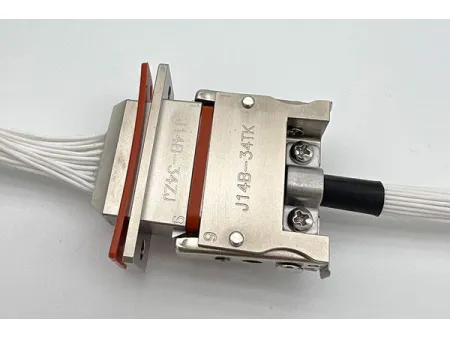

Circular Connectors (Military Connector)

MIL-C-26482 I Series Applications of Circular Connectors  MS3112P12-10S 85106RC18-32S50 General Information Compliant with MIL-C-26482 I series standards Bayonet coupling quick connect mechanism Contact configuration: mostly solder-type Compact size with high contact density Widely used in various military and civilian equipment Main Technical Performance Mechanical Performance Shell material: Aluminum alloy Plating options: Unmarked: Olive drab cadmium plating, conductive shell Class L: Chemical nickel plating, conductive shell Class A: Black anodization, non-conductive shell Class B: Cadmium plating, conductive shell Class S: Stainless steel passivation, conductive shell Class BW: Cadmium plating, brownish-green color, conductive shell Insulator material: Thermosetting or thermoplastic Sealing material: Silicone rubber Contact material: Gold-plated copper alloy Mechanical lifespan: 500 mating cycles Shock resistance: Withstands acceleration up to 490m/s² Random vibration resistance: Frequency range of 10-2000Hz, acceleration of 147m/s² Electrical Performance Working voltage and withstanding voltage (V):

MS3112P12-10S 85106RC18-32S50 General Information Compliant with MIL-C-26482 I series standards Bayonet coupling quick connect mechanism Contact configuration: mostly solder-type Compact size with high contact density Widely used in various military and civilian equipment Main Technical Performance Mechanical Performance Shell material: Aluminum alloy Plating options: Unmarked: Olive drab cadmium plating, conductive shell Class L: Chemical nickel plating, conductive shell Class A: Black anodization, non-conductive shell Class B: Cadmium plating, conductive shell Class S: Stainless steel passivation, conductive shell Class BW: Cadmium plating, brownish-green color, conductive shell Insulator material: Thermosetting or thermoplastic Sealing material: Silicone rubber Contact material: Gold-plated copper alloy Mechanical lifespan: 500 mating cycles Shock resistance: Withstands acceleration up to 490m/s² Random vibration resistance: Frequency range of 10-2000Hz, acceleration of 147m/s² Electrical Performance Working voltage and withstanding voltage (V):

Our MIL-C-26482 I series connectors are ideal for circuit signal connections.

EnvironmentsOur MIL-C-26482 I series connectors are suitable for a wide range of military and civilian equipment, ensuring reliable electrical connections in various demanding environments featuring high humidity, salt spray, fungi, heavy rain, and dust.

| Service rating | Withstanding voltage | Withstanding voltage | ||

| I | II | I | II | |

| Sea level | 600 | 1000 | 1500 | 2300 |

| 21336m | 300 | 450 | 375 | 500 |

Note: Different contact arrangements have different operating levels, see top-right corner of contact arrangement label

Contact resistance and current rating:| Contact ID | Diameter (mm) | Resistance (mΩ) | Current (A) |

| 20# | Ø1.00 | ≤5 | 7.5 |

| 16# | Ø1.60 | ≤2.5 | 13 |

| 12# | Ø2.40 | ≤1.5 | 23 |

Insulation resistance: ≥ 5000MΩ at 25˚C, and ≥ 3MΩ at 125˚C

Environmental Performance Operating temperature: -55°C to 125°C Relative humidity: 95±4% at 40°C Salt spray test results: Cadmium plating: 500 hours Nickel plating: 48 hours/96 hours Sealing: Wire sealing: Pressure difference of 2×105Pa, leakage rate less than 4.6×102Pa•cm³/s Sintered sealing: Pressure difference of 1×105Pa, leakage rate less than 0.1Pa•cm³/s

Scan QR to Read

Links:https://www.globefindpro.com/products/186.html

Links:https://www.globefindpro.com/products/186.html

Recommended Products

-

Circular Connectors

Circular Connectors

-

Shank Adapters

Shank Adapters

-

Circular Connectors (Military Connector)

Circular Connectors (Military Connector)

-

Circular Connectors (Military Connector)

Circular Connectors (Military Connector)

-

Automatic Edge Taping Machine

Automatic Edge Taping Machine

-

Shank Rods

Shank Rods

-

MF Rods / Male-Female Drill Rods

MF Rods / Male-Female Drill Rods

-

Tapered Drill Bits

Tapered Drill Bits

-

Threaded Button Bits

Threaded Button Bits

-

Rectangular Connectors

Rectangular Connectors

-

Circular Connectors (Military Connector)

Circular Connectors (Military Connector)

-

Extension Rods / MM Rods

Extension Rods / MM Rods