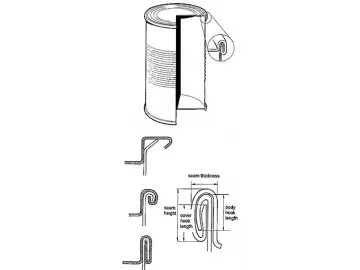

Automatic Can Seamer

Automatic can seamers are used for can sealers, and work in conjunction with can filling machines. STWMF’s can seamers are suitable for a variety of can types, just by changing the dies used.

| Machine type | Application | Speed level | Max. capacity |

| ST-B15 | Food cans | Medium | 400CPM |

| ST-B15APH | Aerosol spray cans | Medium | 180CPM |

| ST-B6CL | Large cans | Medium | 220CPM |

| ST-B15A | Food cans | Medium | 450CPM |

| ST-B83A | Food cans | High | 500CPM |

| ST-B83AS | Small food cans | High | 500CPM |

| ST-C3AL | Food cans, chemical cans | Low | 65CPM |

Scan QR to Read

Links:https://www.globefindpro.com/products/19150.html

Links:https://www.globefindpro.com/products/19150.html

Recommended Products

-

Tinplate Aerosol spray tin

Tinplate Aerosol spray tin

-

SL01 Lighted Full Length Dressing Mirror with Dimmer and Defogger

SL01 Lighted Full Length Dressing Mirror with Dimmer and Defogger

-

SL05 Frameless LED Lighted Full Length Dressing Mirror

SL05 Frameless LED Lighted Full Length Dressing Mirror

-

Two-piece Can Production Line

Two-piece Can Production Line

-

ZL11 Matte Black Round Wall Mirror with Light

ZL11 Matte Black Round Wall Mirror with Light

-

Automatic 6H Double Seamer ST-B15A

Automatic 6H Double Seamer ST-B15A

-

Vertical Sterilizer

Vertical Sterilizer

-

Retort Control System

Retort Control System

-

DF39 Frameless Rectangular Mirror with LED Light

DF39 Frameless Rectangular Mirror with LED Light

-

Three-piece Can Production Line

Three-piece Can Production Line

-

Water Spray Retort

Water Spray Retort

-

Testimonials

Testimonials

Hot Products