Circular Connectors (Military Connector)

MIL-DTL-38999 III Series Applications of Circular Connectors  D38999/26KG11SN D38999/26WB99SN

D38999/26KG11SN D38999/26WB99SN

Insulation resistance: ≥5000MΩ under normal conditions (500VDC) Insulation resistance: ≥5000MΩ under normal conditions (500VDC) Class W: ≤2.5mΩ Class F, FT: ≤1.0mΩ Class K, TA: ≤10mΩ EMI shielding: Minimum attenuation of 85dB from 100MHz to 1GHz (Class F, Class W) EMI shielding: Minimum attenuation of 65dB from 1GHz to 10GHz (Class F), 50dB (Class W) 8# twin coaxial contacts: Frequency bandwidth of 0-20MHz, maximum rated voltage of 500VAC, 125VAC at 21000 meters Voltage drop: Inner and middle contacts ≤55mV at 1A, outer contacts ≤75mV at 12A

Our MIL-DTL-38999 III series circular connectors are ideal for circuit signal connections in various industries.

EnvironmentsOur MIL-DTL-38999 III series circular connectors are designed to thrive in environments characterized by strong vibrations, heavy rain, sandstorms, and high humidity.

Introducing our advanced MIL-DTL-38999 III series connectors, engineered to meet and exceed MIL-DTL-38999 series III specifications.

General Information Compliant with MIL-DTL-38999 III series standards Three-start thread for fast and secure mating, equipped with anti-loosening mechanism Compact size, lightweight design, and high contact density Superior EMI shielding capabilities Removable contacts for easy installation and anti-misinsertion features, preventing bent pins Designed for high-strength vibration and harsh environmental conditions, including strong winds, sand, and humidity 12# and 16# contact arrangements support fiber optic contacts 12#, 10#, and 8# contact arrangements support coaxial and shielded contacts Main Technical Performance Mechanical Performance Shell materials: Aluminum alloy, stainless steel, titanium alloy Insulator materials: Thermosetting or thermoplastic Sealing material: Silicone rubber Plating options: Class W: Cadmium plating Class F: Chemical nickel plating Class K: Stainless steel passivation Class FT: Aluminum alloy with matte cadmium plating Class TA: Titanium alloy Contact materials: Gold-plated copper alloy, available in crimp, solder, and printed circuit board configurations Mechanical lifespan: 500 mating cycles Shock resistance: Withstands 3ms half-sine wave with peak acceleration up to 300g Vibration resistance: Sinusoidal vibration: 60g with temperature cycling and simulated attachments (36 hours) Random vibration at high temperatures: Frequency range of 100-1000Hz, power spectral density of 1g²/Hz, corresponding to an RMS value of 41.7g Random vibration at ambient temperature: Frequency range of 100-1000Hz, power spectral density of 5g²/Hz, corresponding to an RMS value of 49.5g Environmental Performance Temperature range: Class W: -65°C to 175°C Class F, K, FT, TA: -65°C to 200°C Salt spray test results: Class W: 500 hours Class K, TA: 1000 hours Class F: 48 hours/96 hours Class FT: 96 hours Sealing: Complies with MIL-DTL-38999M low-pressure impregnation requirements Humidity resistance: According to MIL-DTL-38999M, 24 hours with 10 cycles Fluid resistance: Resistant to various fuels, coolants, and solvents Electrical Performance Withstanding voltage (V):| Service rating | M | N | I | II |

| Sea level | 1300 | 1000 | 1800 | 2300 |

| 21000m | 800 | 600 | 1000 | 1000 |

Note: Different contact arrangements have different operating levels, see top-right corner of contact arrangement label

Contact resistance and current rating:| Contact ID | Diameter (mm) | Resistance (mΩ) | Current (A) |

| 22D | Ø0.76 | ≤12 | 5 |

| 20# | Ø1.00 | ≤5 | 7.5 |

| 16# | Ø1.60 | ≤2.5 | 13 |

| 12# | Ø2.40 | ≤1.5 | 23 |

| 10# | Ø3.15 | ≤1.0 | 40 |

Scan QR to Read

Links:https://www.globefindpro.com/products/190.html

Links:https://www.globefindpro.com/products/190.html

Recommended Products

-

Automatic Edge Taping Machine

Automatic Edge Taping Machine

-

Shank Rods

Shank Rods

-

Rectangular Wrinklewall Aluminum Foil Container, G rim

Rectangular Wrinklewall Aluminum Foil Container, G rim

-

MBB Cell Stringer Machine, AM050E

MBB Cell Stringer Machine, AM050E

-

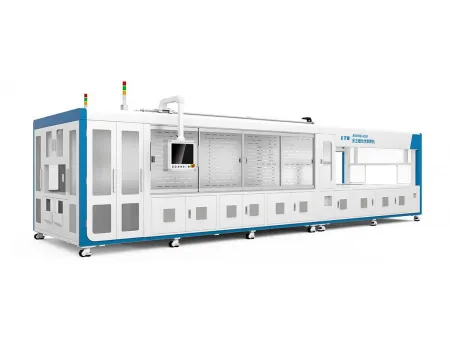

Electroluminescence and visual inspection system for PV module

Electroluminescence and visual inspection system for PV module

-

IQF Fluidized Tunnel Freezer

IQF Fluidized Tunnel Freezer

-

Circular Connectors (Military Connector)

Circular Connectors (Military Connector)

-

Shank Adapters

Shank Adapters

-

Circular Connectors

Circular Connectors

-

Circular Connectors (Military Connector)

Circular Connectors (Military Connector)

-

MF Rods / Male-Female Drill Rods

MF Rods / Male-Female Drill Rods

-

Tapered Drill Bits

Tapered Drill Bits