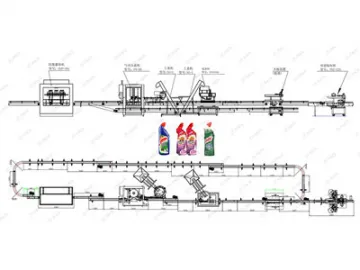

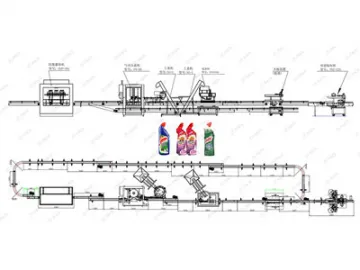

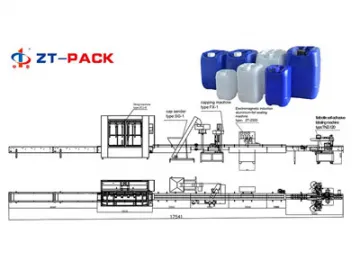

100ml-1000ml Corrosive Liquid Filling Line (Harpic Toilet Cleaner Packaging)

Suitable bottles Suitable for filling: Toilet cleaner, harpic acid, etc. Filling range: 100ml-1000ml Bottle type: Duck-shaped neck bottle type Numbers of filling nozzles: 6-16 Capacity: 1000BPH-4000BPH Filling system: Gravity & piston Accuracy: 1%  Features of Control Box Independent electrical box 2-3 meters far away from the main machine to avoid electrical part damage caused by spilled liquids Siemens control system Remote control from China on the machines around the world Made using PVC plastic material IP65 protection rating Air pressure control system Specifications

Features of Control Box Independent electrical box 2-3 meters far away from the main machine to avoid electrical part damage caused by spilled liquids Siemens control system Remote control from China on the machines around the world Made using PVC plastic material IP65 protection rating Air pressure control system Specifications

Details

Automatically complete bottle unscramble, filling, capping, sealing, labeling, QR code, unpacking, packing, sealing, and palletizing, equipped with an integrated environmental protection cover. It conforms to the standards of safety, environmental protection and intelligent three-levelization, and the production process is automatically coordinated, which is stable and efficient.

| Model | ZGP-6G | ZGP-8G | ZGP-10G | ZGP-12G | ZGP-16G |

| Dimensions | 2000 (L)x710 (W)x2200(H) mm | 2200(L)x710(W)x2200(H) mm | 2300 (L)x710 (W)x2200(H) mm | ||

| Filling head | 6 | 8 | 10 | 12 | 16 |

| Capacity (500 mL) | 1500B/H | 2000B/H | 2500B/H | 3000B/H | 4000B/H |

| Power | 1kW | 1 kW | 1 kW | 1.5 kW | 1.5 kW |

| Suitable bottle | Diameter: ⌀ 40mm - ⌀ 100mm, height: 80mm-280mm | ||||

| Filling accuracy | ≤100ml: ±1.5ml 100-500ml: ±2ml 500-1000ml: ±3ml | ||||

| Neck diameter | ≤⌀10mm (can be designed accordingly) | ||||

| Filling range | 100ml-1000ml | ||||

| Air pressure | 0.6Mpa | ||||

| Power supply | 220V, 50Hz/60Hz | ||||

Scan QR to Read

Links:https://www.globefindpro.com/products/1789.html

Links:https://www.globefindpro.com/products/1789.html

Recommended Products

-

1L-5L Agrochemicals Filling Line

1L-5L Agrochemicals Filling Line

-

50ml -1000ml Pesticide Filling Line

50ml -1000ml Pesticide Filling Line

-

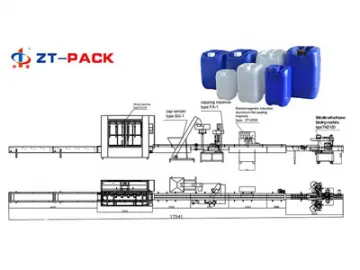

4L-30L Drum Gallons Engine Oil Filling Line

4L-30L Drum Gallons Engine Oil Filling Line

-

Fresh Noodle Machines

Fresh Noodle Machines

-

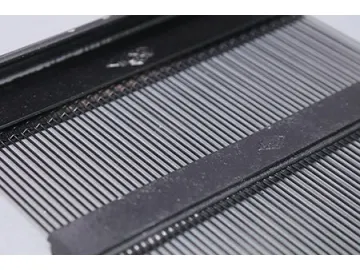

Self-Cleaning Piano Wire Screen

Self-Cleaning Piano Wire Screen

-

Anti-twisting Galvanized Steel Wire Rope (Pilot Wire Rope)

Anti-twisting Galvanized Steel Wire Rope (Pilot Wire Rope)

-

Vacuum Capping Machine, FDB

Vacuum Capping Machine, FDB

-

Polyurethane Screen

Polyurethane Screen

-

0.5L-7L Engine Oil Filling Line

0.5L-7L Engine Oil Filling Line

-

Soya Sauce Vinegar Filling Line

Soya Sauce Vinegar Filling Line

-

4L-30L Drum Gallons Liquid Filling Line

4L-30L Drum Gallons Liquid Filling Line

-

Perforated Plate Screen

Perforated Plate Screen