CNC Turning Center, Horizontal CNC Lathe

Our CNC lathes make it easy to process high-precision parts in large quantities. The high-quality cast iron is adopted as the raw material for the bed, leading to a good rigidity and a maximum absorption of vibration to ensure machining accuracy. Moreover, the machine is equipped with a four-station tool holder that can meet the needs of automatic tool change during cutting, which is able to complete turning in a variety of processes.

JC Machinery is committed to provide reliable and effective CNC lathes for customers to maintain highly efficient production. In addition to CNC lathes, we also provide manual lathes to meet different needs of customers. All the equipment is offered a one-year warranty and lifetime technical support.

Parameters

| Model | Unit | JC-6140/750 | JC-C6150/1000 | JC-C6163/1000 |

| Processing range | ||||

| Max. swing over bed | Mm | 420 | 500 | 630 |

| Max. swing over cross slide | Mm | 200 | 300 | 320 |

| Diameter of spindle bore | Mm | 52 | 62 | 62 |

| Distance between centers | Mm | 750 | 1000 | 1000 |

| Max. turning length | Mm | 550 | 750 | 750 |

| Travel | ||||

| X-axis travel | Mm | 220 | 260 | 260 |

| Z-axis travel | Mm | 550 | 750 | 750 |

| Spindle | ||||

| Max. spindle speed | Rpm | 50-2500 | Three gears of 30-1600, stepless in gear 50-2200 | Three gears of 30-1600, stepless in gear 50-2200 |

| Type of main spindle head and taper | M16 | M18 | M18 | |

| Chuck size | Mm | 250 | 250 | 250 |

| Automatic tool changer | ||||

| Tool turret station | PCS | 4/6/8 | 4/6/8 | 4/6/8 |

| Size of tool holder | M | 20*20 | 25*25 | 25*25 |

| Tailstock | ||||

| Diameter of tailstock quill | MT-5 | MT-5 | MT-5 | |

| Travel of tailstock quill | Mm | 130 | 150 | 150 |

| Taper of tailstock quill | Mchs | 4 | 5 | 5 |

| Motor | ||||

| Spindle motor power | Kw | 505 | 7.5 | 7.5 |

| Accuracy | ||||

| X/Z-axis positioning accuracy | Mm | ±0.008 | ±0.010 | ±0.010 |

| X/Z-axis repeatability accuracy | Mm | ±0.005 | ±0.008 | ±0.008 |

| X/Z-axis rapid speed | Mm | 6/8 | 6/8 | 6/8 |

| Machine information | ||||

| Machine dimension | Mm | 2310*1360*1570 | 2570*1410*1650 | 2570*1411*1650 |

| Machine weight | Kg | 2000 | 2300/2500 | 2800/3000 |

| Power demand | Kw/A | 10/22 | 12/24 | 12/24 |

The guide rail is of high precision due to the precise grinding after quenching treatment.

The CNC lathes are of high safety protection level thanks to the fully enclosed sheet metal protection.

The operation interface is in front of the machine and is flush with the operator’s sight line, which is very convenient for the operator to work.

Different operating systems can be selected according to customer needs to meet the operating habits of different operators.

Scan QR to Read

Links:https://www.globefindpro.com/products/17793.html

Links:https://www.globefindpro.com/products/17793.html

Recommended Products

-

ALU-M004 Aluminum Hookah, 52cm Complete Set Hookah

ALU-M004 Aluminum Hookah, 52cm Complete Set Hookah

-

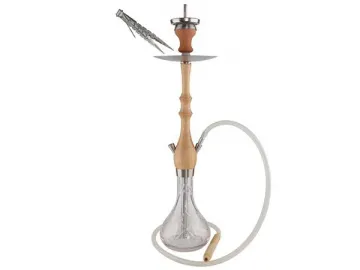

WOOD-B004 Wooden Hookah, 83cm Complete Set Hookah

WOOD-B004 Wooden Hookah, 83cm Complete Set Hookah

-

SP-M001 Stainless Steel Hookah, 34cm Tall Mini Hookah

SP-M001 Stainless Steel Hookah, 34cm Tall Mini Hookah

-

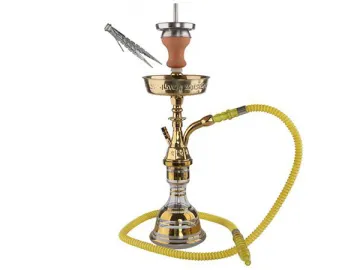

WOOD-B002 Wooden Hookah, 79cm Complete Set Hookah

WOOD-B002 Wooden Hookah, 79cm Complete Set Hookah

-

WOOD-B003 Wooden Hookah, 72cm Complete Set Hookah

WOOD-B003 Wooden Hookah, 72cm Complete Set Hookah

-

SS-MINI001 Stainless Steel Hookah, 30cm Tall Mini Hookah

SS-MINI001 Stainless Steel Hookah, 30cm Tall Mini Hookah

-

Z-M001 Zinc Alloy Hookah, 64cm Complete Set Hookah

Z-M001 Zinc Alloy Hookah, 64cm Complete Set Hookah

-

SS-M001 Stainless Steel Hookah, 61cm Complete Set Hookah

SS-M001 Stainless Steel Hookah, 61cm Complete Set Hookah

-

Tool Roll

Tool Roll

-

SS-B002 Stainless Steel Hookah, 63cm Complete Set Hookah

SS-B002 Stainless Steel Hookah, 63cm Complete Set Hookah

-

Tool Belt

Tool Belt

-

Tool Apron

Tool Apron

Hot Products