600/800 mm |

| Down Drive Roller Diameter | 400/600/600 mm |

paper corrugation machine

corrugated board production

cardboard machinery

Scan QR to Read

Links:https://www.globefindpro.com/products/1757.html

Links:https://www.globefindpro.com/products/1757.html

Recommended Products

-

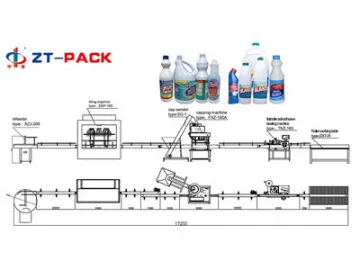

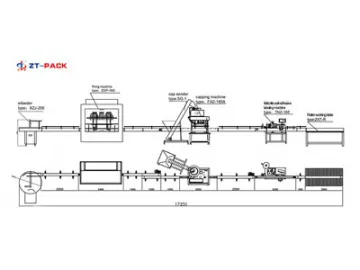

50ml -5000ml Bleach Acid Corrosive Liquid Filling Line

50ml -5000ml Bleach Acid Corrosive Liquid Filling Line

-

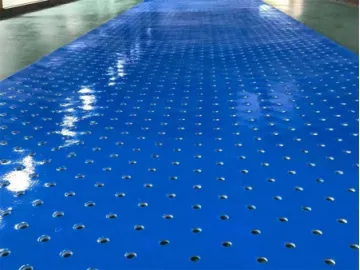

No-Crush Wheels

No-Crush Wheels

-

Corrugator Auto Splicer

Corrugator Auto Splicer

-

Automatic Shrink Bundler (Shrink Wrap and Bundling System), SB-15B

Automatic Shrink Bundler (Shrink Wrap and Bundling System), SB-15B

-

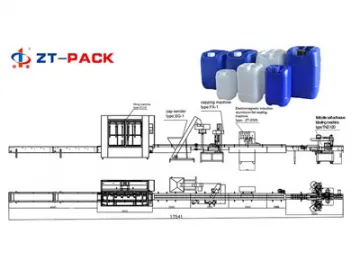

4L-30L Drum Gallons Edible Oil Filling Line

4L-30L Drum Gallons Edible Oil Filling Line

-

5L-20L Drum Gallons Filling Line (Corrosive Liquids Packing)

5L-20L Drum Gallons Filling Line (Corrosive Liquids Packing)

-

Single Facer for corrugated cardboard production

Single Facer for corrugated cardboard production

-

NC-Cut Off Machine

NC-Cut Off Machine

-

100ml-1000mL Engine Oil Filling Line

100ml-1000mL Engine Oil Filling Line

-

Corrugator Belt

Corrugator Belt

-

Slitter Scorer for corrugated cardboard production

Slitter Scorer for corrugated cardboard production

-

Corrugated Cut Off Knives

Corrugated Cut Off Knives