Circular Connectors (Military Connector)

Welcome to NJ AERO, the forefront of circular connector solutions in China. As a trusted industry leader, we bring you the power of advanced MIL-DTL-38999 I series connectors, engineered to meet the highest industry standards.

MS27467T11F98PHN MS27466T25B04PN MS27467T23B53PN Unlock the Potential of MIL-DTL-38999 I Series Connectors with NJ AEROMIL-DTL-38999 I Series circular connectors are military-grade connectors specifically designed for communication purpose. This military connector offers high-density contact arrangements, making it suitable for military vehicles, soldier communication systems, and other connection applications requiring high reliability. These Mil-Spec connectors come in multiple receptacle mounting options to adapt to users' particular application needs.

Our MIL-DTL-38999 I series circular connectors find applications in a wide range of industries where circuit signal connections are crucial.

EnvironmentsOur MIL-DTL-38999 I series circular connectors excel in environments characterized by strong vibrations, sandstorms, and high humidity, making them ideal for demanding conditions.

Main Technical Performance Mechanical Performance Diverse material options for shells, including aluminum alloy, stainless steel, and titanium alloy Insulation components crafted from high-quality thermosetting or thermoplastic materials Silicone rubber sealing gaskets and O-rings for reliable protection Plating finishes tailored to specific requirements: cadmium plating (B-class), stainless steel passivation (E-class), chemical nickel plating (F-class), aluminum alloy matte cadmium plating (FT-class), and titanium alloy (TA-class) Gold-plated copper alloy contacts available in crimp, solder, and printed circuit board configurations Impressive mechanical lifespan of 500 mating cycles Resilience to vibrations, including sinusoidal vibrations (10-2000Hz) at 294m/s² and random vibrations (100-1000Hz) with 1g²/Hz power spectral density Shock resistance against 3ms half-sine wave with peak acceleration up to 300g Environmental Performance Temperature range: B-class (-65 ˚C to 175 ˚C), E and F class (-65 ˚C to 200 ˚C) Salt spray test results: B-class (500 hours), E and TA class (1000 hours), F-class (48/96 hours), FT class (96 hours) High humidity resistance: Up to 98% relative humidity at 40 ˚C Operating altitude: Up to 30,480 meters Electrical Performance Contact Resistance and Current Rating| Contact No. | Diameter (mm) | Resistance(mΩ) | Current (A) |

| 22D | Ø0.76 | ≤12 | 5 |

| 20# | Ø1.00 | ≤5 | 7.5 |

| 16# | Ø1.60 | ≤2.5 | 13 |

| 12# | Ø2.40 | ≤1.5 | 23 |

| 10# | Ø3.15 | ≤1.0 | 40 |

Superior shielding capabilities, with minimum attenuation of 85dB from 100MHz to 1GHz and 50dB from 1GHz to 10GHz

Withstanding voltage (V):| Service rating | M | N | I | II |

| Sea level | 1300 | 1000 | 1800 | 2300 |

| 21000m | 800 | 600 | 1000 | 1000 |

The MIL-DTL-38999 I series circular connectors also demonstrate superior resistance to moisture, salt spray (corrosion), fungi, and dust.

Related Communication ConnectorsMore Electrical ConnectorsLinks:https://www.globefindpro.com/products/189.html

-

Circular Connectors (Military Connector)

Circular Connectors (Military Connector)

-

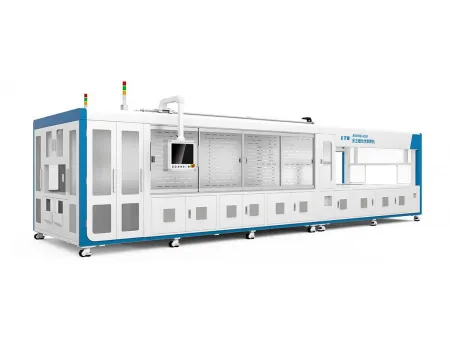

Automatic Edge Taping Machine

Automatic Edge Taping Machine

-

Shank Rods

Shank Rods

-

Rectangular Wrinklewall Aluminum Foil Container, G rim

Rectangular Wrinklewall Aluminum Foil Container, G rim

-

MBB Cell Stringer Machine, AM050E

MBB Cell Stringer Machine, AM050E

-

Electroluminescence and visual inspection system for PV module

Electroluminescence and visual inspection system for PV module

-

Shank Adapters

Shank Adapters

-

Circular Connectors

Circular Connectors

-

Circular Connectors (Military Connector)

Circular Connectors (Military Connector)

-

MF Rods / Male-Female Drill Rods

MF Rods / Male-Female Drill Rods

-

Tapered Drill Bits

Tapered Drill Bits

-

Threaded Button Bits

Threaded Button Bits