Sinker EDM, Sinker Electric Discharge Machining

Sinker electric discharge machining (sinker EDM) equipment is mainly applied in the processing of precision molds and parts. Some components will require sinker EDM processing if rough details are left after previous machining operations.

Parameters

| Model | Unit | JC350 | JC450 | JC540 | JC650 |

| X/Y/Z-axis travel | mm | 350/250/200 | 450/350/200 | 500/400/250 | 600/500/280 |

| Machining head travel | mm | 200 | 200 | 300 | 300 |

| Distance from electrode head surface to work table surface | mm | 400 | 580 | 650 | 830 |

| Worktable size(L×W) | mm | 600×350 | 700×400 | 800×500 | 1000×600 |

| Size of oil bath on work table (L×W×H) | 900×500×400 | 1370×670×450 | 1400×700×500 | 1800×1100×600 | |

| Max. load on work table | Kg | 800 | 1000 | 1500 | 2500 |

| Max. weight of electrode | Kg | 120 | 150 | 150 | 220 |

| Max. oil level in oil bath | 300 | 370 | 370 | 470 | |

| Oil tank capacity | L | 350 | 370 | 540 | 1120 |

| Size of oil tank(L×W×H) | mm | 1300×920×450 | 1250×780×480 | 1400×900×450 | 2000×1250×500 |

| Machine power | KVA | 5 | 5 | 5 | 7.5 |

| Packing dimensions of machine(L×W×H) | mm | 1460×1500×2245 | 1750×2000×2250 | 1850×2000×2350 | 2100×2100×2700 |

| Packing weight of machine | Kg | 1500 | 2000 | 2500 | 3000 |

| Packing dimensions of control cabinet(L×W×H) | mm | 870×860×2100 | |||

| Packing weight of control cabinet | Kg | 260 |

Features

Large-size touch screen is easy for operators to set parameters.

There will be no deformation of work table after high frequency heat treatment.

The ball screw on X-Y axes brings flexible transmission and high accuracy, with an error less than 0.01mm.

The spindle feeding has the function of stepless gear shifting.

The auto-stop function enables the machine to shut down automatically when the machining is completed.

The power-off memory function allows the machine to start processing automatically after power restoration.

There are protection functions such as power failure alarm, anti-collision and timing switcher.

Standard Configuration

Oil filter

Control cabinet

Water tank with strainer

Tool cabinet

Optional Configuration

Orbiting head

magnetic chuck

Spark erosion oil

Scan QR to Read

Links:https://www.globefindpro.com/products/17855.html

Links:https://www.globefindpro.com/products/17855.html

Recommended Products

-

Swivels and Accessory

Swivels and Accessory

-

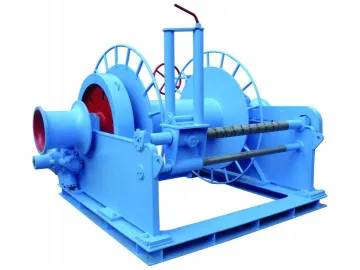

Hydraulic vertical capstan

Hydraulic vertical capstan

-

Shipboard Cranes

Shipboard Cranes

-

Hydraulic Anchor Windlass

Hydraulic Anchor Windlass

-

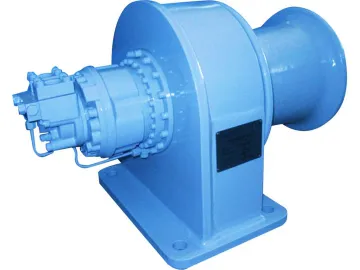

Horizontal Capstan

Horizontal Capstan

-

Light Purse Seine

Light Purse Seine

-

Front Roller

Front Roller

-

Hole Drilling EDM, Hole Electric Discharge Machining, EDM Drilling Machine

Hole Drilling EDM, Hole Electric Discharge Machining, EDM Drilling Machine

-

Sea Anchor Float

Sea Anchor Float

-

Squid Entrails Removal Tool

Squid Entrails Removal Tool

-

Hall Sensor

Hall Sensor

-

Lamp holder for underwater halogen lamp

Lamp holder for underwater halogen lamp