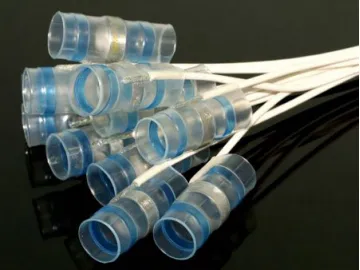

High Temperature Heat Shrink Marker Sleeve

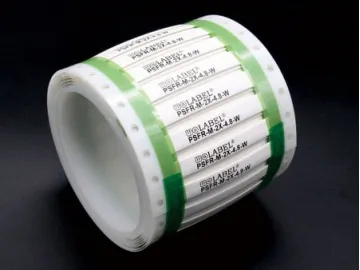

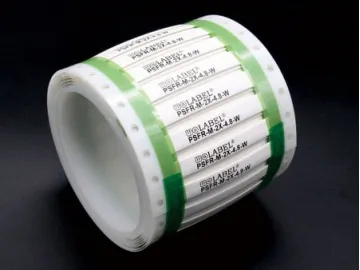

High Temperature Heat Shrink Marker Sleeve, PSFR High-temperature, Heat Shrinkable Identification Sleeves Model: PSFR  Standard

Standard

Dimensions Shrink ratio-2X

Shrink ratio-3X

PSFR-M high temperature heat shrink marker sleeve is a type of heat shrink identification sleeves designed for wire and cable identification in applications with high temperature environments or requiring extreme resistance to fuels, lubricants and cleaning solvents. The PSFR-M high temperature heat shrink marker sleeve is printable using thermal transfer printer, and the identification marks are durable and can remain legible even when exposed to abrasion, aggressive cleaning solvents and industrial fluids.

AMS-DTL-23053/18, SAE-AS 81531, MIL-STD-202F/Method 215J, UL224, RoHS etc.

Features Material: fabricated from irradiated, thermally stabilized, flame retarded, modified PVDF Application: defense, aerospace, mass transit, etc. Operating temperature range: -55℃~ 225℃ Minimum recovery temperature: 135℃ Maximum storage temperature: 50℃ Shrink ratio: 2:1 Color: white, yellow, other colors are available upon request Printing: single sided printing or double sided printing Supplied format: ladder-style or continuous sleeve Recommended printer: thermal transfer printer Recommended ribbon: N85 resin ribbon, black, 100mm(width)×300m(length) Technical Data| Property | Testing Requirement | WOER Results |

| Tensile strength (MPa) | 24.3 | 31.3 |

| Ultimate Elongation (%) | 200 | 330 |

| Low temperature flexibility 4 hours at -55±1℃ | No cracking | Pass(no cracking) |

| Heat shock 4 hours at 275±3℃ | No cracking, flowing or dripping | Pass(no cracking, legible after 100 rubs)) |

| Dielectric strength (kV/mm) | 15.7 | 43.0 |

| Volume Resistivity (Ω.cm) | 1.0×1012minimum | 9.1×1012 |

| Corrosive effect | No corrosive | Pass |

| Flammability | VW-1 | Pass |

| Heat aging 168 hours at 225±2℃ | No cracking, flowing or dripping | Pass(no cracking, legible after 100 rubs) |

| Print performance | SAE-AS 81531 | Pass(legible after 100 rubs) |

| Strokes | MIL-STD-202F | Pass |

| Order Code | As Supplied (mm) | As Supplied (mm) | |||

| ID (D) | Flatten Width (W2) | Double Wall Thickness | ID (d) | Single Wall Thickness | |

| AMS-M-2X-1.6 | 2.00±0.20 | 3.7±0.3 | 0.48±0.10 | ≤0.79 | 0.45±0.06 |

| AMS-M-2X-2.4 | 2.79±0.20 | 5.0±0.3 | 0.48±0.10 | ≤1.18 | 0.49±0.06 |

| AMS-M-2X-3.2 | 3.64±0.23 | 6.3±0.4 | 0.48±0.10 | ≤1.59 | 0.51±0.06 |

| AMS-M-2X-4.8 | 5.26±0.25 | 8.9±0.4 | 0.49±0.10 | ≤2.36 | 0.54±0.06 |

| AMS-M-2X-6.4 | 6.92±0.28 | 11.5±0.4 | 0.50±0.10 | ≤3.18 | 0.56±0.06 |

| AMS-M-2X-9.5 | 10.2±0.32 | 16.7±0.5 | 0.51±0.11 | ≤4.75 | 0.59±0.06 |

| AMS-M-2X-12.7 | 13.5±0.36 | 21.8±0.6 | 0.52±0.11 | ≤6.35 | 0.60±0.07 |

| AMS-M-2X-19- | 20.1±0.40 | 32.2±0.6 | 0.53±0.11 | ≤9.53 | 0.62±0.07 |

| AMS-M-2X-25- | 26.7±0.45 | 42.5±0.7 | 0.55±0.12 | ≤12.7 | 0.63±0.07 |

| AMS-M-2X-38- | 39.8±0.51 | 63.2±0.8 | 0.57±0.12 | ≤19.1 | 0.64±0.07 |

| AMS-M-2X-51- | 53.0±0.56 | 83.9±0.9 | 0.58±0.13 | ≤25.4 | 0.64±0.08 |

| AMS-M-2X-76- | 79.4±0.56 | 125.3±1.0 | 0.59±0.13 | ≤38.1 | 0.64±0.09 |

| Order Code | As Supplied (mm) | As Supplied (mm) | |||

| ID (D) | Flatten Width (W2) | Double Wall Thickness | ID (d) | Single Wall Thickness | |

| AMS-M-3X-1.6- | 2.00±0.20 | 3.7±0.3 | 0.47±0.10 | ≤0.53 | 0.52±0.06 |

| AMS-M-3X-2.4- | 2.79±0.20 | 5.0±0.3 | 0.47±0.10 | ≤0.79 | 0.57±0.06 |

| AMS-M-3X-3.2- | 3.64±0.23 | 6.3±0.4 | 0.48±0.10 | ≤1.06 | 0.61±0.06 |

| AMS-M-3X-4.8- | 5.26±0.25 | 8.9±0.4 | 0.49±0.10 | ≤1.59 | 0.67±0.06 |

| AMS-M-3X-6.4- | 6.92±0.28 | 11.5±0.4 | 0.50±0.10 | ≤2.36 | 0.71±0.06 |

| AMS-M-3X-9.5- | 10.2±0.32 | 16.7±0.5 | 0.52±0.11 | ≤3.18 | 0.77±0.06 |

| AMS-M-3X-12.7 | 13.5±0.36 | 21.8±0.6 | 0.53±0.11 | ≤4.75 | 0.80±0.07 |

| AMS-M-3X-19- | 20.1±0.40 | 32.2±0.6 | 0.55±0.11 | ≤6.35 | 0.84±0.07 |

| AMS-M-3X-25- | 26.7±0.45 | 42.5±0.7 | 0.56±0.12 | ≤8.47 | 0.86±0.07 |

| AMS-M-3X-38- | 39.8±0.51 | 63.2±0.8 | 0.57±0.12 | ≤12.9 | 0.89±0.07 |

| AMS-M-3X-51- | 53.0±0.56 | 83.9±0.9 | 0.57±0.1 | ≤17.2 | 0.90±0.08 |

| AMS-M-3X-76- | 79.4±0.56 | 125.3±1.0 | 0.57±0.13 | ≤25.8 | 0.92±0.09 |

Scan QR to Read

Links:https://www.globefindpro.com/products/1910.html

Links:https://www.globefindpro.com/products/1910.html

Recommended Products

-

Corrugated Conduit / Convoluted Tubing

Corrugated Conduit / Convoluted Tubing

-

Halogen-free LDPE Heat Shrinkable Tubing

Halogen-free LDPE Heat Shrinkable Tubing

-

Halogen-free HDPE Heat Shrinkable Tubing

Halogen-free HDPE Heat Shrinkable Tubing

-

Expandable Sleeving

Expandable Sleeving

-

Self-Closing Sleeving

Self-Closing Sleeving

-

FEP Heat Shrinkable Tubing

FEP Heat Shrinkable Tubing

-

Heat Shrinkable Marker Sleeve

Heat Shrinkable Marker Sleeve

-

IXPE Foam Hiking Seat Pad

IXPE Foam Hiking Seat Pad

-

Diesel Resistant Heat Shrinkable Cable Marker Sleeve

Diesel Resistant Heat Shrinkable Cable Marker Sleeve

-

Special Purpose Heat Shrink Tubing

Special Purpose Heat Shrink Tubing

-

Specialty Heat Shrink Tubing

Specialty Heat Shrink Tubing

-

Specialty Heat Shrink Tubing

Specialty Heat Shrink Tubing